Accelerated Curing Tank

Price 1.00 INR/ Piece

Accelerated Curing Tank Specification

- Port Size

- Standard Outlet/Drain Fitting

- Color

- Silver

- Application

- Curing of Concrete Test Specimens

- Test Range

- Curing Duration: 1 hour to 99 hours (Adjustable Timer)

- Accuracy

- 1C (Temperature)

- Mounting Type

- Floor Mounted

- Automation Grade

- Semi-Automatic

- Operating Voltage

- 230V AC

- Usage

- Industrial

- Display Type

- Digital (LED/LCD)

- Specimen Size

- 150 x 150 x 150 mm (Standard Cube Moulds)

- Equipment Type

- Accelerated Curing Tank

- Temperature

- Ambient to 100C (adjustable)

- Max Height

- 600 mm (approx.)

- Number of Specimens

- 6 to 12 Moulds (150 x 150 x 150 mm)

- Features

- Double Walled Construction, Water Circulation, Digital Temperature Control

- Humidity

- Ambient

- Power Supply

- 230 V AC, 50 Hz, Single Phase

- Product Type

- Accelerated Curing Tank

- Response Time

- Immediate (for Heating)

- Frequency

- 50 Hz

- Interface Type

- Manual/Digital Control Panel

- Resolution

- 0.1C (Temperature Controller Display)

- Capacity

- 6 Cubes/12 Cubes (as per configuration)

- Machine Weight

- 90 kg (approx.)

- Control Mode

- Temperature Controller with Digital Display

- Water Circulation System

- Integral Pump with Uniform Distribution

- Heating Element

- Immersion Water Heater (High Quality)

- Insulation

- Glass Wool/Ceramic

- Tank Dimensions (L x W x H)

- 900 x 600 x 600 mm (Approx.)

- Safety Features

- Over Temperature Protection, Low Water Level Cut-off

- Lid Type

- Stainless Steel Hinged Cover

- Outer Body Material

- Mild Steel (Powder Coated)

- Inner Chamber Material

- Stainless Steel (SS304)

Accelerated Curing Tank Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- Ahmedabad

- Supply Ability

- 100 Pieces Per Month

- Delivery Time

- 8 Week

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Box / Corrugated Box

- Main Export Market(s)

- Australia, Middle East, South America, Asia, Africa

- Main Domestic Market

- All India

- Certifications

- ISO 9001 : 2015

About Accelerated Curing Tank

We bring forth a wide array of Accelerated Curing Tank. This tank is widely used in concrete testing applications. Our offered tank is highly acknowledged for its easy operation, corrosion resistance and longer service life. This tank is precisely engineered by a team of skilled workforce incorporating latest technology. To ensure its flawless performance, this tank is stringently checked on various parameters by a team of quality experts.

Accelerated Curing Tank for cubes are available in wide range such as : 1) 3 Cubes of 150MM 2) 6 Cubes of 150 MM 3) 9 Cubes of 150 MM 4) 12 Cubes of 150 MM 5) 24 Cubes of 150 MM and 6) 36 Cubes of 150 MM

Further details availableon our website.

The Price mentioned here are subject to change as per the capacity,specifications and application of the user.

Advanced Curing Performance

With an optimized heating and circulation system, the Accelerated Curing Tank guarantees uniform temperature distribution for every specimen. The adjustable digital controller enables tight regulation with 1C accuracy, suitable for precise concrete strength testing. Its semi-automatic operation and immediate heating response enhance productivity in high-throughput environments.

Durable and Efficient Design

Constructed with a stainless steel inner chamber and double-walled insulation (glass wool or ceramic), this curing tank minimizes heat loss while resisting corrosion. The powder-coated mild steel outer shell further adds to the equipments durability, making it suitable for long-term industrial use and heavy-duty applications.

Intuitive Operation and Safety

Operators benefit from a user-friendly manual/digital control panel, easy specimen loading via the hinged cover, and clear LED/LCD temperature displays for ongoing monitoring. Built-in safety featuresover-temperature protection and low-water cut-offensure reliable operation and safeguard both specimens and users.

FAQs of Accelerated Curing Tank:

Q: How does the Accelerated Curing Tank ensure uniform curing of concrete specimens?

A: The tank utilizes an integral water circulation pump to distribute heated water evenly throughout the chamber, ensuring all concrete specimens receive consistent temperature exposure during curing.Q: What are the benefits of using stainless steel for the inner chamber?

A: Stainless steel (SS304) provides excellent resistance to corrosion, maintains structural integrity under high temperatures, and facilitates easy cleaning for repeated industrial use.Q: When should the Accelerated Curing Tank be used in concrete testing?

A: This equipment is ideal for situations requiring accelerated strength testing of concrete cubes, such as quality control, research, and production environments where rapid test turnaround is essential.Q: Where is this curing tank typically installed and operated?

A: Designed for floor mounting, the tank is commonly installed in laboratories, industrial workshops, and quality assurance departments involved in concrete testing.Q: What safety features are included in the curing tank?

A: Key safety mechanisms include over-temperature protection, a low water level cut-off system, and a securely hinged stainless steel lid to minimize operational hazards.Q: How do you control and adjust the temperature during the curing process?

A: Temperature is governed by a digital controller, which displays real-time values on an LED or LCD screen. The operator can adjust the set point from ambient up to 100C, with a resolution of 0.1C for precise control.Q: What is the process for curing specimens using this tank?

A: Operators place concrete moulds (standard size 150 x 150 x 150 mm) into the tank, set the desired temperature and curing duration (1 hour to 99 hours) via the digital control panel, and monitor the process through the display. Safety systems activate if temperature or water level thresholds are breached.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Cement Testing Equipment Category

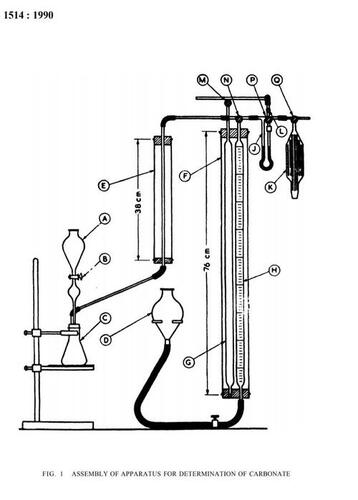

ASSEMBLY OF APPARATUS FOR DETERMINATION OF CARBONATE

Price 1.00 INR / Piece

Minimum Order Quantity : 1 , , Piece

Features : Leakproof Joints, Easy Assembly, Resistant to Acids

Product Type : Cement Testing

Usage : Determination of Carbonate content in Lime and Cement

Automation Grade : Manual

Waterbath for Soundness Test of Cement

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Features : Double walled, thermostatically controlled, removable rack, stainless steel inner chamber

Product Type : Waterbath for Soundness Test of Cement

Usage : Cement Testing Equipment

Automation Grade : SemiAutomatic

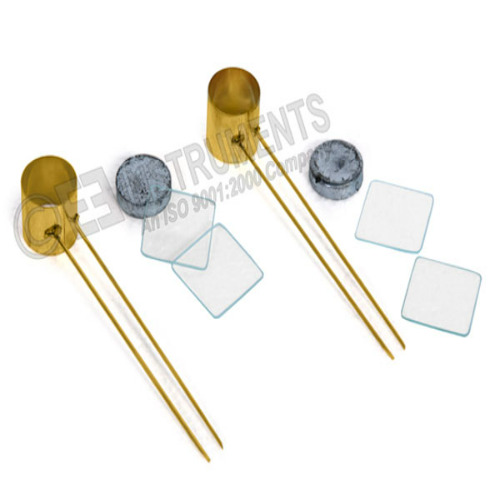

LE CHATLIER MOULD Set of Six

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Features : Made of brass with clamps and two indicator needles; corrosionresistant; rigid construction

Product Type : Le Chatlier Mould

Usage : Cement Testing Equipment

Automation Grade : Manual

Lab Ball Mill - Heavy Duty

Minimum Order Quantity : 1 Piece

Features : Accurate results, Robust construction, Efficient working

Product Type : Cement Testing

Usage : Laboratory

Automation Grade : Semi Automatic

|

EIE INSTRUMENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry