UNCONFINED COMPRESSION TESTER WITH PROVING RING and DIAL GAUGE

Price 1.00 INR/ Piece

UNCONFINED COMPRESSION TESTER WITH PROVING RING and DIAL GAUGE Specification

- Display Type

- Dial gauge (mechanical analog)

- Usage

- Rock Testing Equipment

- Product Type

- UNCONFINED COMPRESSION TESTER FOR ROCK SAMPLES - WITH PROVING RING & DIAL GAUGE

- Application

- This equipment is used for determining unconfined compressive strength of intact rock core specimens.

- Max Height

- Approx. 450 mm

- Features

- Robust construction, portable, easy loading application, low maintenance

- Interface Type

- N/A (manual analog system)

- Power Supply

- Not required (manual)

- Specimen Size

- Typical: 38 mm diameter x 76 mm length (other sizes as per standards possible)

- Temperature

- Operating range: 10C to 50C

- Resolution

- 0.01 mm (dial gauge)

- Hardness

- High quality materials, machine-finished steel plates

- Equipment Type

- UNCONFINED COMPRESSION TESTER WITH PROVING RING AND DIAL GAUGE

- Frequency

- N/A (manual operation)

- Accuracy

- 1% of full scale

- Mounting Type

- Table top

- Test Range

- 0100 kN (with suitable proving ring)

- Number of Specimens

- Single specimen per test

- Measuring Range

- 0100 kN

- Automation Grade

- Manual

- Response Time

- Instantaneous (mechanical type)

- Humidity

- Up to 90% non-condensing (recommended to avoid corrosion)

- Operating Voltage

- Not applicable (manual system)

- Capacity

- Up to 100 kN (as per proving ring)

- Machine Weight

- Approx. 30 kg

- Test Speed

- 1.25 mm/min (manually operated)

- Test Width

- Compatible for standard core specimens (min 38 mm core diameter)

- Test Stroke

- 70 mm

- Control Mode

- Manual

- Accessories

- Supplied with base plate, upper and lower platens, loading yoke

- Loading Method

- Hand operated screw mechanism

- Core Clamping Mechanism

- Adjustable end platens with centering pins

- Travel Measurement

- Fine adjustment with vernier scale

- Proving Ring Capacity

- Supplied as per requirement (typically 30, 50, or 100 kN)

- Material Construction

- Corrosion resistant painted steel frame

- Deformation Measurement

- Dial Gauge Mounted on Loading Frame

- Load Measuring Device

- Calibrated Proving Ring with Dial Gauge Readout

UNCONFINED COMPRESSION TESTER WITH PROVING RING and DIAL GAUGE Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 100 Pieces Per Month

- Delivery Time

- 4 Week

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Box / Corrugated Box

- Certifications

- ISO 9001 : 2015

About UNCONFINED COMPRESSION TESTER WITH PROVING RING and DIAL GAUGE

Compliance Standards

ASTM D2938, IS 9143

Salient Features of load frame and its accessories

- The Load Frame is extremely versatile and designed to conduct Triaxial Unconfined test and Unconfined compression test on rock specimens with diameters from 38mm to 100mm and AX, BX, NX specimens.

- The Loading frame consists of a cabinet that houses the gear system and motor with sturdy angle iron frame.

- Loading is done through the bottom loading platen, which is carried on a lead screw that advances upwards.

- The top load bracket, which slides over two upright pillars, can be positioned at any desired height and locked. It carries a screw adaptor for standard Proving Rings or Load Cells.

- Load frame, 200 kn capacity 12 speed from 0.0064 to 1.25 mm per min

Furtherdetails available on our website.

The Price mentioned here are subject to change as per the capacity,specifications and application of the user.

Accurate Rock Strength Measurement

This tester offers meticulous assessment of unconfined compressive strength in rock cores. Its mechanical dial gauge and calibrated proving ring enable precise readings of force and deformation, making it an essential piece of equipment for geotechnical laboratories, research institutions, and field applications. Single specimen tests ensure consistency and reliability.

Robust and Portable Construction

Manufactured with high-quality, corrosion-resistant steel and finished machine plates, the device promises longevity and minimal maintenance. It is compact, portable, and mounts easily on a tabletop, enabling use in varied environments without electrical requirementsideal for remote fieldwork and in-situ testing.

User-Friendly Manual Operation

Equipped with a hand-operated screw mechanism, fine vernier adjustment, and easily interchangeable platens, the tester allows for convenient specimen loading and travel measurement. The analog dial gauge provides instantaneous readings, ensuring efficient workflows for rock analysis.

FAQs of UNCONFINED COMPRESSION TESTER WITH PROVING RING and DIAL GAUGE:

Q: How does the Unconfined Compression Tester measure rock core strength?

A: The tester measures rock core strength using a manually operated screw mechanism to apply load, a calibrated proving ring to quantify force, and a dial gauge to monitor specimen deformation. The precise load and displacement readings help determine unconfined compressive strength.Q: What specimen sizes are compatible with this tester?

A: This equipment is compatible with standard core specimens, typically measuring 38 mm in diameter and 76 mm in length. Other sizes can be tested as per industry standards and specific requirements.Q: When should I use this tester in my laboratory or field work?

A: This tester is ideal whenever you need to assess the unconfined compressive strength of intact rock samples, particularly in geotechnical investigations, site assessments, and academic research projects.Q: Where is the tester typically used and mounted?

A: The Unconfined Compression Tester is designed for both laboratory and field use. Its table-top mounting and portable construction make it suitable for workbenches and temporary field setups alike.Q: What is the process for operating the manual compression tester?

A: To operate, mount the specimen between the upper and lower platens, center using adjustable end platens and pins, then apply load using the hand screw. Observe load and deformation increments via the calibrated proving ring and dial gauge until specimen failure.Q: What are the benefits of using a manual, analog testing device?

A: Manual operation removes the need for electrical supply, ensuring portability and ease of use in remote locations. The robust mechanical components deliver high accuracy (1%) and instantaneous response, making maintenance and troubleshooting straightforward.Q: How is corrosion prevented given high humidity conditions?

A: The testers structure uses corrosion-resistant painted steel and is recommended for use in environments with humidity up to 90% non-condensing to extend its lifespan. Regular cleaning and proper storage further help avoid corrosion-related damage.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Civil Testing Instruments Category

TRIAXIAL TESTING MACHINE FOR ROCK

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : TRIAXIAL TESTING MACHINE FOR ROCK

Usage : Rock Testing Equipment

Automation Grade : Semi Automatic

Machine Weight : 765 Kilograms (kg)

Drilling Fluid Testing Equipment

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : Drilling Fluid Testing Equipment

Usage : Drilling Fluid Testing Equipment

Automation Grade : SemiAutomatic

Machine Weight : 32 kg

Solar Cell Testing Equipment

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : Solar Testing Equipment

Usage : Solar Testing Equipment

Automation Grade : Automatic

Machine Weight : approx. 120 kg

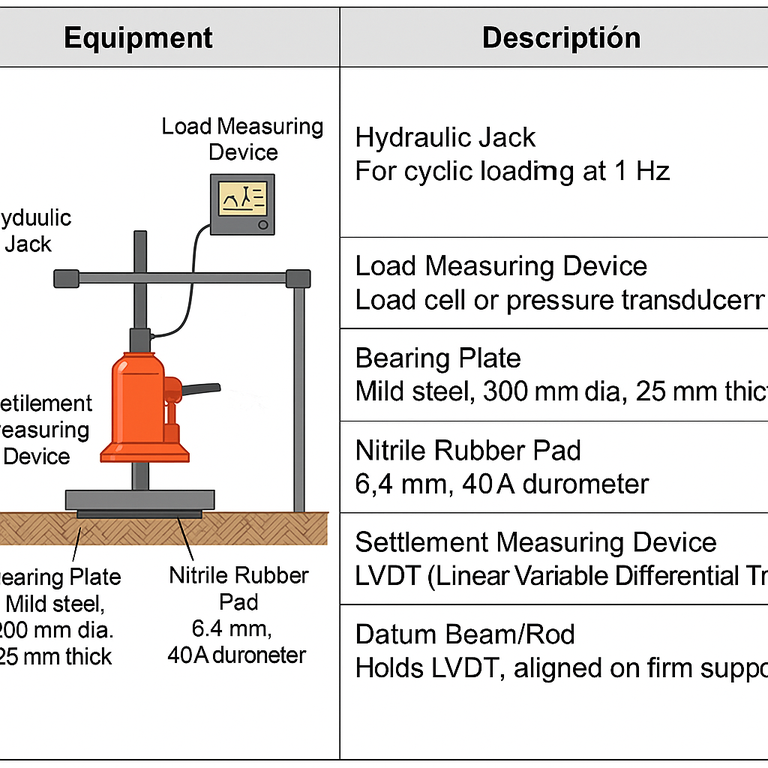

CYCLIC PLATE LOAD TEST

Minimum Order Quantity : 1 Piece

Product Type : CYCLIC PLATE LOAD TEST

Usage : GEOTEXTILE & GEOMEMBRANE TESTING INSTRUMENTS

Automation Grade : SemiAutomatic

Machine Weight : Approx. 150 kg

|

EIE INSTRUMENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry