Southard Viscometer

Price 1.00 INR/ Piece

Southard Viscometer Specification

- Temperature

- Ambient

- Equipment Type

- Southard Viscometer

- Humidity

- Ambient

- Mounting Type

- Bench-top

- Product Type

- Southard Viscometer

- Power Supply

- Not Required (Manual Operation)

- Resolution

- 1 ml

- Automation Grade

- Manual

- Hardness

- Stainless Steel Vessel: 60 HRB

- Test Range

- Consistency and Volume Yield of Putty/Cement

- Usage

- Cement Testing Equipment

- Operating Voltage

- None (Manual)

- Response Time

- Immediate

- Max Height

- 150 mm (Approximate)

- Accuracy

- 2 ml

- Display Type

- None (Manual Reading)

- Measuring Range

- Consistency of Putty/Cement

- Features

- Robust Construction, Corrosion Resistant Vessel, Easy Cleaning

- Number of Specimens

- Single at a time

- Port Size

- Standard Vessel Opening

- Application

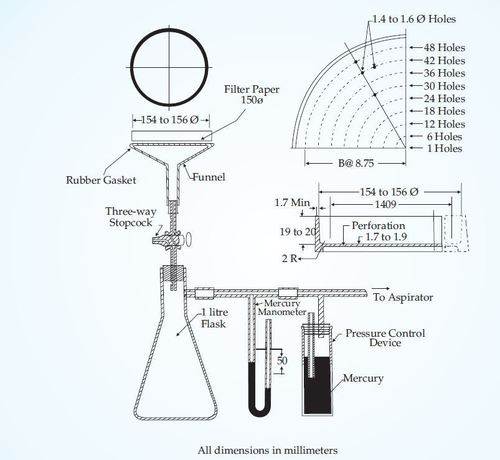

- The Southard viscosimeter shall be used for adjusting the consistency of the putty and a vessel of the shape and dimensions which shall be used for the determination of the volume yield.

- Specimen Size

- Standard Putty/Cement Volume

- Capacity

- Approx. 500 ml vessel

- Machine Weight

- 8 kg

- Test Speed

- Standard (Manual Discharge)

- Test Width

- Approximately 60 mm (Vessel Diameter)

- Control Mode

- Manual

- Operation

- Manual Discharge Mechanism

- Cleaning Method

- Simple manual cleaning

- Included Accessories

- Consists of vessel, discharge apparatus and collection tray

- Transportability

- Portable

- Finish Type

- Polished Metal Finish

- Conformance Standards

- IS 4031 (Part 6)

- Outer Material

- Stainless Steel

- Shape

- Cylindrical Vessel

Southard Viscometer Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- Ahmedabad

- Supply Ability

- 1 Piece Per Month

- Delivery Time

- 4 Week

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Box / Corrugated Box

- Main Export Market(s)

- Australia, Middle East, Africa, South America, Asia

- Main Domestic Market

- All India

- Certifications

- ISO 9001 : 2015

About Southard Viscometer

Southard Viscometer, manufactured, supplied and exported by us is provided with lime putty consistency. It can be effortlessly adjusted with ease. This is designed for a simple degree measurement and allows for simple installation and maintenance. Southard Viscometer Southard Viscometer is capable to measure the lime putty density vessel. It provides high output rate and provides exceptional performance in various applications. The said instrument can measure the precise viscosities for different fluids. This is a small &transferrable instrument, which is featured with capillary tubes.

Furtherdetails available on our website.

The Price mentioned here are subject to change as per the capacity,specifications and application of the user.

High-Performance Cement Consistency Testing

Engineered to facilitate reliable adjustment of putty and cement consistency, the Southard Viscometer employs a manual discharge mechanism for direct measurement. Its stainless steel body and polished finish ensure long-lasting utility and resistance to corrosion, while the devices portability enables use both in laboratory and on-site settings.

Compliance and Durability

The viscometer is manufactured in accordance with IS 4031 (Part 6), guaranteeing standardization in test results. Its construction with high hardness stainless steel provides durability and excellent resistance to chemical environments encountered during cement testing, ensuring stability over repeated use.

Effortless Cleaning and Operation

Designed for convenience, the Southard Viscometers simple manual cleaning process, together with its manual operation and bench-top mounting, makes it easy to maintain and operate, with immediate response times and straightforward handling for single-specimen testing tasks.

FAQs of Southard Viscometer:

Q: How is the Southard Viscometer used for cement consistency testing?

A: The Southard Viscometer is employed by manually discharging a standard volume of putty or cement into its cylindrical vessel. The consistency is then measured by observing the flow and volume yield, following IS 4031 (Part 6) procedures. All readings are taken manually, thanks to the devices intuitive design.Q: What makes the Southard Viscometer suitable for laboratory and site testing?

A: Its portable 8 kg construction, polished stainless steel body, and ambient temperature/humidity operation enable easy transport and use in varied environments. The bench-top mounting and manual control mode further enhance its flexibility for both laboratory and on-site cement testing.Q: How is the cleaning process for the Southard Viscometer performed?

A: Cleaning is straightforward and manual. After each test, simply disassemble the vessel, discharge apparatus, and collection tray, then wipe each part with a cloth or mild cleaning solution. The corrosion-resistant stainless steel body ensures easy maintenance and longevity.Q: What are the benefits of using a manual discharge mechanism in this viscometer?

A: The manual discharge mechanism provides immediate response, full control over test flow, and eliminates dependency on external power sources. This enables consistent, accurate testing of one specimen at a time, with a measuring accuracy of 2 ml.Q: When should this viscometer be used during cement testing?

A: The Southard Viscometer is typically used when adjusting putty consistency and measuring volume yield. It is most applicable during quality control checks, formulation development, or whenever precise consistency measurements are needed.Q: Where can the Southard Viscometer be sourced in India?

A: This equipment is available through various exporters, manufacturers, suppliers, service providers, and traders specializing in cement testing instruments across India. Contact your preferred vendor for specific details and supply options.Q: What distinguishes the Southard Viscometer from automated or powered devices?

A: Unlike automated models, the Southard Viscometer relies on manual operation, requiring no external power. It offers immediate measurements, easy transport, greater durability, and simpler cleaning, making it a reliable choice for basic cement consistency testing tasks.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Cement Testing Equipment Category

Water Retention Test Apparatus

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Application : To determine water retention value of cement mortar, masonry, and plaster

Features : Corrosion resistant, robust body, easy to operate

Usage : Laboratory, testing of mortar/plaster/cement

Automation Grade : Manual

Lime Reactivity Cabinet

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Application : Testing reactivity of hydrated lime as per IS 6932

Features : Digital timer, Stainless steel construction, Inbuilt temperature control

Usage : Laboratory reactivity test

Automation Grade : Semiautomatic

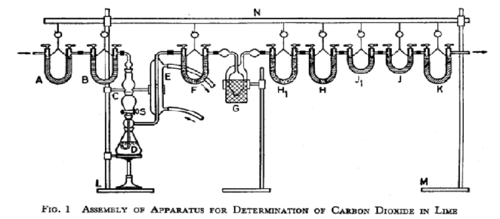

Assembly Of Apparatus For Determination Of Carbon Dioxide in Lime

Price 80720 INR / Unit

Minimum Order Quantity : 1 Piece

Application : Covers method of test for determination of carbon dioxide content of building lime.

Features : Corrosionresistant glassware, easy cleaning, chemical compatibility

Usage : Cement Testing

Automation Grade : Manual

CEMENT MORTAR PERMEABILITY APPARATUS

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Application : The test method is for determining the permeability to water of pozzolana mortar prepared and cured under specified conditions, by measuring the percolation of water through standard cylindrical specimens.

Features : Heavy gauge powder coated body, three permeability cells, pressure gauge, water reservoir, connecting pipes, easy operation.

Usage : Cement Testing Equipment

Automation Grade : Manual

|

EIE INSTRUMENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry