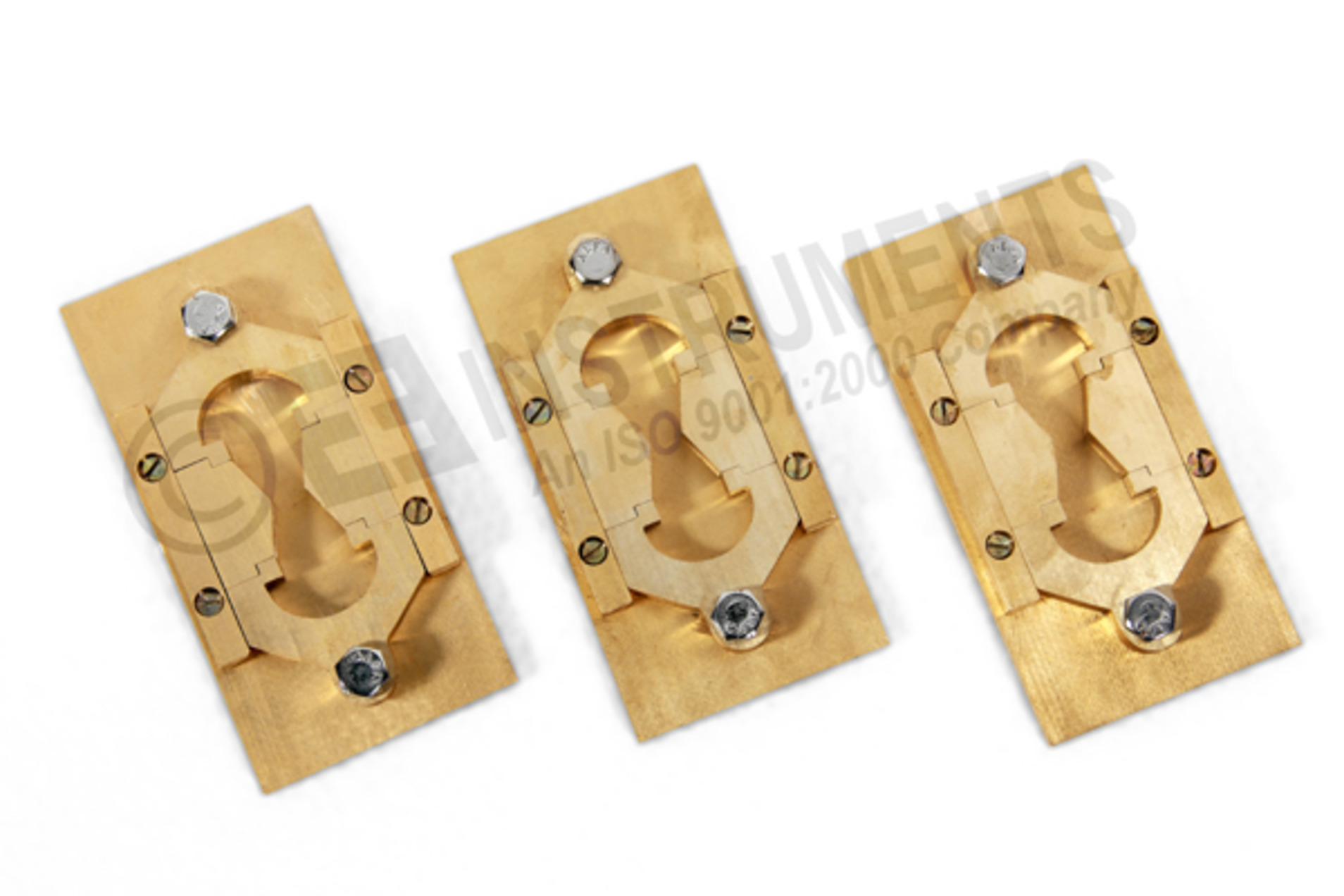

Ductility Mould

Price 1.00 INR/ Piece

Ductility Mould Specification

- Features

- Corrosion resistant, precision engineered mould cavities

- Equipment Type

- Testing Mould

- Usage

- Spares and Accessories

- Number of Specimens

- 3 at a time

- Specimen Size

- Mould cavity 30 mm x 20 mm x 75 mm

- Temperature

- Ambient or as per test requirement

- Mounting Type

- Bench mounted

- Test Range

- Up to 75 cm elongation

- Product Type

- Ductility Mould

- Application

- Bitumen Ductility Test

- Measuring Range

- Up to 75 cm elongation

- Accuracy

- As per IS 1208

- Hardness

- High strength brass/steel construction

- Humidity

- Ambient

- Automation Grade

- Manual

- Capacity

- 3 specimens

- Machine Weight

- Approx. 1.5 kg

- Test Width

- Mould width 20 mm

- Control Mode

- Manual

- Packing Type

- Wooden box or as specified

- Mould Cavity Dimensions

- 30 mm x 20 mm x 75 mm

- Compatible Equipment

- Ductility Testing Machine

- Material

- Brass/Steel

- Cleaning Method

- Easily detachable for cleaning

- Number of Parts

- 3 part mould (Base, Sides, Brass plate)

- Standards

- IS 1208:1978, ASTM D113

- Finish

- Machined with smooth cavity surface

Ductility Mould Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 500 Pieces Per Month

- Delivery Time

- 4 Week

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Box / Corrugated Box

- Certifications

- ISO 9001 : 2015

About Ductility Mould

Construction Details:

Made of brass/Gunmetal with the shape, dimensions and tolerances as shown. The ends b and b are known as clips, and the parts as sides of the mould

Furtherdetails available on our website.

The Price mentioned here are subject to change as per the capacity,specifications and application of the user.

Precision-Engineered for Accurate Testing

Manufactured from robust brass or steel, the Ductility Mould offers a smooth, precisely machined cavity. It enables highly accurate measurement of the ductility of bituminous materials, a critical parameter in road construction and maintenance quality checks. Certified by IS and ASTM standards, it stands out for its uniform test conditions and repeatable results.

User-Friendly and Easy Maintenance

The three-part design allows effortless assembly and quick disassembly for thorough cleaning, ensuring the integrity of each test. Its corrosion-resistant build and manual operation mean minimal wear and low maintenance, providing reliable service in high-throughput laboratory environments and field labs alike.

FAQs of Ductility Mould:

Q: How is the ductility mould used in bitumen testing?

A: The ductility mould is used to shape and hold bitumen samples for ductility tests, following IS 1208:1978 or ASTM D113. The specimen, formed in the mould, is elongated in a ductility testing machine to measure how far it stretches before breaking, which assesses the flexibility of paving materials.Q: What are the benefits of the three-part brass/steel construction?

A: The three-part mouldconsisting of a base, sides, and brass plateoffers easy detachment for cleaning, excellent durability, and precise cavity formation. Brass or steel construction further provides high strength and corrosion resistance, resulting in consistent and reliable test performance.Q: Where can this mould be mounted and used?

A: With a bench-mounting configuration, the mould is suitable for use in laboratory settings, research facilities, and construction material testing sites. Its robust build accommodates both field and indoor testing environments across India.Q: What cleaning method is recommended for this ductility mould?

A: The moulds design ensures it is easily detachable, allowing straightforward removal of residues. Simply disassemble the base, sides, and brass plate after use, then clean each part individually using standard laboratory cleaning practices to maintain the smooth cavity surface.Q: When should the ductility mould be used during road material testing?

A: This mould should be used whenever testing the ductility of bituminous binders is required to evaluate their suitability for flexible pavements, ensuring the asphalt complies with relevant IS or ASTM standards prior to construction or maintenance.Q: What is the maximum elongation that can be tested with this mould?

A: The mould, in conjunction with compatible ductility testing machines, supports measurement of specimen elongation up to 75 cm, in compliance with IS 1208:1978 and ASTM D113 standards.Q: How many specimens can be tested simultaneously with this mould?

A: Designed for efficiency, the mould cavity allows the preparation and testing of up to three specimens at once, optimizing laboratory throughput and ensuring consistent comparative results.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Civil Testing Instruments Category

ABRASION RESISTANCE TESTING MACHINE FOR GEOTEXTILE

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Frequency : 50 Hz

Features : Robust construction, adjustable test parameters, digital counter

Automation Grade : SemiAutomatic

Usage : Civil Engineering Testing Equipment

Drilling Fluid Testing Equipment

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Frequency : 50 Hz

Features : Corrosionresistant, portable design, easy calibration, multipurpose

Automation Grade : SemiAutomatic

Usage : Drilling Fluid Testing Equipment

UNCONFINED COMPRESSION TESTER FOR ROCK DIGITAL MOTORIZED

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Frequency : 50 Hz

Features : Motorized loading, digital display, automatic data acquisition, limit switch protection

Automation Grade : Automatic / Motorized

Usage : Rock Testing Equipment

Solar Cell Testing Equipment

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Frequency : 50 Hz

Features : High Precision Measurement, RealTime Monitoring, Data Storage

Automation Grade : Automatic

Usage : Solar Testing Equipment

|

EIE INSTRUMENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry