UNCONFINED COMPRESSION TESTER FOR ROCK DIGITAL MOTORIZED

Price 1.00 INR/ Piece

UNCONFINED COMPRESSION TESTER FOR ROCK DIGITAL MOTORIZED Specification

- Number of Specimens

- 1 at a time

- Resolution

- 0.01 kN

- Application

- Uniaxial compressive strength determination of rock samples

- Measuring Range

- 0 - 100 kN

- Specimen Size

- 38 mm diameter x 76 mm height (Standard), other sizes optional

- Accuracy

- 1% of indicated value

- Power Supply

- 230V AC, 50 Hz

- Max Height

- 500 mm

- Test Range

- 0 to 100 kN

- Equipment Type

- UNCONFINED COMPRESSION TESTER FOR ROCK - DIGITAL MOTORIZED

- Temperature

- Operating: 10C to 45C

- Product Type

- UNCONFINED COMPRESSION TESTER FOR ROCK - DIGITAL MOTORIZED

- Automation Grade

- Automatic / Motorized

- Humidity

- Up to 85% RH, non-condensing

- Frequency

- 50 Hz

- Features

- Motorized loading, digital display, automatic data acquisition, limit switch protection

- Mounting Type

- Table Top

- Port Size

- Standard 1/4 BSP

- Interface Type

- RS232 / USB

- Operating Voltage

- 230V AC 10%

- Hardness

- For hard and soft rock testing

- Display Type

- Digital LED

- Usage

- Rock Testing Equipment

- Response Time

- <1 Sec

- Capacity

- 100 kN maximum

- Machine Weight

- Approx. 85 kg

- Test Speed

- 0.5 to 5 mm/min (adjustable)

- Test Width

- 250 mm

- Test Stroke

- 50 mm

- Control Mode

- Digital Motorized with Microprocessor control

- Finish

- Corrosion-resistant enamel

- Ambient Conditions

- Well-ventilated area, dust free

- Motor Type

- Stepper/Servo motor

- Platen Size

- 100 mm diameter

- Calibration

- Supplied with calibration certificate traceable to NABL

- Ram Travel

- Up to 50 mm

- Frame Construction

- Rigid mild steel with powder coating

- Safety

- Emergency stop and overload protection

- Data Output

- PC connectivity for report generation

UNCONFINED COMPRESSION TESTER FOR ROCK DIGITAL MOTORIZED Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 100 Pieces Per Month

- Delivery Time

- 4 Week

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Box / Corrugated Box

- Certifications

- ISO 9001 : 2015

About UNCONFINED COMPRESSION TESTER FOR ROCK DIGITAL MOTORIZED

This equipment is used for determining unconfined compressive strength of intact rock core specimens. The rock sample is cut to length and the ends are machined flat. The specimen is placed in a loading frame and if required heated to the desired test temperature. Axial load is continuously increased on the specimen unit peak load and failure are obtained.

The Load Frame is extremely versatile and designed to conduct Unconfined compression test on rock specimens with diameters from 38mm to 100mm and AX, BX, NX specimens.

The Loading frame consists of a cabinet that houses the gear system and motor with sturdy angle iron frame. Loading is done through the bottom loading platen, which is carried on a lead screw that advances upwards. The top load bracket, which slides over two upright pillars, can be positioned at any desired height and locked. It carries a screw adaptor for standard Proving Rings or Load Cells.

Furtherdetails available on our website.

The Price mentioned here are subject to change as per the capacity,specifications and application of the user.

Advanced Digital Control and Safety

The Digital Motorized Unconfined Compression Tester integrates microprocessor-based control and automatic motorized operation, allowing precise adjustments and repeatability in test procedures. Safety features, including emergency stop, overload protection, and limit switch protection, ensure safe working conditions during tests. The rigid construction and corrosion-resistant finish enhance durability, making it suitable for long-term laboratory use.

Comprehensive Data Management

With integrated digital LED display and PC connectivity via RS232 or USB, users can generate, archive, and print comprehensive test reports. Calibration is provided with an NABL-traceable certificate for assured accuracy. Automatic data acquisition streamlines the testing workflow, and the system delivers high measurement accuracy (1% of indicated value) and rapid response time (<1 second).

Optimized for Laboratory Conditions

Built for stability in well-ventilated, dust-free environments, this tester accommodates ambient temperatures from 10C to 45C and up to 85% non-condensing humidity. The robust, table-top design makes installation effortless, and the adjustable platen and ram travel support varied rock sample types, including both hard and soft specimens. Its 100 kN capacity ensures suitability for a wide range of uniaxial compressive strength applications.

FAQs of UNCONFINED COMPRESSION TESTER FOR ROCK DIGITAL MOTORIZED:

Q: How does the digital motorized control benefit the rock compression test process?

A: The digital motorized control ensures precise, consistent loading during testing, reducing operator error and enhancing the repeatability of results. Microprocessor-based automation enables easy adjustments of test parameters, streamlining the entire process and allowing for rapid, reliable data acquisition.Q: What is the standard specimen size supported by this unconfined compression tester?

A: The tester is designed to accommodate rock specimens measuring 38 mm in diameter and 76 mm in height as standard, though it can be configured for other sizes upon request to suit varied testing requirements.Q: When should calibration be performed and how is accuracy ensured?

A: Each unit is supplied with a calibration certificate traceable to NABL for immediate use. Periodic recalibration is recommended according to laboratory protocols, especially before critical testing sequences, to maintain the devices high accuracy of 1% of indicated value.Q: Where is the optimal environment to operate this equipment?

A: Operation is recommended in a well-ventilated, dust-free laboratory area, within a temperature range of 10C to 45C and humidity up to 85% RH, non-condensing. Such conditions preserve equipment integrity and ensure precise measurements.Q: What is the general process for conducting a test with this machine?

A: After placing a properly prepared rock specimen between the machines platens, the operator selects desired test parameters on the digital interface. The automated system applies force until failure, collects measurements digitally, and enables data transfer to a PC for report generation.Q: How does the integrated safety system enhance laboratory usage?

A: Safety features such as emergency stop, overload protection, and limit switches prevent accidents and equipment damage during testing, ensuring safe operation for users even during high-capacity or long-duration tests.Q: What are the main benefits of using this digital unconfined compression tester for rock analysis?

A: This equipment provides highly accurate, automated, and efficient measurement of rock strength with minimal operator intervention. The digital interface, PC connectivity, and robust safety mechanisms combine to deliver reliable results, improving laboratory productivity and data management capabilities.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Civil Testing Instruments Category

TRIAXIAL TESTING MACHINE FOR ROCK

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Features : Sturdy frame, Userfriendly controls, Precision loading

Usage : Rock Testing Equipment

Control Mode : Automatic / Manual

Application : Rock Triaxial Compression Testing

ABRASION RESISTANCE TESTING MACHINE FOR GEOTEXTILE

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Features : Robust construction, adjustable test parameters, digital counter

Usage : Civil Engineering Testing Equipment

Control Mode : Digital/Manual

Application : Geotextile Abrasion Resistance Tester is used to determine the resistance of geotextile or geotextilerelated products to abrasion using an abrasion tester by Sand Paper/Sliding Block Method

UNCONFINED COMPRESSION TESTER WITH PROVING RING and DIAL GAUGE

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Features : Robust construction, portable, easy loading application, low maintenance

Usage : Rock Testing Equipment

Control Mode : Manual

Application : This equipment is used for determining unconfined compressive strength of intact rock core specimens.

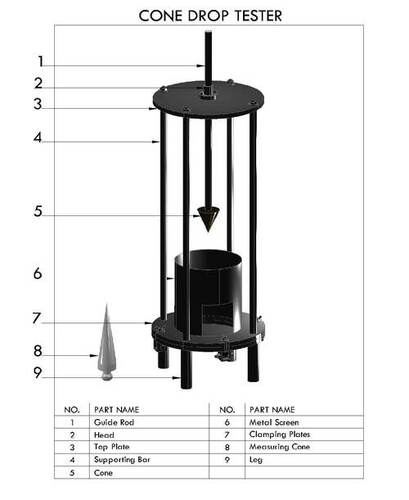

Cone Drop Tester

Price 1.00 INR / Number

Minimum Order Quantity : 1 Piece

Features : Robust frame, removable specimen holder, simple operation

Usage : Civil Engineering Testing Equipment

Control Mode : Manual

Application : Mainly used to measure the puncture strength as well as the fabric quality to withstand aggregate penetration.

|

EIE INSTRUMENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry