ASPHALT MIXER-THEORETICAL DENSITY METER-WITH VACUUM PUMP

Price 1.00 INR/ Piece

ASPHALT MIXER-THEORETICAL DENSITY METER-WITH VACUUM PUMP Specification

- Specimen Size

- Typically 1000-4000 g asphalt mix

- Frequency

- 50 Hz

- Resolution

- 0.001 g/cm

- Port Size

- Suction port 6 mm

- Automation Grade

- Semi-automatic

- Measuring Range

- 0.900 2.500 g/cm

- Number of Specimens

- One (1) per test

- Test Range

- 0-100% Theoretical Maximum Specific Gravity (Rice Test)

- Equipment Type

- Theoretical Density Meter with Mixer & Vacuum

- Response Time

- Within 60 seconds

- Operating Voltage

- 230V AC

- Interface Type

- Manual/Analog

- Accuracy

- 0.01 g/cm

- Gas Pressure

- Vacuum up to 13.3 kPa (100 mm Hg)

- Temperature

- 10C to 40C operating

- Humidity

- Max. 85% RH

- Mounting Type

- Bench-top

- Application

- Measurement of theoretical maximum specific gravity of asphalt mixtures

- Display Type

- Analog/Vacuum gauge

- Max Height

- Approx. 370 mm

- Power Supply

- 230V AC, 50 Hz

- Features

- Integrated vacuum pump, Desiccator included, Clear viewing chamber, Removable vacuum gauge

- Usage

- Civil Engineering, Road Construction Quality Control

- Capacity

- 5 liters (flask capacity)

- Machine Weight

- Approx. 18 kg

- Test Speed

- Standard vacuum rate 1 kPa/sec

- Control Mode

- Manual/Automatic

- Vacuum Pump Type

- Oil-sealed rotary/vane vacuum pump

- Vacuum Control

- Fine adjustment with manual valve

- Flask Material

- Heavy-duty borosilicate glass

- Chamber Material

- High-grade polycarbonate and corrosion-resistant metal

- Included Accessories

- Desiccator, Vacuum hoses, Release valve

- Safety Mechanism

- Overload protection for vacuum pump

- Noise Level

- <65 dB(A)

- Gasket Material

- Chemical-resistant rubber

- Compliance Standard

- ASTM D2041 / AASHTO T209

ASPHALT MIXER-THEORETICAL DENSITY METER-WITH VACUUM PUMP Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 50 Pieces Per Year

- Delivery Time

- 4 Week

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Box / Corrugated Box

- Certifications

- ISO 9001 : 2001

About ASPHALT MIXER-THEORETICAL DENSITY METER-WITH VACUUM PUMP

Applications

This equipment is used for determination of theoretical density of asphalt mixer by vacuum method for application such as asphalt mixer design, road condition investigation, calculation of porosity and compactness in road construction quality management.

Furtherdetails available on our website.

Price and specificationsmentioned here are subject to change as per the application, customerrequirements and prevailing market conditions. Please refer to us for the finalrates and offer.

Precision in Asphalt Testing

This density meter ensures meticulous measurement with an accuracy of 0.01 g/cm and a resolution of 0.001 g/cm. Ideal for obtaining the theoretical maximum specific gravity of asphalt, it supports specimen sizes between 10004000 g and features a standard 5-liter flask capacity. This optimal precision directly supports quality control in pavement construction.

Durable and User-Friendly Construction

Crafted from corrosion-resistant metals and high-grade polycarbonate, the device withstands rigorous laboratory use. Heavy-duty borosilicate glass flasks and chemical-resistant rubber gaskets further enhance longevity. Fine vacuum adjustment, a clear viewing chamber, and overload protection make operation safe and straightforward for all users.

Compliant and Versatile Operation

Meeting international standards ASTM D2041 and AASHTO T209, this equipment is a reliable choice for laboratories, exporters, manufacturers, and traders within India. With both manual and automatic control modes, and a low noise level (<65 dB(A)), it adapts to varied testing environments, ensuring efficient and quiet operation.

FAQs of ASPHALT MIXER-THEORETICAL DENSITY METER-WITH VACUUM PUMP:

Q: How does the theoretical density meter measure the maximum specific gravity of asphalt?

A: The instrument uses a vacuum pump to remove air from a sample of asphalt mix placed in a sealed flask. The resulting measurement, performed as per ASTM D2041 or AASHTO T209, allows for accurate determination of the theoretical maximum specific gravity, essential for quality control in road construction.Q: What is the typical process for conducting a Rice Test using this device?

A: Begin by placing a representative asphalt sample (10004000 g) into the heavy-duty borosilicate glass flask. After securing the chamber, activate the vacuum pump to reach a vacuum of up to 13.3 kPa, hold for the required period, and monitor the process via the analog gauge. The fine adjustment valve ensures precise vacuum control for consistent results.Q: When and where should this theoretical density meter be used?

A: This equipment is primarily used in laboratory settings, such as civil engineering labs, quality control facilities, and research institutes. It is suitable whenever there is a need to determine the asphalt mixtures maximum specific gravity, typically during road construction material assessments and routine quality checks.Q: What are the key benefits of using this instrument for asphalt testing?

A: The meter provides highly accurate and reproducible results, critical for evaluating asphalt compaction and performance. Its robust construction, integrated vacuum pump, and simple manual or automatic controls make it efficient, safe, and long-lasting, directly improving the reliability of test outcomes and aiding in compliance with industry standards.Q: How many samples can be tested at one time, and what is the specimen capacity?

A: The device is designed to test one specimen per cycle, with each test accommodating a sample size typically ranging from 1000 to 4000 g. The flask has a total capacity of 5 liters, providing ample space for thorough testing as specified by relevant standards.Q: What included accessories support the operation of the density meter?

A: The package includes a desiccator, vacuum hoses, a release valve, and a removable vacuum gauge. These components facilitate accurate testing, efficient vacuum application, and easy maintenance, ensuring smooth day-to-day operations in the lab.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Civil Testing Instruments Category

ABRASION RESISTANCE TESTING MACHINE FOR GEOTEXTILE

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Automation Grade : SemiAutomatic

Product Type : ABRASION RESISTANCE TESTING MACHINE FOR GEOTEXTILE

Features : Robust construction, adjustable test parameters, digital counter

Usage : Civil Engineering Testing Equipment

Drilling Fluid Testing Equipment

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Automation Grade : SemiAutomatic

Product Type : Drilling Fluid Testing Equipment

Features : Corrosionresistant, portable design, easy calibration, multipurpose

Usage : Drilling Fluid Testing Equipment

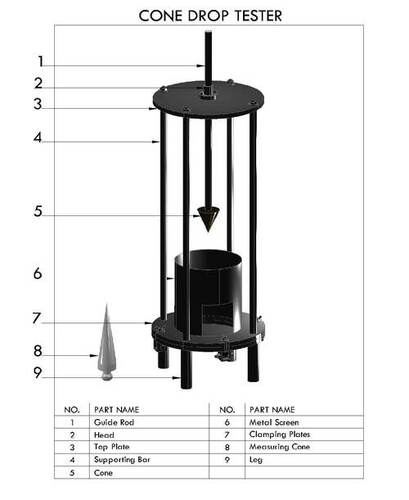

Cone Drop Tester

Price 1.00 INR / Number

Minimum Order Quantity : 1 Piece

Automation Grade : Manual

Product Type : Cone Drop Tester FOR GEOSYNTHETIC (DYNAMIC PERFORATION TESTER)

Features : Robust frame, removable specimen holder, simple operation

Usage : Civil Engineering Testing Equipment

DIRECT READING GSM BALANCE-GRAMMAGE TESTER

Price 1.00 INR / Number

Minimum Order Quantity : 1 Number

Automation Grade : Manual

Product Type : DIRECT READING GSM BALANCEGRAMMAGE TESTER

Features : Direct reading, highly accurate balance, sturdy base, anticorrosive finish

Usage : Civil Engineering Testing Instrument

|

EIE INSTRUMENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry