Waterbath for Soundness Test of Cement

Price 1.00 INR/ Piece

Waterbath for Soundness Test of Cement Specification

- Temperature

- Adjustable from ambient to 100C

- Frequency

- 50 Hz

- Measuring Range

- Ambient to boiling point

- Power Supply

- 230V AC, 50Hz

- Response Time

- Within 30 minutes to reach boiling

- Application

- To accommodate immersed Le-Chatelier moulds with specimens and to raise their temperature from (27 C 2 C) to boiling in (27 3 minutes).

- Equipment Type

- Waterbath for Soundness Test of Cement

- Display Type

- Analog/Digital (Model Dependent)

- Mounting Type

- Benchtop

- Max Height

- 375 mm (Depth)

- Usage

- Cement Testing Equipment

- Features

- Double walled, thermostatically controlled, removable rack, stainless steel inner chamber

- Specimen Size

- Standard Le-Chatelier mould

- Automation Grade

- Semi-Automatic

- Resolution

- 1C

- Number of Specimens

- 6 Le-Chatelier moulds

- Accuracy

- 1C

- Dimension (L*W*H)

- 550 X 365 X 375(L X W X D) mm Millimeter (mm)

- Operating Voltage

- 230V AC

- Interface Type

- Manual

- Product Type

- Waterbath for Soundness Test of Cement

- Capacity

- 6 moulds

- Machine Weight

- Approx. 18 kg

- Control Mode

- Through Thermostat

- Inner Chamber Material

- Stainless Steel

- Safety Features

- Overtemperature cut-off

- Insulation

- Glass Wool

- Outer Chamber Material

- Mild Steel, Powder Coated

- Heating Element

- Immersion type

- Drainage

- Drain outlet provided

- Dimensions (L*W*D)

- 550 x 365 x 375 mm

- Lid Type

- Removable perforated cover

Waterbath for Soundness Test of Cement Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 100 Pieces Per Month

- Delivery Time

- 4 Week

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Box / Corrugated Box

- Certifications

- ISO 9001 : 2015

About Waterbath for Soundness Test of Cement

Applications:

To accommodate immersed Le Chatelier moulds with specimens and to raise their temperature.

Optional accessories at extra cost:

Digital temperature controller with temperature sensor

Furtherdetails available on our website.

The Price mentioned here are subject to change as per the capacity,specifications and application of the user.

Purpose-Built for Le-Chatelier Soundness Testing

This waterbath is designed specifically for the soundness test of cement using Le-Chatelier moulds. It accommodates up to six specimens simultaneously, ensuring consistent testing conditions by raising their temperature efficiently from ambient to boiling point. The precision control and robust engineering make it suitable for frequent laboratory use.

Superior Construction and Safety Features

With a stainless steel inner chamber and a powder-coated mild steel exterior, the waterbath offers durability and longevity. Effective insulation using glass wool minimizes heat loss, while the overtemperature cut-off and drain outlet guarantee safe and user-friendly operation. The removable perforated cover facilitates easy specimen handling.

Ease of Use and Reliable Heating

The immersion-type heating element, paired with a thermostat, delivers rapid and uniform heatingreaching boiling within 30 minutes. Adjustable temperature and analog/digital display (depending on the model) offer flexibility. The bench-mounted semi-automatic design ensures it fits laboratory workflows seamlessly.

FAQs of Waterbath for Soundness Test of Cement:

Q: How does the waterbath for soundness test of cement operate?

A: This waterbath operates by immersing up to six Le-Chatelier moulds containing cement specimens and gradually increasing the temperature of the water from 27C (2C) to boiling (100C), maintaining accuracy within 1C using a thermostatically controlled immersion heater and insulated double-walled construction.Q: What materials are used for the inner and outer chambers of the waterbath?

A: The inner chamber is manufactured from stainless steel for corrosion resistance and easy cleaning, while the outer chamber consists of powder-coated mild steel, providing structural integrity and durability.Q: When should I use this waterbath in cement testing?

A: This waterbath is employed during the soundness testing phase of cement quality control, specifically when Le-Chatelier moulds are used to assess the expansion characteristics of cement samples. It ensures uniform and controlled heating as per the standard testing protocols.Q: Where is this equipment best utilized?

A: The waterbath is ideal for laboratories in cement manufacturing plants, construction material testing centers, and academic institutes where standardized cement soundness tests are regularly performed.Q: What is the process for testing soundness of cement with this waterbath?

A: To test cement soundness, place Le-Chatelier moulds with prepared specimens into the perforated removable rack inside the waterbath, set the desired temperature using the thermostat, and gradually heat from 27C to boiling according to standard requirements. The process is typically completed within 30 minutes.Q: How does the overtemperature cut-off function enhance safety?

A: The overtemperature cut-off feature automatically disconnects the power supply if the water temperature exceeds the preset limit, reducing the risk of overheating, equipment damage, or safety hazards.Q: What are the key benefits of using this waterbath for cement testing?

A: Core benefits include precise temperature control for reliable soundness results, ability to handle multiple specimens efficiently, robust safety features, durable stainless steel interior, and adaptability for various laboratory settings.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Cement Testing Equipment Category

Vicat Needle Apparatus for Gypsum

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : Vicat Needle Apparatus for Gypsum Test

Number of Specimens : Single specimen at a time (using one Vicat mould)

Automation Grade : Manual

Usage : Cement Testing Equipment

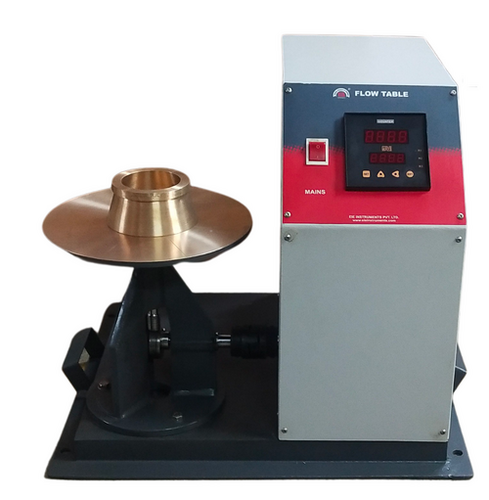

FLOW TABLE MOTORISED for Cement

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : Flow Table Motorized for Cement

Number of Specimens : One per operation

Automation Grade : Semiautomatic

Usage : Cement Testing Equipment

Southard Viscometer

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : Southard Viscometer

Number of Specimens : Single at a time

Automation Grade : Manual

Usage : Cement Testing Equipment

CEMENT MORTAR PERMEABILITY APPARATUS

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : Cement Mortar Permeability Apparatus

Number of Specimens : Three specimens per test

Automation Grade : Manual

Usage : Cement Testing Equipment

|

EIE INSTRUMENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry