Straight Edge with Measuring Wedge

Straight Edge with Measuring Wedge Specification

- Equipment Type

- Straight Edge with Measuring Wedge

- Product Type

- Bitumen Testing Equipment

- Color

- Blue

- Features

- Accurate results, Robust construction, Efficient working

- Usage

- Bitumen Testing Equipment

- Material

- Mild Steel

- Automation Grade

- Manual

- Dimension (L*W*H)

- 3370 x 100 x 200(L X W X D) mm Millimeter (mm)

- Application

- Used to measure irregularities in road pavement.

- Suitable For

- Road Construction, Highway Inspection, Bitumen Pavement Quality Control

- Finish

- Powder Coated / Painted

- Equipment Type

- Straight Edge With Measuring Wedge

- Colour

- Grey / Blue

- Material

- Mild Steel

- Straight Edge Length

- 3 metres (approx.)

- Measuring Wedge Range

- 0-25 mm

- Wedge Graduation

- 1 mm

Straight Edge with Measuring Wedge Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 300 Pieces Per Month

- Delivery Time

- 4 Week

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Box / Corrugated Box

- Certifications

- ISO 9001 : 2015

About Straight Edge with Measuring Wedge

Details

- Used to measure irregularities in road pavement.

- Made from Mild Steel Material

- 3 Meter in length

- Complete with measuring wedge

Further details availableon our website.

The Price mentioned here are subject to change as per the capacity,specifications and application of the user.

Accurate Surface Measurement for Roads

Ensure your road and pavement projects meet quality standards with the Straight Edge with Measuring Wedge. Its three-metre mild steel body is perfect for detecting irregularities in bitumen and other road surfaces, providing precise measurements for project assessments and quality control.

Durable and Reliable Design

Manufactured from robust mild steel and finished with powder coating or paint, this equipment withstands harsh site conditions. Its practical design makes it an essential instrument in road construction and inspection, ensuring longevity and consistent performance.

FAQs of STRAIGHT EDGE WITH MEASURING WEDGE:

Q: How is the Straight Edge with Measuring Wedge used in road construction?

A: This instrument is placed on the pavement surface to check for unevenness. The accompanying measuring wedge is slid under the straight edge to measure surface irregularities ranging from 0 to 25 mm, ensuring pavement smoothness and compliance with standards.Q: What is the advantage of using a measuring wedge with 1 mm graduations?

A: The 1 mm graduation on the measuring wedge allows for precise measurement of pavement deviations. This accuracy helps in identifying even minor irregularities, ensuring higher quality control during road construction and inspection.Q: Where can the Straight Edge with Measuring Wedge be used?

A: It is suitable for road construction sites, highway inspections, and any setting where bitumen pavement quality is critical. The tool is extensively used by construction professionals and quality control teams across India.Q: What are the main benefits of using this equipment for bitumen pavement testing?

A: The primary benefits include its ability to deliver quick and accurate measurements, facilitate compliance with government standards, and improve pavement longevity by identifying irregularities early in the construction process.Q: When should this tool be used during pavement construction?

A: The Straight Edge with Measuring Wedge should be used during and after the laying of bitumen pavements or road surfaces to continuously monitor and verify surface regularity, ensuring project quality throughout construction.Q: What maintenance is required for the straight edge and wedge?

A: Routine cleaning after use and proper storage are recommended to maintain the accuracy and longevity of both the straight edge and the measuring wedge, especially given their mild steel construction and protective finish.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

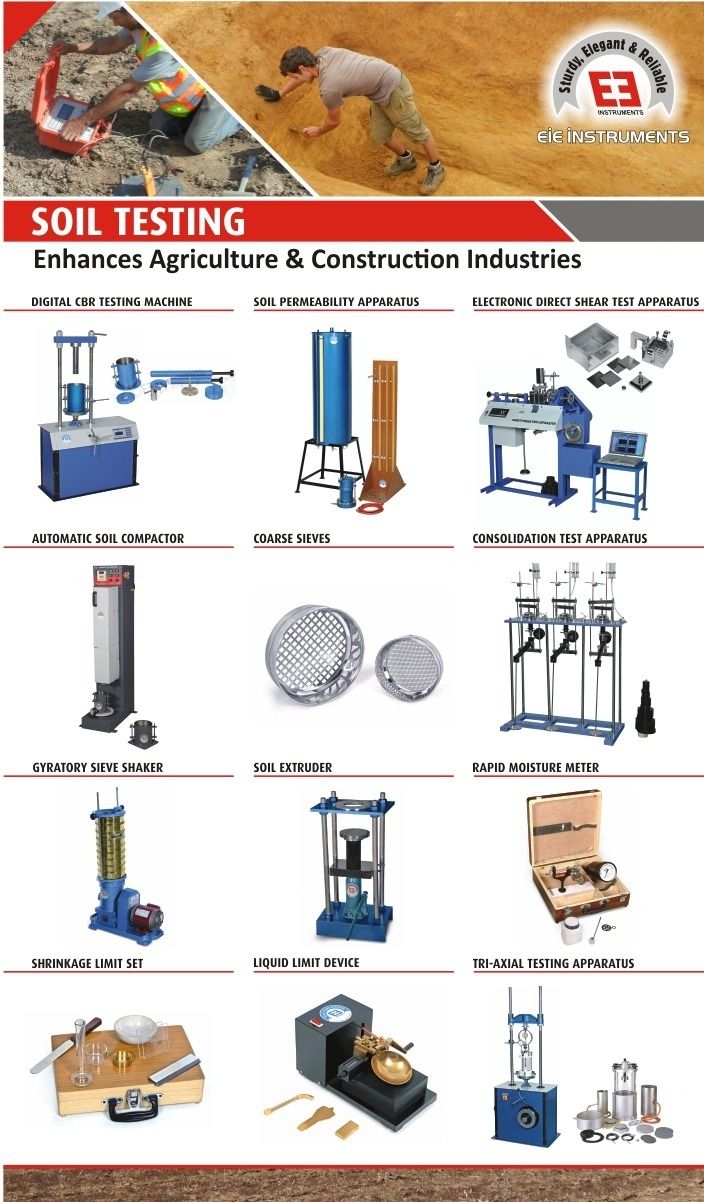

More Products in Aggregate Testing Equipments Category

ACCELERATED AGGREGATE (ROADSTONE) POLISHING MACHINE

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : ACCELERATED AGGREGATE (ROADSTONE) POLISHING MACHINE

Usage : AGGREGATE TESTING EQUIPMENTS

Features : Heavy duty, low maintenance, corrosion resistant

Automation Grade : SemiAutomatic

VACUUM PYCNOMETER

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : VACUUM PYCNOMETER FOR GMM RICE TEST

Usage : Bitumen Testing Equipment

Features : Robust glass container, easy to clean, corrosionresistant fittings, leakproof operation

Automation Grade : Manual

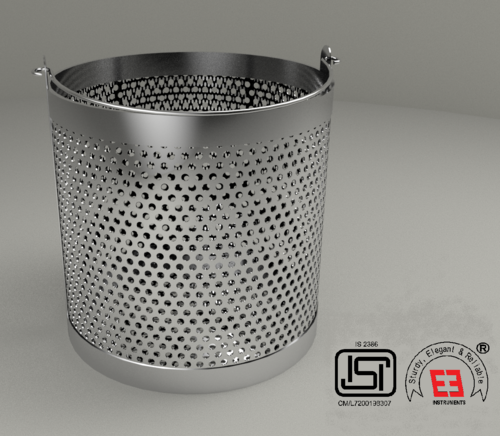

ISI Marked - Density Basket

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : ISI Marked Density Basket

Usage : Aggregate Testing Equipment

Features : ISI Marked, Constructed from GI wire mesh, corrosion resistant

Automation Grade : Manual

ISI Marked - Flakiness Gauge

Price 01 INR / Number

Minimum Order Quantity : 1 Piece

Product Type : ISI Marked Flakiness Gauge

Usage : Aggregate Testing Equipment

Features : ISI Marked, Durable, Corrosion Resistant, Precision Machined Slots

Automation Grade : Manual

|

EIE INSTRUMENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry