TRIAXIAL TESTING MACHINE FOR ROCK

Price 1.00 INR/ Piece

TRIAXIAL TESTING MACHINE FOR ROCK Specification

- Port Size

- 1/8 inch NPT

- Accuracy

- 1%

- Specimen Size

- 38 mm, 50 mm diameter x 100 mm length

- Temperature

- 10C - 40C

- Dimension (L*W*H)

- 585 X 560 X 1420 (L X W X D) mm Millimeter (mm)

- Number of Specimens

- 1

- Humidity

- Up to 95% RH

- Resolution

- 0.001 MPa

- Test Range

- 0 - 100 kN

- Automation Grade

- Semi Automatic

- Max Height

- 1420 mm

- Interface Type

- RS232 / USB

- Weight

- 765 Kilograms (kg)

- Measuring Range

- 0.001 - 100 MPa

- Operating Voltage

- 220V

- Equipment Type

- TRIAXIAL TESTING MACHINE FOR ROCK

- Usage

- Rock Testing Equipment

- Response Time

- 2 s

- Gas Pressure

- 0-10 MPa

- Power Supply

- 220V AC, 50Hz

- Hardness

- Rock Specimen dependent

- Product Type

- TRIAXIAL TESTING MACHINE FOR ROCK

- Display Type

- Digital

- Mounting Type

- Floor Mounted

- Features

- Sturdy frame, User-friendly controls, Precision loading

- Application

- Rock Triaxial Compression Testing

- Frequency

- 50/60 Hz

- Capacity

- 100 kN

- Machine Weight

- 765 Kilograms (kg)

- Test Speed

- 0.01 - 5 mm/min

- Test Width

- 560 mm

- Test Stroke

- 100 mm

- Control Mode

- Automatic / Manual

- Compliance

- IS: 2720 (Part XII), ASTM D7012

- Pressure System

- High Pressure Cell with Pump

- Manufacturer Warranty

- 12 Months

- Oil Reservoir Capacity

- 5 Litres

- Load Application

- Hydraulic

- Main Frame Construction

- Heavy Duty Steel

- Safety Features

- Overload Protection

- Load Measurement

- Digital Indicator

- Load Cell Type

- Electronic Load Cell

TRIAXIAL TESTING MACHINE FOR ROCK Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 100 Pieces Per Month

- Delivery Time

- 4 Week

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Box / Corrugated Box

- Certifications

- ISO 9001 : 2015

About TRIAXIAL TESTING MACHINE FOR ROCK

It consists of following

(A) Automatic Compression Testing Machine with Touch Panel, Capacity 2000kN

(B) Hoek Type Triaxial Cell

(C) High pressure controller, Pressure Range 0.5 to 50 Mpa in steps of 0.5 Mpa

Compliance With Following International Standards:

EN 12390-4, ASTM C39, AASHTO T22, IS : 14858 (2000)

Precision Testing for Rock Strength Analysis

This TRIAXIAL TESTING MACHINE FOR ROCK delivers highly accurate results, thanks to its digital load measurement and electronic load cell. Its automated and manual controls ensure versatility for varied research and industrial testing needs. Constructed from durable steel, it withstands rigorous, repeated use while maintaining test reliability.

User-Friendly Design and Controls

With a straightforward digital display and intuitive interface, this triaxial testing machine simplifies complex testing procedures. The RS232/USB connectivity enables seamless data transfer, making it practical for modern laboratories keen on efficient data management and streamlined workflows.

Safety and Compliance Assured

The machine prioritizes operator safety through integrated overload protection and adheres to leading international standards (IS: 2720, ASTM D7012). This ensures confidence in both equipment durability and the reliability of your testing outcomes. A comprehensive 12-month manufacturer warranty further supports your investment.

FAQs of TRIAXIAL TESTING MACHINE FOR ROCK:

Q: How does the TRIAXIAL TESTING MACHINE FOR ROCK measure load during testing?

A: The machine uses an electronic load cell paired with a digital indicator to measure load accurately up to 100 kN. This ensures precise real-time load measurements during triaxial compression tests on rock specimens.Q: What are the key safety features of this triaxial testing machine?

A: The testing machine is equipped with overload protection, ensuring that loads beyond capacity do not damage the equipment or compromise user safety. Additionally, the high-quality steel construction provides stability during testing.Q: When is it suitable to use this triaxial testing machine?

A: This equipment is ideal for laboratory or field settings requiring evaluation of rock strength under triaxial stress, such as in civil engineering, mining, or geotechnical research. It operates effectively within a temperature range of 10C40C and can handle humid conditions up to 95% RH.Q: Where can the TRIAXIAL TESTING MACHINE FOR ROCK be installed?

A: The machine is floor mounted with dimensions 585 x 560 x 1420 mm, making it suitable for laboratory workspaces, research facilities, and testing centers. Its robust frame and moderate footprint allow installation in most industrial environments.Q: What is the process for conducting a test using this machine?

A: A rock specimen (38 mm or 50 mm in diameter, up to 100 mm length) is mounted in the high-pressure cell. The hydraulic system applies load at user-selected speeds (0.01 - 5 mm/min), which can be controlled automatically or manually. The digital system records measurements for analysis.Q: What are the main benefits of using this triaxial testing machine for rock analysis?

A: Key advantages include precise and repeatable test results, easy operation via digital controls, compliance with international standards, robust safety measures, and durable construction that withstands heavy usage.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Civil Testing Instruments Category

UNCONFINED COMPRESSION TESTER FOR ROCK DIGITAL MOTORIZED

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Rock Testing Equipment

Machine Weight : Approx. 85 kg

Features : Motorized loading, digital display, automatic data acquisition, limit switch protection

Application : Uniaxial compressive strength determination of rock samples

DIRECT SHEAR APPARATUS HAND OPERATED

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Rock Testing Equipment

Machine Weight : Approx. 38 kg

Features : Sturdy construction, removable shear box, high accuracy, compact manual device

Application : The equipment is used for Direct Shear Laboratory Test of Rock Samples. The test measures peak & residual Direct Shear Strength as a function of stress normal to the sheared plane. The equipment can be used for testing Core, Lump specimens.

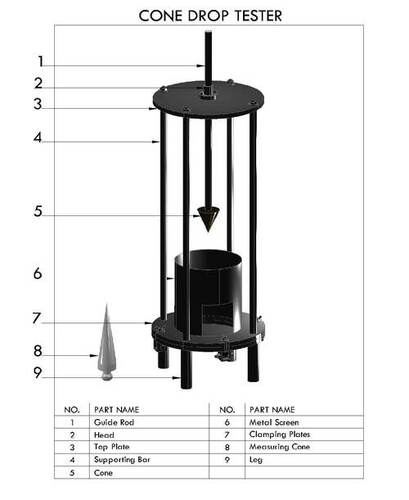

Cone Drop Tester

Price 1.00 INR / Number

Minimum Order Quantity : 1 Piece

Usage : Civil Engineering Testing Equipment

Machine Weight : Approx. 38 kg

Features : Robust frame, removable specimen holder, simple operation

Application : Mainly used to measure the puncture strength as well as the fabric quality to withstand aggregate penetration.

Load Truss

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Industrial Load Testing

Machine Weight : 150 kg (approx)

Features : Sturdy frame, modular design, overload protection

Application : Load bearing, structure testing, and material strength

|

EIE INSTRUMENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry