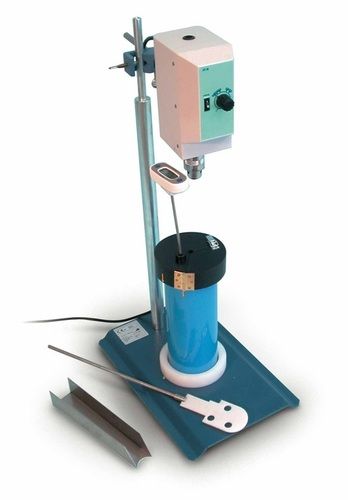

Jolting Apparatus

Jolting Apparatus Specification

- Application

- Used to compact rectangular 40 x 40 x 160mm of port land and pozzolana cement mortar prism specimens for determining the transverse strength.

- Product Type

- Vibrating Table For Cement Mortar

- Automation Grade

- Semi Automatic

- Weight

- 40 Kilograms (kg)

- Features

- Accurate results, Robust construction, Efficient working

- Dimension (L*W*H)

- 1070 X 410 X 510 (L X W X D) mm Millimeter (mm)

- Operate Method

- Electric

- Usage

- Cement Testing Equipment

- Machine Weight

- 40 Kilograms (kg)

Jolting Apparatus Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 100 Pieces Per Month

- Delivery Time

- 8 Week

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Box / Corrugated Box

- Certifications

- ISO 9001 : 2015

About Jolting Apparatus

Applications:

Used to compact rectangular 40 x 40 x 160mm of port land and pozzolana cement mortar prism specimens for determining the transverse strength.

Also known asVIBRATING TABLE FOR CEMENT MORTAR

Furtherdetails available on our website.

The Price mentioned here are subject to change as per the capacity,specifications and application of the user.

Streamlined Cement Mortar Testing

Our Jolting Apparatus simplifies the compaction process of cement mortar prisms, providing consistent and repeatable results essential for quality cement analysis. Its precise mechanical action helps laboratories achieve reliable transverse strength determinations for Portland and pozzolana cement in compliance with standard testing protocols. This apparatus is an indispensable tool for maintaining stringent cement quality controls.

Durable Build and Practical Design

Manufactured with a weight of 40 kg and dimensions of 1070 x 410 x 510 mm, this equipment is engineered for stability and durability during operation. Its compact structure allows easy placement in laboratories while ensuring operational efficiency, making it a valuable asset for cement testing teams and professionals.

FAQs of JOLTING APPARATUS:

Q: How does the Jolting Apparatus improve cement mortar testing?

A: The Jolting Apparatus ensures uniform compaction of 40 x 40 x 160 mm cement mortar prisms, leading to more accurate and repeatable transverse strength results. By automating the jolting process, it minimizes manual errors and achieves consistent sample preparation in line with industry standards.Q: What is the process for using the Jolting Apparatus?

A: To use the apparatus, place the prepared mortar specimen in the specified mold. Secure the mold onto the device, set the required number of jolts, and initiate the machine. The apparatus will compact the mortar specimen through controlled jolting, readying it for strength testing.Q: When is the Jolting Apparatus typically used during cement testing?

A: It is used prior to strength testing, specifically after preparing fresh cement mortar and before testing the prisms for transverse strength. This step ensures the prisms have been compacted properly and uniformly.Q: Where is the Jolting Apparatus usually installed or used?

A: The apparatus is typically installed and used in material testing laboratories, research and quality control labs within cement manufacturing plants, and third-party testing facilities specializing in building materials.Q: What are the benefits of using this apparatus in cement testing?

A: Utilizing the Jolting Apparatus guarantees uniform sample compaction, reduces human error, and enables laboratories to produce reliable and comparable test results, which is crucial for maintaining high-quality cement production.Q: Is this apparatus suitable for different types of cement?

A: Yes, the Jolting Apparatus is designed to compact specimens made of both Portland and pozzolana cement mortar, accommodating a variety of cement types in standard testing practices.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Cement Testing Equipment Category

COMPRESSION FRAME JIG ASSEMBLY

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : Compression Frame Jig Assembly

Features : Rugged steel body, precision alignment, simple operation, reusable

Usage : For Cement Testing

Application : This jig is designed for testing of 40 x 40 x 160mm cement prism after breaking in Flexure and also can be adapted with 50mm platen to test 2 or 50mm mortar cement cube specimen

Lime Reactivity Test Apparatus

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : Cement Testing Equipment`

Features : Corrosionresistant construction, Easy to operate, Glass thermometric tube

Usage : Cement Testing Equipment

Application : Used for determining the reactivity on slaking of ground quicklime.

MARSH CONE FUNNEL - FOR BENTONITE VISCOSITY

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : MARSH CONE FUNNEL PLASTIC FOR BENTONITE VISCOSITY WITH MEASURING JUG

Features : Lightweight, portable, easy to clean

Usage : Cement Testing Equipment

Application : This test can be performed in the laboratory, or used in the field to assess the apparent viscosity of a clay slurry for quality control purposes.

Shrinkage Bar Mould

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : Shrinkage Bar Mould

Features : Corrosion resistant, rigid construction, precise dimensions

Usage : Cement Testing Equipment

Application : For measurement of drying shrinkage. Length measuring device, reference points of 6.5mm dia and all other accessories required for the drying shrinkage test are to be purchased separately

|

EIE INSTRUMENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry