FLOW TABLE Hand Operated

Price 1.00 INR/ Piece

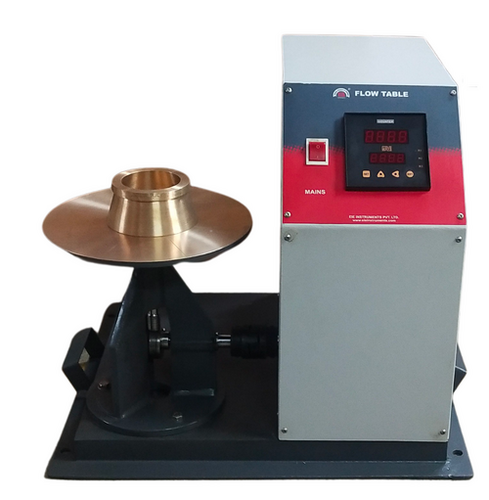

FLOW TABLE Hand Operated Specification

- Usage

- Cement Testing Equipment

- Equipment Type

- Hand Operated Flow Table

- Measuring Range

- Up to 300 mm (table diameter)

- Response Time

- Immediate (manual)

- Automation Grade

- Manual

- Product Type

- Flow Table for Cement Hand Operated

- Test Range

- Standard for cement flow tests

- Application

- Determining flow of cement paste/mortar

- Dimension (L*W*H)

- 150 X 360 X 270 (L X W X D) mm Millimeter (mm)

- Features

- Cast iron table with engraved lines, hand lever mechanism, conforming to standards

- Interface Type

- Manual (hand lever)

- Accuracy

- As per IS: 5512/1976

- Humidity

- Ambient

- Specimen Size

- Standard cement paste (as per IS: 5512/1976)

- Temperature

- Ambient

- Mounting Type

- Table top

- Display Type

- Graduated scale on table

- Max Height

- 270 mm (overall)

- Power Supply

- Not required (Manual)

- Resolution

- 1 mm (graduated scale)

- Number of Specimens

- Single per test

- Frequency

- Manual operation

- Machine Weight

- Approx. 15 kg

- Test Speed

- Hand operated (manual control)

- Test Width

- 300 mm (table dia.)

- Test Stroke

- 15 drops (standard test)

- Control Mode

- Manual lever operation

- Finish

- Corrosion resistant coating

- Level Adjustment

- Equipped with leveling screws on table base

- Operation Method

- Lever-lifted and dropped by cam mechanism

- Surface Marking

- Engraved concentric circles for measurement

- Accessories Supplied

- Brass mould and tamping bar (optional)

- Color

- Blue/Black (as per manufacturer)

- Material of Table

- Cast Iron with machined finish

- Packing Type

- Export worthy wooden box

FLOW TABLE Hand Operated Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 100 Pieces Per Month

- Delivery Time

- 8 Week

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Box / Corrugated Box

- Certifications

- ISO 9001 : 2015

About FLOW TABLE Hand Operated

The flow table consists of a brass table top mounted on a rigid stand. The table top is reinforced with equally disposed ribs and allowed to drop through 12 mm by a ground and hardened cam, Complete with mould - 100 mm base dia, 70 mm top dia and 50 mm high.

Further details availableon our website.

The Price mentioned here are subject to change as per the capacity,specifications and application of the user.

Precision and Durability

Constructed from robust cast iron with a machined finish and corrosion-resistant coating, the Flow Table ensures longevity and repeatable accuracy. The engraved concentric circles on the table surface aid in exact measurement, while the sturdy manual lever mechanism delivers controlled and consistent drops, conforming to standardized test requirements.

User-Friendly Operation

The table is designed for manual operation, featuring a cam-lifted lever and easy-to-read graduated scale. Level adjustment is simple with integrated leveling screws, and the equipment can be operated without any external power supply. Its compact design makes it ideal for tabletop use in various laboratory and field environments.

Comprehensive Accessories and Packing

The Flow Table is supplied with an optional brass mould and tamping bar for complete testing needs. All components are securely packed in an export-worthy wooden box, ensuring safe transportation and handling. The tables blue/black finish offers both a professional appearance and added protection against wear.

FAQs of FLOW TABLE Hand Operated:

Q: How is the FLOW TABLE Hand Operated used for testing cement paste or mortar?

A: The table is used to determine the flow of cement paste or mortar by placing a standard specimen on the table, then raising and dropping the table 15 times using the hand lever and cam mechanism. The spread of the material is measured on the engraved concentric circles, following IS: 5512/1976 specifications.Q: What are the benefits of the cast iron table with a corrosion-resistant finish?

A: A cast iron table provides strength and stability, essential for repeated testing. The corrosion-resistant finish extends the lifetime of the table, making it suitable for use in harsh laboratory environments and ensuring measurement accuracy over time.Q: When should manual flow table tests be performed during construction projects?

A: Manual flow table tests should be conducted when evaluating the workability and uniformity of cement pastes or mortars, especially for quality control purposes in laboratory or field settings, and during compliance checks with IS: 5512/1976 standards.Q: Where can the Hand Operated Flow Table be set up for use?

A: This table-top equipment can be used in laboratories, construction sites, cement factories, or research institutionsanywhere standardized flow tests are required. Its compact size and durable packing make it suitable for both stationary and mobile labs.Q: What is the process for adjusting the level of the flow table during setup?

A: The table features leveling screws on its base. To ensure accurate test results, these screws are adjusted until the tables surface is perfectly horizontal before placing any specimen and beginning the test procedure.Q: What accessories are supplied with the FLOW TABLE and are they necessary for testing?

A: Optional accessories such as a brass mould and tamping bar are available to facilitate standard specimen preparation, improving consistency and compliance with test protocols. These tools enhance ease of use and help achieve precise results.Q: What is the measuring range of the Flow Table and how is accuracy maintained?

A: The tables measuring range is up to 300 mm in diameter, with measurements displayed on an engraved graduated scale offering 1 mm resolution. Adherence to IS: 5512/1976, coupled with immediate manual response and stable construction, ensures continued accuracy.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Cement Testing Equipment Category

Length Comparator - Digital

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Features : High accuracy, portable, easy calibration

Application : Precision length comparison and calibration

Automation Grade : SemiAutomatic

Usage : Calibration Lab, Metrology

FLOW TABLE MOTORISED for Cement

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Features : Corrosionresistant tabletop, nonslip base, automatic count

Application : Flow test for cement and mortar

Automation Grade : Semiautomatic

Usage : Cement Testing Equipment

Vicat Needle Apparatus for Gypsum

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Features : Supplied complete with a dashpot, Vicat mould, initial/final setting needles, glass plate, plunger, graduated scale

Application : Is used to determine the volume of water required for mixing Gypsum Plaster When performing the setting time and compressive strength test.

Automation Grade : Manual

Usage : Cement Testing Equipment

Accelerated Curing Tank

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Features : Double Walled Construction, Water Circulation, Digital Temperature Control

Application : Curing of Concrete Test Specimens

Automation Grade : SemiAutomatic

Usage : Industrial

|

EIE INSTRUMENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry