Wet Sieving Apparatus - (Fly Ash Testing Apparatus)

Price 1.00 INR/ Piece

Wet Sieving Apparatus - (Fly Ash Testing Apparatus) Specification

- Product Type

- Wet Sieving Apparatus

- Resolution

- 0.01 g on digital balance (if provided)

- Mounting Type

- Bench Type

- Dimension (L*W*H)

- 9 x 10 x 19 Millimeter (mm)

- Operating Voltage

- 230 V AC

- Response Time

- Immediate (manual visual assessment)

- Port Size

- Standard sieve size 75 micron/45 micron sieve

- Display Type

- Not Applicable (no digital display)

- Automation Grade

- Manual

- Interface Type

- Manual

- Features

- Rugged MS body, corrosion-resistant, water-tight sieve assembly

- Equipment Type

- Wet Sieving Apparatus

- Usage

- Cement Testing Equipment

- Application

- Used for determining the fineness of fly ash

- Hardness

- MS construction (standard hardness)

- Test Range

- Fineness of Fly Ash as per IS: 1727

- Specimen Size

- 50 g approx. (standard as per IS)

- Temperature

- 5C to 45C Operating Range

- Power Supply

- 230 V AC, 50 Hz

- Measuring Range

- Up to IS: 1727 Specification

- Max Height

- 19 inch (as per overall dimension)

- Humidity

- Relative Humidity up to 90%

- Frequency

- 50 Hz

- Accuracy

- 1%

- Number of Specimens

- Single at a time

- Capacity

- 1 test per cycle

- Machine Weight

- Approx. 10-14 kg

- Test Speed

- Standard 2800 rpm (motor speed)

- Test Stroke

- Continuous

- Control Mode

- Manual Switch Operation

- Color

- Blue/Grey (powder coated)

- Body Material

- Mild Steel, Powder Coated

- Complies With Standards

- IS: 1727, IS: 3812

- Accessories Included

- Sieve Frame, Collection Pan, Brush, Water Connectors

- Water Supply Required

- Yes, clean water inlet

- Sieve Frame Material

- Brass/Stainless Steel

Wet Sieving Apparatus - (Fly Ash Testing Apparatus) Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- Ahmedabad

- Supply Ability

- 100 Pieces Per Month

- Delivery Time

- 4 Week

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Box / Corrugated Box

- Main Domestic Market

- All India

- Certifications

- ISO 9001 : 2015

About Wet Sieving Apparatus - (Fly Ash Testing Apparatus)

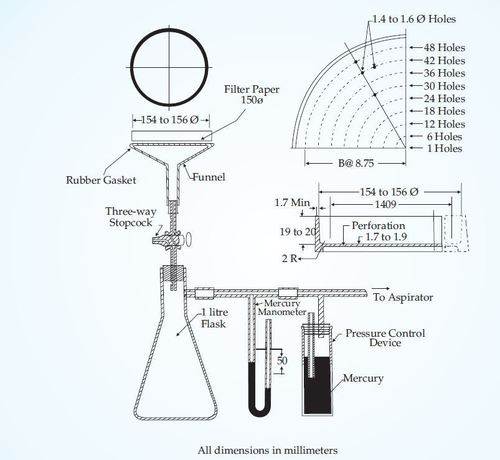

Wet Sieving Apparatus

Wet Sieving Apparatus is used for determining the fineness of fly ash.

Further details available on our website.

The Price mentioned here are subject to change as per the capacity, specifications and application of the user.

Precision Testing for Fly Ash Fineness

Engineered for reliable assessment of fly ash fineness, this apparatus strictly follows IS: 1727 and IS: 3812 standards. The machine accommodates one sample per test cycle, employing continuous wet sieving to ensure accurate classification and granular analysis. Its robust mild steel body is powder-coated, offering both stability and corrosion resistance in laboratory environments.

User-Friendly Operation and Durable Design

The Wet Sieving Apparatus features a manual switch for straightforward control and maintenance. Accessories such as sieve frames, collection pans, and brushes simplify the cleaning and testing process. Built for longevity, its mild steel construction with a water-tight sieve assembly withstands repeated laboratory use, even in high-humidity conditions up to 90%.

FAQs of Wet Sieving Apparatus - (Fly Ash Testing Apparatus):

Q: How is the Wet Sieving Apparatus used in fly ash testing?

A: This apparatus is employed to determine the fineness of fly ash by passing a water-suspended sample through specific brass or stainless steel sieves, as per IS: 1727 and IS: 3812. The manual operation involves loading a 50 g sample, connecting water, and activating the sieving process using the switch for continuous test stroke.Q: What are the advantages of using a mild steel, powder-coated body for this apparatus?

A: The mild steel, powder-coated body enhances durability and provides excellent corrosion resistance, making the apparatus suitable for repeated use in laboratory environments prone to moisture and chemical exposure.Q: When should the sieves and other accessories be cleaned or maintained?

A: After each testing cycle, the sieve frame, collection pan, and brush should be cleaned with water to prevent residue buildup and maintain measurement accuracy. Regular cleaning ensures longevity and repeatable testing conditions.Q: Where should the Wet Sieving Apparatus be installed for optimal performance?

A: It should be bench-mounted in a laboratory setting with access to a clean water inlet, a stable 230 V AC power supply, and ambient conditions within 5C to 45C and up to 90% humidity.Q: What is the main process involved in testing with this equipment?

A: The process entails weighing a fly ash specimen, placing it in the sieve frame, supplying clean water, and operating the machine at a standard 2800 rpm. The fineness is visually assessed once the sample passes through the 75 or 45 micron sieve, providing immediate results.Q: How accurate are the test results and what is the resolution?

A: Results are accurate within 1%, and if a digital balance is used during the preparation or verification stage, it provides a resolution of 0.01 grams.Q: What benefits does this apparatus offer to cement and fly ash testing labs?

A: It delivers reliable, immediate fineness results, helping labs comply with IS standards while ensuring consistent quality assessments. Its rugged build and corrosion resistance make it suitable for busy testing environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Cement Testing Equipment Category

Water Retention Test Apparatus

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Max Height : 350 mm

Control Mode : Manual Control

Measuring Range : 0100% water retention

Number of Specimens : 1

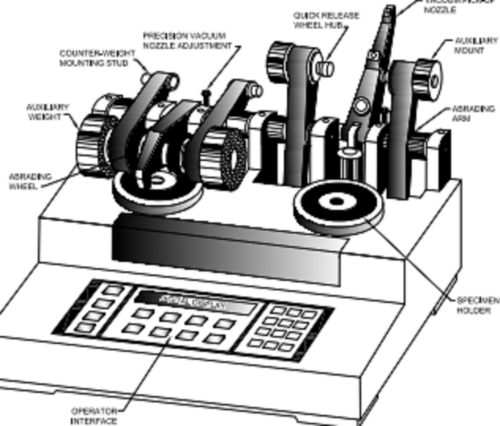

DETERMINATION OF RESISTANCE TO ABRASION

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Max Height : 450 mm

Control Mode : Automatic

Measuring Range : up to 99999 cycles

Number of Specimens : 2

Lime Reactivity Cabinet

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Max Height : 400 mm

Control Mode : Digital Timer Control

Measuring Range : Standard (as per IS specifications)

Number of Specimens : One at a time

MARSH CONE FUNNEL - FOR BENTONITE VISCOSITY

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Max Height : Approx. 350 mm

Control Mode : Manual

Measuring Range : Marsh viscosity 1060 seconds (typical range for bentonite)

Number of Specimens : Single sample per test

|

EIE INSTRUMENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry