Curing Tank for Cement Mortar Cubes

Price 1.00 INR/ Piece

Curing Tank for Cement Mortar Cubes Specification

- Dimension (L*W*H)

- Inner dimension: 1.5M X 1.5M X 0.60M Millimeter (mm)

- Mounting Type

- Floor Mounted

- Accuracy

- 2C

- Specimen Size

- 70.6mm x 70.6mm x 70.6mm

- Temperature

- Maintained at 27C 2C

- Frequency

- 50 Hz

- Operating Voltage

- 230V

- Number of Specimens

- Accommodates up to 50 cubes

- Port Size

- Standard Water Inlet/Outlet

- Equipment Type

- Curing Tank

- Interface Type

- Simple ON/OFF Switch

- Display Type

- Digital Display

- Product Type

- Curing Tank for Cement Mortar Cubes

- Max Height

- 0.60M (Inner Height)

- Resolution

- 0.1C

- Application

- FOR CONDITIONING OF CEMENT TEST SAMPLES

- Response Time

- Instant

- Automation Grade

- Semi-automatic

- Usage

- For Cement Testing

- Features

- Fitted with digital temperature controller, overflow and drainage facility

- Humidity

- 95% RH (Relative Humidity)

- Power Supply

- 230V AC, 50 Hz

- Capacity

- Approx. 1350 Liters

- Machine Weight

- Approx. 85 kg

- Control Mode

- Digital Temperature Control

- Drainage Facility

- Yes, provided

- Material

- High-density plastic/Fiber Reinforced Polymer (FRP)

- Heater Type

- Immersion Heater

- Lid Type

- Removable polycarbonate lid

- Insulation

- Thermal insulation provided

- Water Circulation

- Uniform water circulation for consistent curing

- Safety Features

- Overheat protection

- Compliance

- IS:10086 & IS:516 standards

- Installation

- Indoor, laboratory use

- Tank Finish

- Corrosion Resistant, Smooth

- Overflow Mechanism

- Built-in overflow

Curing Tank for Cement Mortar Cubes Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 100 Pieces Per Month

- Delivery Time

- 8 Week

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Box / Corrugated Box

- Certifications

- ISO 9001 : 2015

About Curing Tank for Cement Mortar Cubes

FOR CONDITIONING OF CEMENT TEST SAMPLES

Tank will consist of a rectangular double walled metal cabinet, inner chamber made of thick gauge stainless steel. Outer chamber made of Galvanized sheet powder coated. Specially designed L shaped High wattage heaters will be mounted in the chamber in such a way that, it facilitates easy replacement within 5 minutes by normal skilled person. It will have facility to circulate water inside the chamber by stirrer to maintain the uniform temperature of water. Inside the chamber there will be a heavy gauge stainless steel perforated platform with ribs to withstand the heavy load of the cubes. It will also have a lid with lifting handle to cover the chamber.

Furtherdetails available on our website.

The Price mentioned here are subject to change as per the capacity,specifications and application of the user.

Advanced Features for Consistent Curing

The tanks digital temperature control, immersion heater, and thermal insulation maintain water temperature at 27C 2C for accurate curing conditions. A built-in overflow, uniform water circulation, and drainage facilities offer seamless operation with reliable results. The removable polycarbonate lid and overheat protection enhance user safety and convenient access during sample placement and removal.

Compliant and Versatile Curing Solution

Specially designed for conditioning cement test samples, this curing tank meets IS:10086 & IS:516 standards, making it suitable for laboratories involved in cement testing. Its 1.5m x 1.5m x 0.60m inner dimensions can accommodate up to 50 mortar cubes. The sturdy, floor-mounted construction and semi-automatic operation ensure ease of use and consistent performance in demanding laboratory environments.

Simple Installation and Operation

Installing the curing tank is straightforwardfloor mount it indoors, connect to a standard 230V AC power supply, and utilize the simple ON/OFF switch and digital display for operation. Regular water inlet and outlet ports are provided for easy setup and maintenance, while the precision-controlled environment enhances the reliability and accuracy of cement testing processes.

FAQs of Curing Tank for Cement Mortar Cubes:

Q: How does the curing tank ensure uniform curing of cement mortar cubes?

A: The tank features uniform water circulation, thermal insulation, and a digital temperature controller to maintain a constant temperature of 27C 2C, ensuring that every cement mortar cube receives consistent curing as per IS:10086 & IS:516 standards.Q: What is the process for using the curing tank in a laboratory setting?

A: Place the prepared cement cubes inside the tank, fill with water up to the required level, set the desired temperature using the digital controller, and activate circulation and heating. The removable lid provides easy access, and built-in overflow and drainage facilitate routine maintenance.Q: When should the curing tank be used during cement testing?

A: The curing tank is used after casting the cement mortar cubes, specifically during the conditioning phase, where samples must be kept at controlled temperature and humidity to ensure accurate strength testing results.Q: Where is the ideal location to install the curing tank?

A: This curing tank is designed for indoor laboratory use and should be floor-mounted in a controlled environment to maintain optimal humidity and temperature standards required for cement sample conditioning.Q: What are the main benefits of using an FRP or high-density plastic curing tank?

A: High-density plastic and FRP construction offer corrosion resistance, durability, and easy cleaning. Combined with features like digital control, insulation, and overheat protection, these materials ensure a long service life and reliable performance.Q: How many cement specimens can the tank accommodate at once?

A: The curing tank can accommodate up to 50 cement mortar cubes of 70.6mm x 70.6mm x 70.6mm size, making it suitable for batch testing in laboratory environments.Q: What safety features are incorporated in the curing tank?

A: The curing tank is equipped with overheat protection for user safety, a digital display for monitoring, a removable polycarbonate lid, and an instant response time for temperature corrections, ensuring safe and efficient operation in the laboratory.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Cement Testing Equipment Category

Automatic Compression/Flexural Testing Machine

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Machine Weight : Approx. 350 kg

Usage : Laboratory / Industrial

Features : Overload protection, Data storage, Autocalibration

Application : Compression and flexural strength testing of concrete specimens

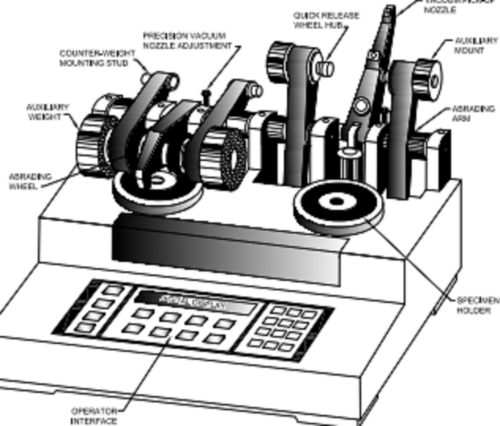

DETERMINATION OF RESISTANCE TO ABRASION

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Machine Weight : 40 Kg

Usage : laboratory

Features : Corrosion resistant

Application : Industrial

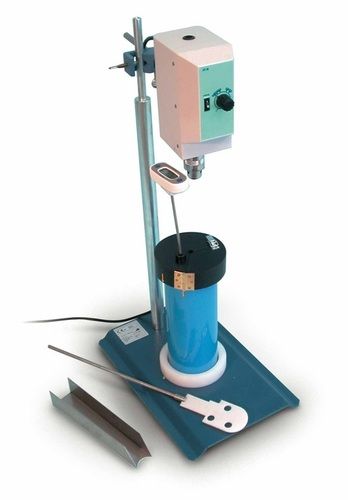

Southard Viscometer

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Machine Weight : 8 kg

Usage : Cement Testing Equipment

Features : Robust Construction, Corrosion Resistant Vessel, Easy Cleaning

Application : The Southard viscosimeter shall be used for adjusting the consistency of the putty and a vessel of the shape and dimensions which shall be used for the determination of the volume yield.Â

Lime Reactivity Test Apparatus

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Machine Weight : Approx. 15 kg

Usage : Cement Testing Equipment

Features : Corrosionresistant construction, Easy to operate, Glass thermometric tube

Application : Used for determining the reactivity on slaking of ground quicklime.

|

EIE INSTRUMENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry