CEMENT MORTAR FLEXURAL TESTING JIG

Price 1.00 INR/ Piece

CEMENT MORTAR FLEXURAL TESTING JIG Specification

- Usage

- For Cement Testing

- Max Height

- 250 mm

- Humidity

- Ambient

- Power Supply

- Not required (Manual jig)

- Display Type

- Depends on UTM/compression machine

- Product Type

- Cement Mortar Flexural Testing Jig

- Resolution

- 0.01 kN (machine-dependent)

- Hardness

- High grade steel, HRC 60-62

- Temperature

- Ambient

- Specimen Size

- 40 mm x 40 mm x 160 mm

- Number of Specimens

- Single specimen at a time

- Test Range

- 0 - 150 kN (dependent on applied UTM/Compression machine)

- Application

- The compression/UTM Machine shall be capable enough to exert 50 N/S loading rate for accurate results as per above listed EN Standards.

- Measuring Range

- 0 - 150 kN (machine-dependent)

- Mounting Type

- Placed on compression/UTM machines

- Features

- Universal compatible with UTM/compression machines, heavy-duty steel construction

- Port Size

- Compatible with standard Compression/UTM machine platens

- Automation Grade

- Manual

- Accuracy

- 1% (dependent on UTM/compression machine)

- Response Time

- Immediate (manual jig)

- Interface Type

- Mechanical/Physical

- Equipment Type

- Flexural Testing Jig

- Dimension (L*W*H)

- 205 X 205 X 250 (L X W X D) mm Millimeter (mm)

- Capacity

- Up to 150 kN

- Machine Weight

- Approx. 8 Kg

- Test Speed

- 50 N/s loading rate

- Test Width

- 40 mm

- Test Stroke

- 100 mm

- Control Mode

- Manual operation

- Construction Material

- High quality hardened steel

- Compatibility

- Fits standard 40 mm x 40 mm x 160 mm cement mortar specimens

- Jig Type

- Three-point flexural testing

- Maintenance

- Minimal required; periodic cleaning and lubrication

- Surface Finish

- Polished/Anti-rust coated

- Clamping Method

- Mechanical clamping and sliding base

- Color

- Metallic (silver)

- Specimen Placement

- Three-point loading system

- Safety

- No electrical parts, fully mechanical operation

CEMENT MORTAR FLEXURAL TESTING JIG Trade Information

- Minimum Order Quantity

- 1 Number

- Supply Ability

- 100 Per Month

- Delivery Time

- 4 Week

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Box / Corrugated Box

- Certifications

- ISO 9001 : 2015

About CEMENT MORTAR FLEXURAL TESTING JIG

Details:

- The flexural Jig is designed for testing of 40 x 40 x 160mm cement prism

- Robust frame fitted with an upper bearer that moves vertically supported by springs.

- One of the two lower bearer can tilt horizontally and the distance between the two bearers is 100 mm.

Further details availableon our website.

The Price mentioned here are subject to change as per the capacity,specifications and application of the user.

Precision & Durable Construction

Manufactured from high-grade steel (HRC 60-62) with a polished, anti-rust finish, this flexural testing jig offers exemplary strength and reliability. The mechanical clamping system and sturdy sliding base ensure that specimens are secured precisely for accurate testing every time.

Effortless Compatibility & Manual Operation

This jig is universally compatible with all standard UTM/compression machines equipped with 40 mm platens. Its manual operation means there are no electrical hazards or complicated setupsimply mount, secure your sample, and begin testing with total control.

Low-Maintenance & User-Friendly Design

Maintenance is minimal, requiring only periodic cleaning and light lubrication. The fully mechanical interface, absence of power requirements, and robust material selection result in long service life, reliable results, and ease of use for any laboratory or field setting.

FAQs of CEMENT MORTAR FLEXURAL TESTING JIG:

Q: How is a cement specimen placed and secured in the flexural testing jig?

A: The specimen is positioned on the three-point loading system using the mechanical clamping and sliding base. This setup ensures the 40 mm x 40 mm x 160 mm cement mortar specimen remains stable during the flexural test for precise results.Q: What are the main benefits of using this flexural testing jig?

A: Key benefits include high accuracy (1% when paired with compatible machines), complete manual operation (no power needed), universal compatibility with UTM/compression machines, and robust construction for long-lasting performance.Q: When and where should the testing jig be used?

A: This jig is ideal for laboratory and site environments where cement mortar flexural strength needs assessment. Its suitable for any setting that has a compatible compression/UTM machine capable of 50 N/s loading, according to EN standards.Q: What is the process for performing a flexural strength test using this jig?

A: To begin, mount the jig onto the compression/UTM machine platens. Place and secure the mortar specimen using the provided clamping system. Manually control the loading at the specified 50 N/s rate, observing results as measured by your compression or UTM machine.Q: How much maintenance does the jig require?

A: Maintenance is minimal and mainly involves regular cleaning of surfaces and occasional light lubrication of moving parts. No electrical parts mean fewer wear points and enhanced reliability.Q: What types and sizes of specimens does this jig accommodate?

A: This jig is designed to fit single cement mortar specimens with dimensions of 40 mm x 40 mm x 160 mm, complying with standard requirements for cement testing applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Cement Testing Equipment Category

Cement Testing Equipments

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Display Type : Digital / Analog

Power Supply : 220240V AC, 50 Hz

Max Height : Up to 250 mm (for some models)

Usage : Industrial

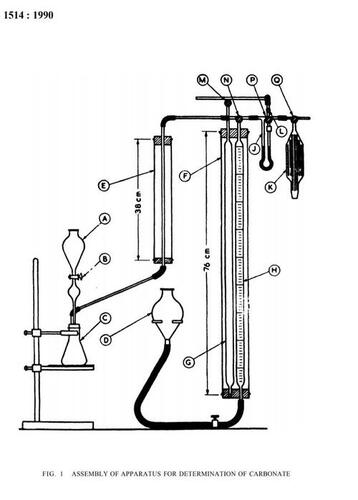

ASSEMBLY OF APPARATUS FOR DETERMINATION OF CARBONATE

Price 1.00 INR / Piece

Minimum Order Quantity : 1 , , Piece

Display Type : Visual (Burette Scale)

Power Supply : Not Required (Manual)

Max Height : 250 mm

Usage : Determination of Carbonate content in Lime and Cement

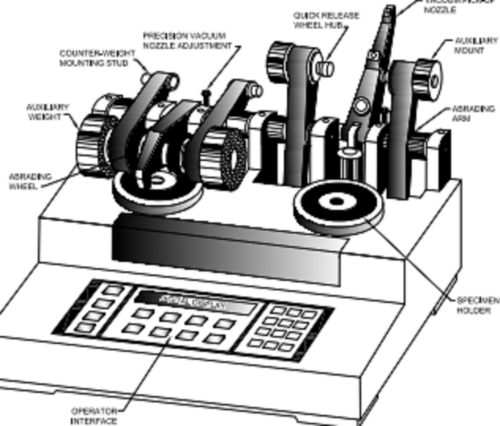

DETERMINATION OF RESISTANCE TO ABRASION

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Display Type : Digital

Power Supply : 220240V, 50Hz

Max Height : 450 mm

Usage : laboratory

Southard Viscometer

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Display Type : None (Manual Reading)

Power Supply : Not Required (Manual Operation)

Max Height : 150 mm (Approximate)

Usage : Cement Testing Equipment

|

EIE INSTRUMENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry