DETERMINATION OF RESISTANCE TO ABRASION

Price 1.00 INR/ Piece

DETERMINATION OF RESISTANCE TO ABRASION Specification

- Material

- stainless steel

- Display Type

- Digital

- Interface Type

- Touch panel

- Test Range

- 099999 cycles

- Frequency

- 50 Hz

- Number of Specimens

- 2

- Gas Pressure

- 0.5-0.8 MPa

- Port Size

- 1/4 inch

- Max Height

- 450 mm

- Specimen Size

- 25 mm x 25 mm

- Application

- Industrial

- Equipment Type

- DETERMINATION OF RESISTANCE TO ABRASION AS PER IS 17190-2020

- Measuring Range

- up to 99999 cycles

- Temperature

- 10C35C

- Power Supply

- 220-240V, 50Hz

- Features

- Corrosion resistant

- Product Type

- DETERMINATION OF RESISTANCE TO ABRASION AS PER IS 17190-2020

- Response Time

- Immediate

- Accuracy

- 1 cycle

- Usage

- laboratory

- Humidity

- 20%80% RH

- Hardness

- 5662 HRC

- Mounting Type

- Bench-top

- Resolution

- 1 cycle

- Automation Grade

- Automatic

- Voltage

- 220-240 Volt (v)

- Operating Voltage

- 220-240 V

- Capacity

- 2 stations

- Machine Weight

- 40 Kg

- Test Speed

- 60 cycles/min

- Test Width

- 25 mm

- Test Stroke

- 35 mm

- Control Mode

- Automatic

- Dimensions (LxWxH)

- 550 x 350 x 450 mm

- Finish

- Polished

- Fixture Type

- Precision specimen clamps

- Abrasive Material

- Standard emery sheet

- Standards Compliance

- IS 17190-2020

DETERMINATION OF RESISTANCE TO ABRASION Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 10 Pieces Per Month

- Delivery Time

- 7-10 Days

- Main Domestic Market

- All India

About DETERMINATION OF RESISTANCE TO ABRASION

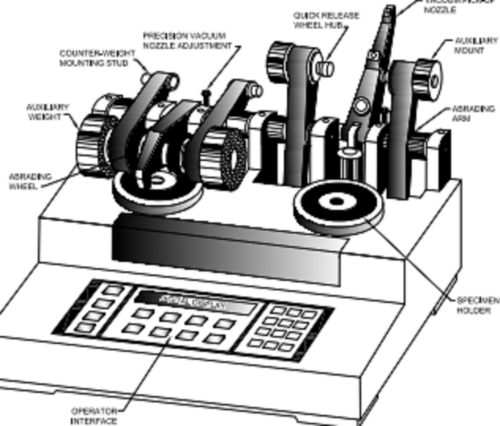

Double head Abrader as shown inFig. 4 and Fig. 5 of IS 17190 or equivalent model with roller wheels, supplementary weights,vacuum suction portion, cleaner brush, screw driver for specimen platform.

- Two modes : Refacing mode and testing mode

- Testing speed : 60 RPM

- No. of abrasion cycles : 300

Purpose-Built for Abrasion Testing

Engineered specifically for testing resistance to abrasion, this machine fulfills strict compliance with IS 17190-2020 standards. Its sturdy stainless steel construction and automated precision clamps ensure repeatable, accurate results for laboratory and industrial applications. The user-friendly touch panel streamlines process control, while its polished finish and durable build ensure longevity and reliability in continuous testing environments.

Automatic Operation with Advanced Controls

Enjoy seamless operation with fully automatic controls and a responsive digital display. The equipment handles two test specimens simultaneously, offering a high degree of repeatability and ease of use. With a resolution and accuracy of 1 cycle, results are immediate and easy to interpret. Its automation minimizes manual intervention, boosting productivity in quality control and R&D laboratories.

FAQs of DETERMINATION OF RESISTANCE TO ABRASION:

Q: How is the resistance to abrasion measured using this equipment?

A: Resistance to abrasion is measured by mounting specimens using precision clamps and subjecting them to a controlled abrasive action with a standard emery sheet. The equipment tracks the number of abrasion cycles (up to 99,999), with results displayed digitally for precise analysis as per IS 17190-2020.Q: What are the benefits of using an automatic, touch-panel interface for abrasion testing?

A: The automatic touch-panel interface allows for quick test setup, immediate cycle readings, and easy adjustment of parameters. This streamlines the testing process, reduces operator errors, and improves workflow efficiency in laboratory and industrial settings.Q: When should this abrasion resistance tester be used?

A: This equipment should be used whenever standardized, repeatable assessment of material durability against abrasive wear is required, especially during quality control, R&D, or product development of coatings, fabrics, or surface treatments.Q: Where is the ideal installation location for the abrasion resistance machine?

A: The machine is designed for laboratory bench-top installation in controlled environments, such as quality assurance labs, research institutions, or industrial testing facilities, where stable power, temperature, and humidity conditions are maintained.Q: What is the standard process for conducting an abrasion resistance test on this machine?

A: The process begins by preparing two 25 x 25 mm specimens, securing them in the precision clamps, and setting up the test parameters via the touch panel. The machine then automatically performs abrasion cycles at a speed of 60 cycles/min across a 25 mm width, recording results until the preset number of cycles or failure endpoint is reached.Q: How does this equipment ensure accurate and reliable test results?

A: Accuracy is ensured with automatic digital control, an immediate response system, 1 cycle measurement precision, and consistent test environments. The robust, corrosion-resistant stainless steel build reduces variability, guaranteeing reliable data across repeated tests.Q: What are the key advantages of this model for users in India?

A: As an Indian exporter, manufacturer, and supplier, this equipment meets national standards (IS 17190-2020), features a main power supply compatibility (220-240V, 50Hz), and offers reliable service across Indian labs and industries. Its automated, user-centric design enhances productivity and minimizes maintenance requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Cement Testing Equipment Category

Heat Of Hydration Apparatus

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Features : Copper calorimeter, outer jacket, insulated body, precise temperature measurement, corrosion resistant

Product Type : Heat of Hydration Apparatus

Usage : Cement Testing Equipment

Application : Used to determine the heat of hydration of low heat Portland and hydraulic cement

CEMENT MORTAR FLEXURAL TESTING JIG

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Number

Features : Universal compatible with UTM/compression machines, heavyduty steel construction

Product Type : Cement Mortar Flexural Testing Jig

Usage : For Cement Testing

Application : The compression/UTM Machine shall be capable enough to exert 50 N/S loading rate for accurate results as per above listed EN Standards.

Accelerated Curing Tank

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Features : Double Walled Construction, Water Circulation, Digital Temperature Control

Product Type : Accelerated Curing Tank

Usage : Industrial

Application : Curing of Concrete Test Specimens

Curing Tank for Cement Mortar Cubes

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Features : Fitted with digital temperature controller, overflow and drainage facility

Product Type : Curing Tank for Cement Mortar Cubes

Usage : For Cement Testing

Application : FOR CONDITIONING OF CEMENT TEST SAMPLES

|

EIE INSTRUMENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry