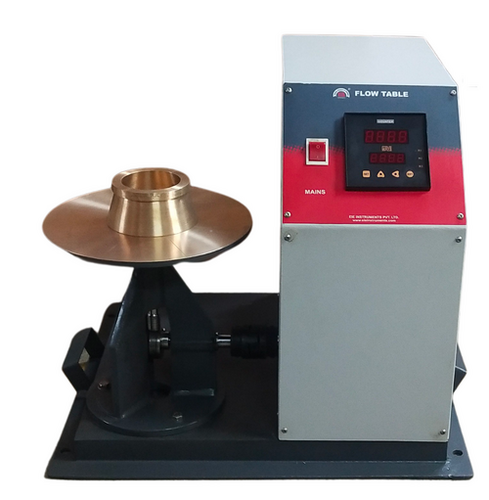

FLOW TABLE MOTORISED for Cement

Price 1.00 INR/ Piece

FLOW TABLE MOTORISED for Cement Specification

- Usage

- Cement Testing Equipment

- Equipment Type

- Flow Table Motorised

- Operating Voltage

- 230 V AC

- Number of Specimens

- One per operation

- Max Height

- 270 mm

- Product Type

- Flow Table Motorized for Cement

- Resolution

- 1 mm

- Specimen Size

- 100 mm cone (as per standards)

- Temperature

- 5C to 40C

- Accuracy

- 1 mm

- Interface Type

- Manual push-button start

- Hardness

- Hardened tabletop for long life

- Response Time

- Immediate/direct

- Features

- Corrosion-resistant tabletop, non-slip base, automatic count

- Automation Grade

- Semi-automatic

- Test Range

- Standard cement flow tests

- Measuring Range

- Conforms to IS/BS/ASTM standards

- Humidity

- Up to 80% RH, non-condensing

- Power Supply

- 230 V AC, 50 Hz, single phase

- Frequency

- 50 Hz

- Display Type

- Analog/dial

- Application

- Flow test for cement and mortar

- Mounting Type

- Bench-top

- Dimension (L*W*H)

- 150 X 360 X 270 (L X W X D) mm Millimeter (mm)

- Capacity

- Suitable for standard cement tests

- Machine Weight

- 20 kg (approx.)

- Test Speed

- 15 drops in 15 seconds

- Test Width

- 250 mm diameter

- Test Stroke

- 12.5 mm drop height

- Control Mode

- Motorised automatic operation

- Finish

- Powder coated frame for durability

- Accessories Provided

- Flow mould and tamping rod

- Material of Tabletop

- Polished brass or stainless steel

- Drop Counter

- Automatic digital counter

FLOW TABLE MOTORISED for Cement Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 100 Pieces Per Month

- Delivery Time

- 8 Week

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Box / Corrugated Box

- Certifications

- ISO 9001 : 2015

About FLOW TABLE MOTORISED for Cement

The flow table consist of a brass table top mounted on a rigid stand. The table top is reinforced with equally disposed ribs and allowed to drop through 12 mm by a ground and hardened cam, Complete with mould. The cam shaft is rotated at the rate of 100 RPM by an electric motor. Suitable for operation on 230 Volts 50 cycles.Further details availableon our website.

The Price mentioned here are subject to change as per the capacity,specifications and application of the user.

Precision Engineered for Reliable Cement Testing

Equipped with a motorized, automatic operation and a digital drop counter, the Flow Table ensures highly accurate flow measurements of cement and mortar mixes. The 12.5 mm drop height and precise control mode facilitate adherence to key industry standards. The corrosion-resistant brass or stainless steel tabletop, paired with a powder-coated frame, provides both longevity and easy maintenance even in high-humidity environments.

User-Friendly, Semi-Automatic Operation

Featuring immediate response time and single push-button operation, this bench-top machine streamlines the testing process. Its automatic count mechanism, clear dial display, and included tamping rod and flow mould ensure users can perform standardized cement flow tests quickly and accurately. With a non-slip base and hardened tabletop, durability and user safety are prioritized in every use.

Versatile and Standard-Compliant Applications

Designed for use by exporters, manufacturers, suppliers, traders, and service providers in India and beyond, this motorized flow table is ideal for laboratories and industrial settings requiring accurate measurement of cement and mortar flow consistency. Its measuring range conforms to IS/BS/ASTM standards, making it a dependable solution for quality control and research activities.

FAQs of FLOW TABLE MOTORISED for Cement:

Q: How is the FLOW TABLE MOTORISED for Cement operated?

A: The FLOW TABLE MOTORISED features a semi-automatic, motorized mechanism. Users simply place the specimen in the provided flow mould, start the test with the manual push-button, and the machine automatically delivers 15 calibrated drops in 15 seconds, with results recorded on the analog/dial display.Q: What materials are available for the flow tables tabletop, and how does this benefit users?

A: The tabletop comes in either polished brass or stainless steel, both of which provide corrosion resistance and a hardened surface for longevity. This ensures accurate and repeatable results for each test under various laboratory conditions.Q: When should you use this machine for cement testing?

A: Use the Flow Table Motorised whenever you need to determine the workability or flow characteristics of cement or mortarwhether for research, quality control, or compliance with IS/BS/ASTM standards.Q: Where can this equipment be installed and used?

A: This bench-top machine is designed for use in cement or construction material testing laboratories, educational institutions, and industrial quality control departments. Its compact size and 20 kg weight make it suitable for most lab benchtops.Q: What is the process for conducting a flow test using this equipment?

A: Place your 100 mm cone specimen in the flow mould on the tabletop. Use the tamping rod as per standards, then start the motorized drop sequence with the push-button. The automatic counter tracks the drops, and the results can be read immediately on the dial.Q: How accurate and reliable are the test results from this equipment?

A: The Flow Table Motorised ensures high accuracy with a 1 mm margin and a precise 1 mm resolution. The automatic counter and standardized drop mechanism minimize user error and ensure consistent, reproducible results.Q: What are the key benefits of using this motorized flow table for cement testing?

A: Key benefits include enhanced precision, automatic operation for improved repeatability, quick setup and testing, corrosion-resistant materials for durability, and compliance with major international testing standards.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Cement Testing Equipment Category

Wet Sieving Apparatus - (Fly Ash Testing Apparatus)

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Cement Testing Equipment

Product Type : Wet Sieving Apparatus

Application : Used for determining the fineness of fly ash

Features : Rugged MS body, corrosionresistant, watertight sieve assembly

CEMENT MORTAR FLEXURAL TESTING JIG

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Number

Usage : For Cement Testing

Product Type : Cement Mortar Flexural Testing Jig

Application : The compression/UTM Machine shall be capable enough to exert 50 N/S loading rate for accurate results as per above listed EN Standards.

Features : Universal compatible with UTM/compression machines, heavyduty steel construction

COMPRESSION FRAME JIG ASSEMBLY

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : For Cement Testing

Product Type : Compression Frame Jig Assembly

Application : This jig is designed for testing of 40 x 40 x 160mm cement prism after breaking in Flexure and also can be adapted with 50mm platen to test 2 or 50mm mortar cement cube specimen

Features : Rugged steel body, precision alignment, simple operation, reusable

CEMENT MORTAR PERMEABILITY APPARATUS

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Cement Testing Equipment

Product Type : Cement Mortar Permeability Apparatus

Application : The test method is for determining the permeability to water of pozzolana mortar prepared and cured under specified conditions, by measuring the percolation of water through standard cylindrical specimens.

Features : Heavy gauge powder coated body, three permeability cells, pressure gauge, water reservoir, connecting pipes, easy operation.

|

EIE INSTRUMENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry