CYCLIC PLATE LOAD TEST

CYCLIC PLATE LOAD TEST Specification

- Usage

- GEOTEXTILE & GEOMEMBRANE TESTING INSTRUMENTS

- Humidity

- 85% RH (Non-condensing)

- Test Range

- 0-500 kN

- Product Type

- CYCLIC PLATE LOAD TEST

- Operating Voltage

- 220V AC

- Classification

- GEOTEXTILE & GEOMEMBRANE TESTING INSTRUMENTS

- Number of Specimens

- Single / Multiple

- Measuring Range

- 0-500 kN

- Frequency

- 50 Hz

- Application

- GEOTEXTILE & GEOMEMBRANE TESTING INSTRUMENTS

- Interface Type

- RS232 / USB (Optional)

- Accuracy

- 1%

- Resolution

- 0.01 kN

- Automation Grade

- Semi-Automatic

- Hardness

- As per IS standard

- Gas Pressure

- Ambient

- Specimen Size

- 300 mm dia. or as per requirement

- Power Supply

- 220V/50Hz AC

- Max Height

- 800 mm

- Equipment Type

- Cyclic Plate Load Test Apparatus

- Display Type

- Digital Display

- Temperature

- 10C to 40C

- Response Time

- <2 sec

- Mounting Type

- Floor Mounted

- Features

- Sturdy Construction, Precise Measurement, Portable

- Port Size

- Standard 25 mm

- Capacity

- 500 kN

- Machine Weight

- Approx. 150 kg

- Test Speed

- 0.1-20 mm/min adjustable

- Test Width

- Up to 300 mm

- Test Stroke

- 0-100 mm

- Control Mode

- Automatic / Manual

- Hydraulic Jack

- Included with Hand Pump

- Finish

- Anti-corrosive powder coated

- Plate Material

- High-grade Steel

- Transportability

- Wheel-mounted unit

- Weight Approximation

- 150 kg (without accessories)

- Recording System

- Microprocessor based Data Logger

- Safety Feature

- Overload Protection

- Load Cell Type

- Precision Strain Gauge Type

CYCLIC PLATE LOAD TEST Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 5 Pieces Per Month

- Packaging Details

- Wooden Box / Corrugated Box

About CYCLIC PLATE LOAD TEST

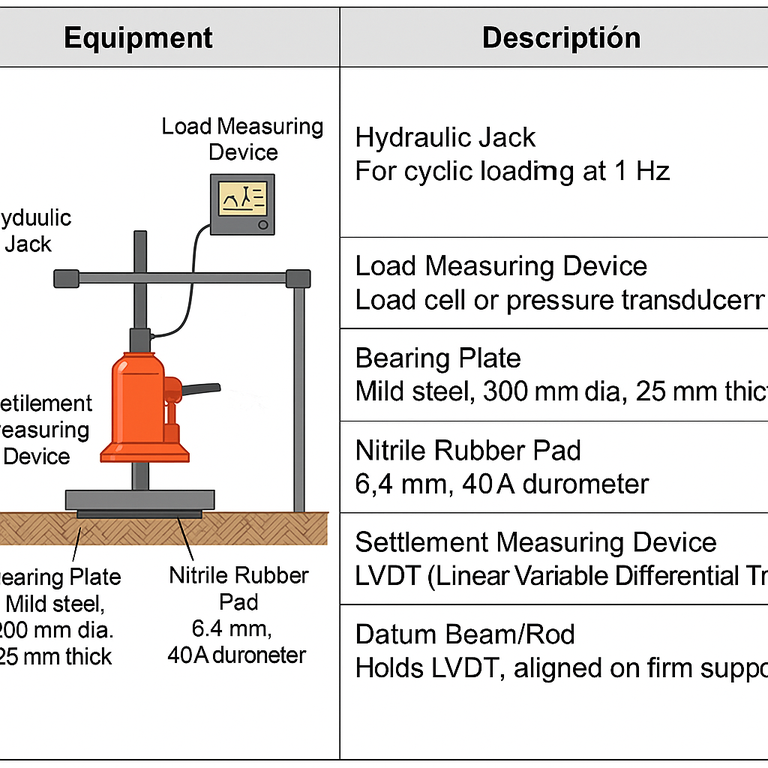

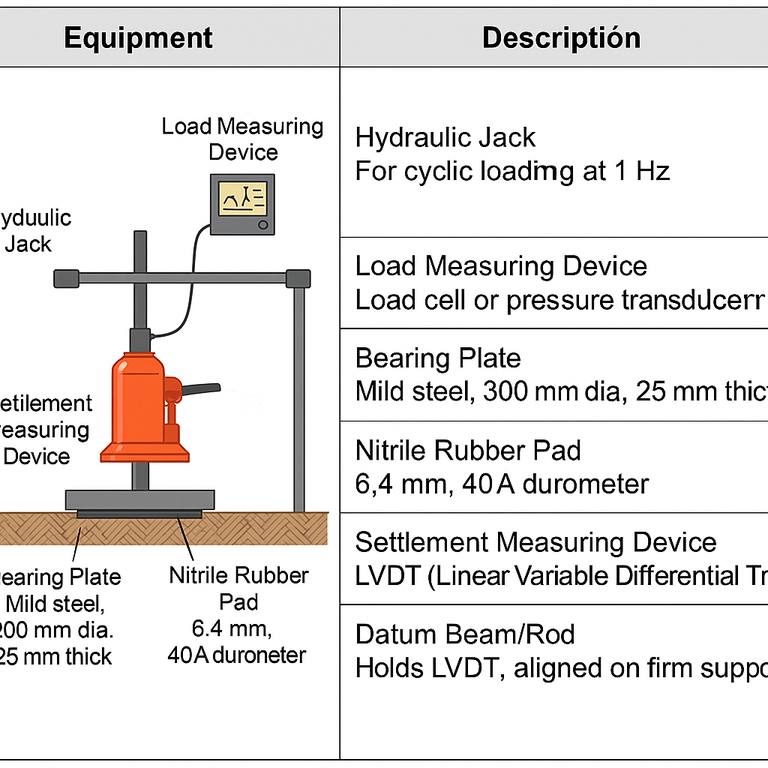

The Cyclic Plate Load Test (CPLT) is a field performance test designed to assess the structural performance and improvement due to geosynthetic reinforcement in pavement layers.

Further details available on our website.

Price and specifications mentioned here are subject to change as per theapplication, customer requirements and prevailing market conditions. Pleaserefer to us for the final rates and offer.

Advanced Load Measurement and Data Logging

This apparatus integrates a precision strain gauge type load cell for accurate force measurement and a microprocessor-based data logger to reliably record test data. The high-resolution digital display ensures clear readouts, while the fast response time (<2 sec) supports real-time monitoring during critical testing phases.

Robust, Portable, and Safe Construction

Engineered from high-grade steel and finished with anti-corrosive powder coating, the device is designed for rugged field use and offers ease of mobility due to its wheel-mounted configuration. The built-in overload protection feature enhances operational safety, and the sturdy construction adheres to IS standard hardness for consistent performance.

Versatile Applications and Adjustable Features

Ideal for geotextile and geomembrane testing, the cyclic plate load test apparatus accommodates a wide range of specimen sizes and types. Its adjustable control modes (automatic/manual) and flexible parameters, such as test speed and width, address diverse testing requirements. The equipment is suitable for exporters, service providers, manufacturers, suppliers, and traders in geotechnical domains.

FAQs of CYCLIC PLATE LOAD TEST:

Q: How is the cyclic plate load test performed using this apparatus?

A: The test is performed by placing the steel test plate on a prepared surface, applying load through the hydraulic jack, and recording data with a microprocessor-based logger. Load is increased cyclically, while displacement is monitored using the digital display. The process can be managed manually or automatically, ensuring precise, repeatable results.Q: What are the benefits of the precision strain gauge load cell in this equipment?

A: The precision strain gauge load cell provides high accuracy (1%) and fine resolution (0.01 kN), ensuring reliable measurements throughout the test. This accuracy is critical for obtaining consistent and trustworthy results in geotechnical investigations, supporting reliable engineering decisions.Q: When should I use the cyclic plate load test apparatus?

A: This apparatus is used primarily in geotextile and geomembrane testing projects, whenever there is a need to evaluate bearing capacity, settlement, and performance characteristics of soil or subgrade materials, particularly before construction or infrastructure projects.Q: Where can this equipment be deployed for testing?

A: The wheel-mounted, portable design allows deployment both in laboratories and field test sites. Its robust, anti-corrosive construction ensures reliable performance in diverse environmental conditions across varied geotechnical projects.Q: What is the process for setting up the cyclic plate load test apparatus?

A: To set up the apparatus, position the steel plate on the test area, connect the hydraulic jack and hand pump, and interface the load cell with the digital data logger. Adjust test parameters using easy-to-access controls, and initiate data acquisition. The process is streamlined, requiring minimal tools and straightforward calibration.Q: How does the overload protection feature enhance safety?

A: The integrated overload protection system automatically limits loads beyond safe operating thresholds, safeguarding both the equipment and operator from accidental overloading and potential mechanical failure during testing.Q: What advantages does the microprocessor-based data logger offer?

A: The microprocessor-based data logger enables automated, high-speed data collection with digital accuracy. It supports real-time analysis and offers convenient PC connectivity through an optional RS232 or USB interface, ensuring data can be stored, transferred, and analyzed efficiently.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Civil Testing Instruments Category

TRIAXIAL TESTING MACHINE FOR ROCK

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Rock Testing Equipment

Automation Grade : Semi Automatic

Application : Rock Triaxial Compression Testing

Features : Sturdy frame, Userfriendly controls, Precision loading

Solar Cell Testing Equipment

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Solar Testing Equipment

Automation Grade : Automatic

Application : Solar Module, Solar Cell Performance Analysis

Features : High Precision Measurement, RealTime Monitoring, Data Storage

UNCONFINED COMPRESSION TESTER WITH PROVING RING and DIAL GAUGE

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Rock Testing Equipment

Automation Grade : Manual

Application : This equipment is used for determining unconfined compressive strength of intact rock core specimens.

Features : Robust construction, portable, easy loading application, low maintenance

DIRECT SHEAR APPARATUS HAND OPERATED

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Rock Testing Equipment

Automation Grade : Manual

Application : The equipment is used for Direct Shear Laboratory Test of Rock Samples. The test measures peak & residual Direct Shear Strength as a function of stress normal to the sheared plane. The equipment can be used for testing Core, Lump specimens.

Features : Sturdy construction, removable shear box, high accuracy, compact manual device

|

EIE INSTRUMENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry