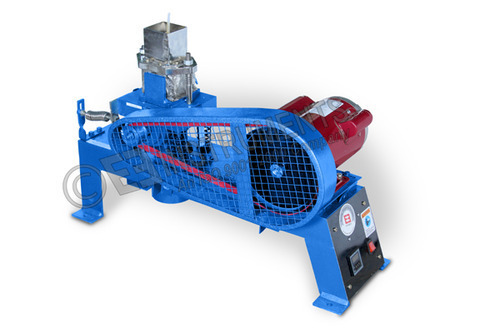

Vibrating Machine With Digital Timer and Mould

Vibrating Machine With Digital Timer and Mould Specification

- Usage

- Industrial

- Application

- A specially designed vibration machine is used for vibrating the mix in moulds at a frequency of 12000 400 cycles per minute, as per specifications.

- Weight

- 76 Kilograms (kg)

- Color

- Blue

- Dimension (L*W*H)

- 380 X 890 X 640 (L X W X D) mm Millimeter (mm)

- Operate Method

- Electric

- Product Type

- Vibrating Machine

- Features

- Accurate results, Robust construction, Efficient working

- Automation Grade

- Semi Automatic

- Machine Weight

- 76 Kilograms (kg)

Vibrating Machine With Digital Timer and Mould Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- Ahmedabad

- Supply Ability

- 100 Pieces Per Month

- Delivery Time

- 4 Week

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Box / Corrugated Box

- Main Export Market(s)

- Australia, Africa, Middle East, South America, Asia

- Main Domestic Market

- All India

- Certifications

- ISO 9001 : 2015

About Vibrating Machine With Digital Timer and Mould

Applications:

A specially designed vibration machine is used for vibrating the mix in moulds at a frequency specific per minute, as per specifications.

Construction Details:

- The vibrator is mounted over coiled spring to carry the cube mould and the vibrations are developed by means of a revolving eccentric shaft. By means of a balance weight beneath the base plate, attached rigidly to the frame, the centre of gravity of the whole machine, including the cube and mould, is brought either to the eccentric shaft or within a distance of 25 mm below it.

Furtherdetails available on our website.

The Price mentioned here are subject to change as per the capacity,specifications and application of the user.

Precision Vibration for Consistent Results

With its high frequency of 12,000 400 cycles per minute, this vibrating machine delivers uniform compaction across mixes in moulds. The digital timer allows users to accurately control operation cycles, ensuring every batch is processed to the same quality standard. This precision is crucial in producing durable, reliable samples in industrial settings.

Robust and Reliable Industrial Build

Engineered with an industrial-grade frame, the machines dimensions and 76 kg weight offer solid stability during use, reducing vibration-related error. The grey, corrosion-resistant finish extends the equipment lifecycle, making it suitable for demanding industrial environments such as construction material testing, laboratories, and manufacturing units.

FAQs of Vibrating Machine With Digital Timer and Mould:

Q: How does the vibrating machine with digital timer enhance mix compaction?

A: The vibrating machine uses a consistent frequency of 12,000 400 cycles per minute, combined with a digital timer, allowing users to precisely time the vibration process. This consistency ensures thorough and even compaction of mixes within the moulds, resulting in higher quality specimens.Q: What material types are suitable for this vibrating machine?

A: This machine is specifically designed for concrete or similar construction materials that need uniform compaction in moulds, making it ideal for both quality control and production environments.Q: When should the vibrating machine be used in the production process?

A: The machine should be used after the mould has been filled with the mix but before it has set. Vibration at this stage helps remove air pockets and ensures optimal density and homogeneity in the final product.Q: Where is the vibrating machine most commonly utilized?

A: It is predominantly used in industrial applications such as construction material testing laboratories, manufacturing plants, and quality control centers throughout India.Q: What is the process for operating the vibrating machine?

A: Place the filled mould onto the platform, set the desired vibration time using the digital timer, and activate the machine. The high-frequency vibration will compact the material uniformly before the mould is removed for further processing.Q: What are the main benefits of using this industrial vibrating machine?

A: Benefits include greater consistency and reliability in sample preparation, reduced human error, and compliance with industry standards, which together contribute to improved product quality and process efficiency.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Cement Testing Equipment Category

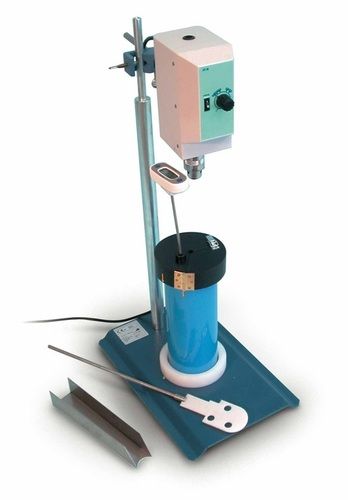

Southard Viscometer

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Features : Robust Construction, Corrosion Resistant Vessel, Easy Cleaning

Usage : Cement Testing Equipment

Application : The Southard viscosimeter shall be used for adjusting the consistency of the putty and a vessel of the shape and dimensions which shall be used for the determination of the volume yield.Â

Capacity : Approx. 500 ml vessel

Lime Reactivity Test Apparatus

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Features : Corrosionresistant construction, Easy to operate, Glass thermometric tube

Usage : Cement Testing Equipment

Application : Used for determining the reactivity on slaking of ground quicklime.

Capacity : Approx. 500 ml flask

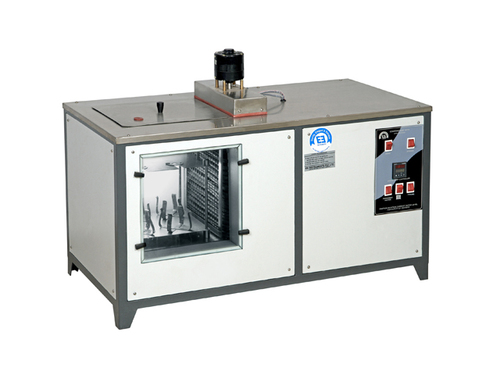

Constant Temperature Waterbath - For Specific Gravity Test Of Cement

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Features : Double walled construction, corrosion resistant, digital control, overtemperature protection, uniform temperature distribution

Usage : Cement Testing Equipment

Application : The water bath in general will fulfill the requirements of IS:4031 (Part 11) Method of Physical tests for hydraulic cement (Determination of Density)

Capacity : 8 Tests

Mortar Mixer

Minimum Order Quantity : 1 , , Piece

Features : Accurate results, Robust construction, Efficient working

Usage : For Cement Testing

Application : The instrument is specially designed to prepare cement mortar for Strength Determination.

Capacity : 05 liters, 10 liters Ltr

|

EIE INSTRUMENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry