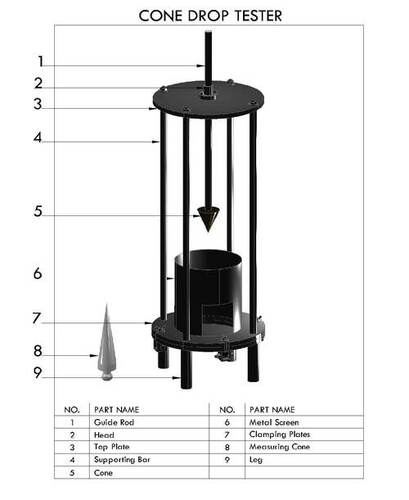

Cone Drop Tester

Price 1.00 INR/ Number

Cone Drop Tester Specification

- Usage

- Civil Engineering Testing Equipment

- Specimen Size

- 100 mm x 100 mm

- Product Type

- Cone Drop Tester FOR GEOSYNTHETIC (DYNAMIC PERFORATION TESTER)

- Display Type

- Scale (Manual)

- Hardness

- Cone tip: Hardened steel

- Features

- Robust frame, removable specimen holder, simple operation

- Temperature

- 10C to 40C

- Measuring Range

- Adjustable drop height up to 500 mm

- Number of Specimens

- Single

- Test Range

- Variable by drop height

- Application

- Mainly used to measure the puncture strength as well as the fabric quality to withstand aggregate penetration.

- Humidity

- Max. 80% (non-condensing)

- Resolution

- 1 mm

- Automation Grade

- Manual

- Power Supply

- Not Required (Manual)

- Frequency

- Single operation

- Max Height

- 500 mm

- Equipment Type

- Cone Drop Tester

- Mounting Type

- Floor standing

- Accuracy

- 1 mm drop height

- Response Time

- Instantaneous upon impact

- Machine Weight

- Approx. 38 kg

- Test Speed

- Standard free-fall acceleration (9.81 m/s)

- Test Width

- 100 mm

- Test Stroke

- Max. 500 mm

- Control Mode

- Manual

- Specimen Holder Material

- Aluminium

- Impact Energy

- 4.9 Joules

- Finish Type

- Scratch-resistant paint

- Test Cone Diameter

- 45 mm

- Test Cone Mass

- 1000 g

- Safety Features

- Safety locking mechanism, hand guard

- Frame Material

- Powder Coated Steel

- Dimensions (LxWxH)

- 210 x 210 x 1100 mm

- Fall Guide Type

- Precision vertical shaft

Cone Drop Tester Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 100 Pieces Per Month

- Delivery Time

- 4 Week

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Box / Corrugated Box

- Certifications

- ISO 9001 : 2015

About Cone Drop Tester

Application:

Mainly used to measure the puncture strength as well as the fabric quality to withstand aggregate penetration.

Details:

EIE Cone drop tester specifies a method to determine the resistance of Geosynthetics to penetration by a steel cone dropped from a fixed height. The degree of penetration is an indication of the behavior of the Geosynthetic, when sharp stones are dropped on its surface. The smaller the hole, the greater the resistance of geosynthetic OR geotextile to damage and vise versa.

The specimen is clamped between two steel rings. A steel cone is dropped from a height of 500 mm onto the center of the specimen. The degree of penetration is measured by insertion of a graduated cone into the hole. Graduated conical measure will be the part of standard supply.

Further details availableon our website.

The Price mentioned here are subject to change as per the capacity,specifications and application of the user.

Precision Impact Testing for Reliable Results

Engineered to deliver accurate and repeatable impact measurements, the Cone Drop Tester utilizes a precision vertical shaft and hardened steel cone. With adjustable drop height and 1 mm accuracy, civil engineers can confidently evaluate fabric resistance against penetration under standardized conditions.

Rugged Design and User Safety

The powder-coated steel frame and scratch-resistant finish provide lasting durability, while safety innovations such as a locking mechanism and hand guard protect operators during tests. The removable aluminium holder ensures easy specimen placement and removal, streamlining the workflow.

Manual Operation, No Power Needed

Designed for ease of use, the Cone Drop Tester operates manually, requiring no electrical power. This enables flexible deployment on-site or in laboratories, unrestricted by power availabilityideal for field testing or remote environments.

FAQs of Cone Drop Tester:

Q: How is the cone drop test performed using this equipment?

A: The test is conducted by securely placing a 100 mm x 100 mm specimen into the removable aluminium holder. The testers hardened steel cone (45 mm diameter, 1000 g) is manually released from a set height (up to 500 mm) via the precision vertical shaft, allowing it to impact the specimen with a defined energy. The drop height is measured with a manual scale, ensuring consistent results.Q: What materials or fabrics can be evaluated using the Cone Drop Tester?

A: This tester is primarily designed for assessing the puncture strength and quality of fabric or geo-materials used in civil engineering, such as geotextiles and membranes. Its variable drop height and robust construction accommodate a range of materials requiring aggregate penetration resistance testing.Q: When should the Cone Drop Tester be used?

A: The Cone Drop Tester is ideal for use both in laboratory environments and on construction sites, especially when evaluating new materials or verifying quality standards before installation. Use it when material performance against puncture or penetration by aggregates needs verification.Q: Where is the Cone Drop Tester typically installed or used?

A: This floor-standing unit is suitable for civil engineering testing laboratories, research institutions, or directly on-site at construction locations where fabric quality or performance must be assessed. Its manual operation means no dependency on external power sources.Q: What is the process for adjusting the test parameters?

A: Users can manually set the drop height up to 500 mm with 1 mm resolution using the vertical scale. The single specimen holder is designed for rapid loading and unloading, while the cone mass and diameter remain fixed for standardized testing.Q: How does the Cone Drop Tester enhance safety during operation?

A: The integrated safety locking mechanism prevents accidental drop triggering during specimen placement. Additionally, the hand guard keeps operators hands away from the impact zone, reducing the risk of injury during each test cycle.Q: What are the benefits of using a manual Cone Drop Tester?

A: Manual operation offers unmatched simplicity and reliability, with no need for electrical power. The sturdy construction, precise measurement capabilities, and straightforward specimen handling make it a cost-effective and dependable tool for civil engineering applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Civil Testing Instruments Category

TRIAXIAL TESTING MACHINE FOR ROCK

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Automation Grade : Semi Automatic

Machine Weight : 765 Kilograms (kg)

Usage : Rock Testing Equipment

Product Type : TRIAXIAL TESTING MACHINE FOR ROCK

GRADIENT RATIO TEST APPARATUS

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Automation Grade : Semiautomatic/manual

Machine Weight : Approx. 24 kg

Usage : Geotextile & Soil Permeability Test

Product Type : Gradient Ratio Test Apparatus

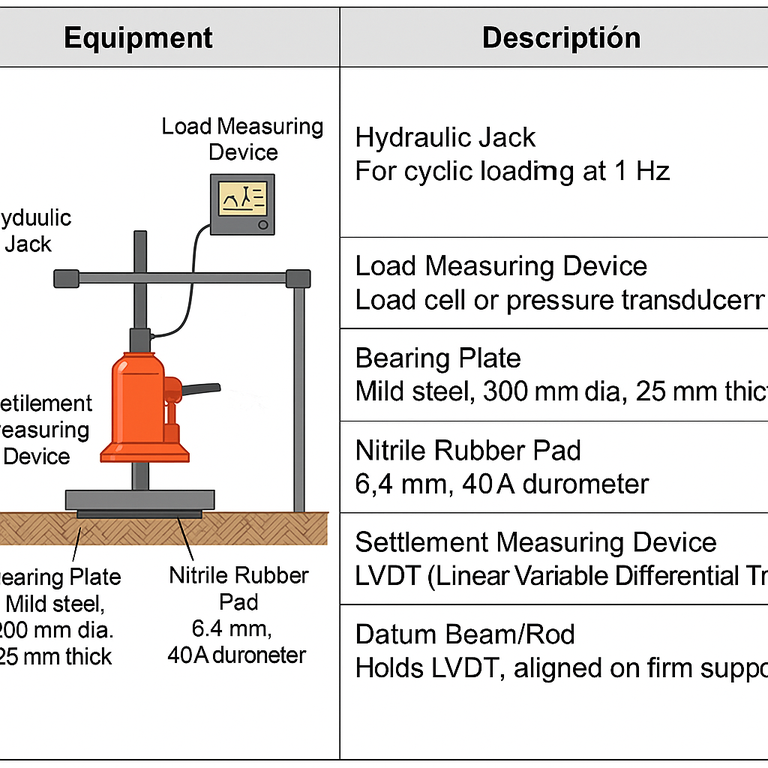

CYCLIC PLATE LOAD TEST

Minimum Order Quantity : 1 Piece

Automation Grade : SemiAutomatic

Machine Weight : Approx. 150 kg

Usage : GEOTEXTILE & GEOMEMBRANE TESTING INSTRUMENTS

Product Type : CYCLIC PLATE LOAD TEST

Ductility Mould

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Automation Grade : Manual

Machine Weight : Approx. 1.5 kg

Usage : Spares and Accessories

Product Type : Ductility Mould

|

EIE INSTRUMENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry