Cement Testing Equipments

Price 1.00 INR/ Piece

Cement Testing Equipments Specification

- Features

- Corrosion resistant, heavy-duty, precise measurements

- Usage

- Industrial

- Gas Pressure

- 0.5-1.5 MPa (if applicable)

- Interface Type

- RS232 / USB (optional)

- Application

- Strength, consistency, fineness, setting time, and soundness testing

- Port Size

- Standard 1/4 inch NPT

- Humidity

- Relative humidity 50% 5%

- Max Height

- Up to 250 mm (for some models)

- Automation Grade

- Semi-Automatic/Automatic

- Resolution

- 0.1 N

- Color

- Multi

- Test Range

- Up to 1000 N

- Number of Specimens

- Single/Multiple (based on attachment)

- Mounting Type

- Bench-top

- Temperature

- 10C to 35C

- Hardness

- HRC 55-60 (steel components)

- Measuring Range

- Adjustable, depends on accessory

- Operating Voltage

- 220 V

- Equipment Type

- Cement Testing Equipments

- Product Type

- Cement Testing Equipments

- Response Time

- <2 seconds

- Specimen Size

- 40 x 40 x 160 mm (standard cube/mortar bar)

- Accuracy

- 1%

- Power Supply

- 220-240V AC, 50 Hz

- Frequency

- 50 Hz

- Display Type

- Digital / Analog

- Capacity

- Up to 100 kN

- Machine Weight

- Approx. 50-80 kg (varies by model)

- Test Speed

- 12 mm/min

- Test Width

- 32 mm (for standard specimens)

- Test Stroke

- Up to 60 mm

- Control Mode

- Manual/Automatic

- Operation Mode

- User friendly control panel

- Calibration

- Supplied with calibration certificate

- Accessories Supplied

- Tamping rod, measuring beaker, cube moulds, vibration machine attachment

- Compliance

- IS:4031, ASTM C109, EN 196

- Safety Features

- Overload protection, emergency stop switch

Cement Testing Equipments Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- Ahmedabad

- Payment Terms

- Telegraphic Transfer (T/T), Cash Against Delivery (CAD), Letter of Credit (L/C), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 150 Pieces Per Year

- Delivery Time

- 4 Week

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden packing with strong base

- Main Export Market(s)

- Australia, Africa, Middle East, South America, Asia

- Main Domestic Market

- All India

- Certifications

- ISO 9001 : 2015

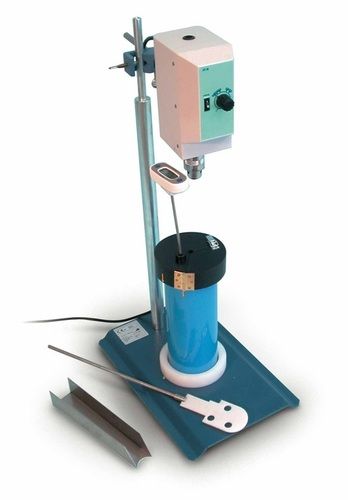

About Cement Testing Equipments

We are here to offer our clients an efficiently working array of Cement Testing Equipments. These are used at construction sites for measuring the workability of the cement and ensure its proper utilization. The equipments are made using best quality stainless steel which give them resistance to impact and corrosion. These include flow table, vibrating table, self-compaction concrete test and many others to name. The Cement Testing Equipments are energy efficient as well as environment friendly. These are easier to operate as well as handle and do not require much involvement of labor. The equipments have longer working life and are dependable.

Features of Cement Testing Equipments:

- Used at construction sites for testing the workability of the cement.

- Can be accessed in customers in different types to meet their requirements.

- Accurate as well as defect free surface finish.

- High tensile strength and have the ability to bear heavy weight without damage.

Advanced Safety for Reliable Operation

Safety is embedded in every aspect of our cement testing equipment, featuring overload protection and emergency stop switches to safeguard both operators and machinery. The control panel is user-friendly, minimizing operational errors. These mechanisms ensure continuous, trouble-free operation for rigorous industrial applications.

Comprehensive Testing and Compliance

Our machines are meticulously engineered to meet IS:4031, ASTM C109, and EN 196 standards, supporting strength, consistency, fineness, setting time, and soundness tests. Supplied with calibration certificates, they guarantee international compliance and result accuracy for quality assurance in all test environments.

Versatile Functionality and Accessories

Each system is delivered with essential accessories including tamping rods, measuring beakers, cube moulds, and vibration machine attachments. With adjustable measuring ranges and support for both manual and automatic control modes, these machines provide broad testing flexibility for single or multiple specimens.

FAQs of Cement Testing Equipments:

Q: How does the overload protection feature in cement testing equipment enhance safety during operation?

A: The overload protection automatically halts the machine if excessive force is detected, preventing potential damage to both the equipment and the specimen. This helps ensure operator safety and prolongs the lifespan of the machine.Q: What calibration process is followed for the supplied cement testing equipment?

A: Each unit is delivered with a calibration certificate, ensuring that measurements meet accuracy standards. Calibration follows the protocols specified in IS:4031, ASTM C109, and EN 196, and is performed before dispatch for immediate usage.Q: When should the emergency stop switch be used on cement testing equipment?

A: The emergency stop switch should be activated in situations where rapid equipment shutdown is necessary, such as unexpected operational issues or safety concerns, to immediately stop all test functions and prevent accidents.Q: Where can the cement testing equipment be installed for optimal performance?

A: These machines are designed for bench-top mounting in industrial laboratory settings with controlled temperature (10C to 35C) and relative humidity (50% 5%) to maintain accuracy and prevent corrosion.Q: What is the process for testing cement strength using this equipment?

A: Typical strength tests involve preparing specimens using supplied cube moulds and accessories, applying controlled loads via manual or automatic modes (up to 100 kN capacity), and monitoring results on digital or analog displays with fast response times and high resolution.Q: How are results displayed and stored on the cement testing equipment?

A: Results are shown on either digital or analog displays, with optional RS232 or USB interfaces enabling data export and analysis for efficient record-keeping and quality control.Q: What are the key benefits of using these cement testing machines in industrial environments?

A: Users benefit from precise measurements, robust construction, corrosion resistance, compliance with major standards, intuitive controls, flexible automation, and comprehensive accessory supportmaking them reliable, efficient solutions for cement quality assessment.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Cement Testing Equipment Category

Wet Sieving Apparatus - (Fly Ash Testing Apparatus)

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : Wet Sieving Apparatus

Power Supply : 230 V AC, 50 Hz

Application : Used for determining the fineness of fly ash

Usage : Cement Testing Equipment

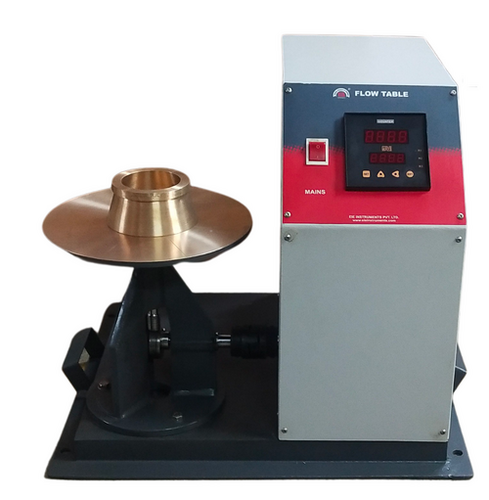

FLOW TABLE MOTORISED for Cement

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : Flow Table Motorized for Cement

Power Supply : 230 V AC, 50 Hz, single phase

Application : Flow test for cement and mortar

Usage : Cement Testing Equipment

Lime Reactivity Test Apparatus

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : Cement Testing Equipment`

Power Supply : 230 V AC, 50 Hz

Application : Used for determining the reactivity on slaking of ground quicklime.

Usage : Cement Testing Equipment

CEMENT MORTAR FLEXURAL TESTING JIG

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Number

Product Type : Cement Mortar Flexural Testing Jig

Power Supply : Not required (Manual jig)

Application : The compression/UTM Machine shall be capable enough to exert 50 N/S loading rate for accurate results as per above listed EN Standards.

Usage : For Cement Testing

|

EIE INSTRUMENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry