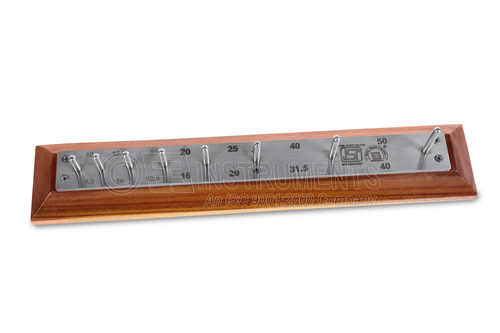

ISI Marked - Flakiness Gauge

Price 01 INR/ Number

ISI Marked - Flakiness Gauge Specification

- Max Height

- 0.5 inch (thickness)

- Power Supply

- Not Required (Manual Instrument)

- Product Type

- ISI Marked - Flakiness Gauge

- Number of Specimens

- One at a time

- Equipment Type

- ISI Marked - Flakiness Gauge

- Features

- ISI Marked, Durable, Corrosion Resistant, Precision Machined Slots

- Dimension (L*W*H)

- 17x 6x 0.5 (LxWxH) Millimeter (mm)

- Measuring Range

- As per specification IS:2386 (Part-1)

- Specimen Size

- As per slot width; accommodates nominal size 63mm to 6.3mm aggregates

- Mounting Type

- Portable/Handheld

- Response Time

- Immediate (Manual Judgment)

- Resolution

- According to slit dimensions

- Test Range

- For aggregate particles size as per IS:2386 (Part-1)

- Usage

- Aggregate Testing Equipment

- Automation Grade

- Manual

- Application

- Used to determine the percentage of particles in a coarse aggregate material that have a thickness (smallest dimension) of less than one-half of the nominal size

- Accuracy

- High adherence to ISI standards

- Control Mode

- Manual

- Usage Area

- Civil Engineering Laboratory, Construction Material Testing

- Cut Slot Sizes

- 63mm, 50mm, 40mm, 31.5mm, 25mm, 20mm, 16mm, 12.5mm, 10mm, 6.3mm

- Included Accessories

- Carrying Case (as per supplier)

- Finish

- Polished/Chemically Treated for Corrosion Resistance

- Material of Construction

- Mild Steel with Chrome Plating or as per ISI standard

ISI Marked - Flakiness Gauge Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 200 Pieces Per Month

- Delivery Time

- 4 Week

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Box / Corrugated Box

- Certifications

- ISO 9001 : 2015

About ISI Marked - Flakiness Gauge

Purpose:

Used to determine the percentage of particles in a coarse aggregate material that have a thickness (smallest dimension) of less than one-half of the nominal size. Particle is flaky when its thickness (smallest dimension) is less than 0.6 of the mid-size of the sieve fraction.

Significance and Use:

Aggregates which are flaky and/or elongated will often lower the workability of a concrete mix and may also affect long term durability. In bituminous mixtures, flaky aggregate makes for a harsh mix and may also crack and break up during compaction by rolling.

Construction Details:

- It consists of aCRC Sheet frame with M.S. sliding panel.

- The panel has slots, which are accurately cut, in standard different length and width.

- Gauge has seven labeled slots for rapid hand trying of particles from each of the seven sieve cuts.

- Having following Normal Aperture size as per India Standard : 63, 50, 40, 31.5, 25, 20, 16, 12.5, 10, 6.3 mm

Furtherdetails available on our website.

The Price mentioned here are subject to change as per the capacity,specifications and application of the user.

Precision-Crafted for Reliable Aggregate Testing

Engineered with meticulous attention to detail, the ISI Marked Flakiness Gauge meets the requirements of IS:2386 (Part-1), ensuring reliable and reproducible evaluation of aggregate flakiness. This makes it indispensable for civil engineering laboratories, construction material testing, and aggregate analysis.

Durable Construction and Corrosion Resistance

Manufactured from high-quality mild steel with chrome plating or chemically treated finishes, the gauge is built to resist corrosion and provide enduring performance in demanding laboratory and field environments. The polished, easy-to-clean surface further enhances its utility and lifespan.

Portable Design for Versatile Use

With a compact dimension of 17 x 6 x 0.5 mm and an included carrying case, this manual, handheld instrument is perfectly suited for use in varied testing environments. Its portability ensures that precise flakiness analysis can be conducted directly at construction sites or remote locations.

FAQs of ISI Marked - Flakiness Gauge:

Q: How is the ISI Marked Flakiness Gauge used in aggregate testing?

A: To use the Flakiness Gauge, aggregate particles are passed through designated slots corresponding to their nominal size. Particles that pass through slots with thickness less than half their nominal size are classified as flaky as per IS:2386 (Part-1) standards. The percentage of flakiness is then calculated manually.Q: What materials are used in the construction of this flakiness gauge?

A: The gauge is constructed from mild steel with a chrome-plated or ISI-standard finish. It is also chemically treated or polished, providing excellent resistance to corrosion and enhancing durability.Q: When is this device typically required in construction processes?

A: The Flakiness Gauge is most commonly used during the quality control phase of aggregate preparation for concrete or road construction. It helps verify that aggregates meet the necessary specifications for flakiness before incorporation into the final mix.Q: Where can the ISI Marked Flakiness Gauge be used?

A: Thanks to its portable and robust design, the Flakiness Gauge can be used both in civil engineering laboratories and directly on construction sites. Its carrying case ensures safe transportation to various field locations.Q: What is the testing process using this gauge?

A: Aggregate samples are first sized, and each specimen is individually tested by passing it through the relevant slots on the gauge. The tester identifies flaky particles as those passing through slots less than half their nominal size and then records the results for analysis.Q: What are the benefits of using an ISI Marked Flakiness Gauge?

A: By strictly adhering to ISI standards, the gauge ensures accurate, repeatable results for flakiness analysis. Its sturdy, corrosion-resistant construction guarantees longevity and dependable results even under repeated use, making it a valuable tool for quality assurance in construction projects.Q: Does the Flakiness Gauge require any power supply for operation?

A: No power supply is needed, as the gauge operates fully manually. All measurements and assessments are performed by hand, offering immediate results during testing.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Aggregate Testing Equipments Category

VACUUM PYCNOMETER

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Bitumen Testing Equipment

Features : Robust glass container, easy to clean, corrosionresistant fittings, leakproof operation

Product Type : VACUUM PYCNOMETER FOR GMM RICE TEST

Application : Used for determining the theoretical maximum specific gravity of uncompacted bituminous paving mixtures.

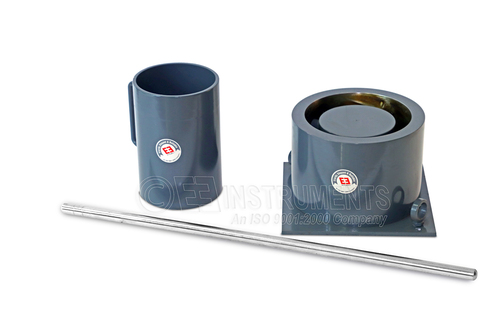

Aggregate Crushing Value Apparatus

Price 1.00 INR / Piece

Minimum Order Quantity : 1

Usage : Aggregate Testing Equipment

Features : Rugged construction, corrosionresistant finish, easy to use

Product Type : AGGREGATE CRUSHING VALUE TEST APPARATUS

Application : Aggregate testing for civil engineering

ISI Marked - Length Gauge

Price 3000 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Aggregate Testing Equipment

Features : Six hardened steel pins for aggregate measurement, ISI Marked, corrosion resistant

Product Type : ISI Marked Length Gauge

Application : This instrument is used to determine the elongation index of aggregates

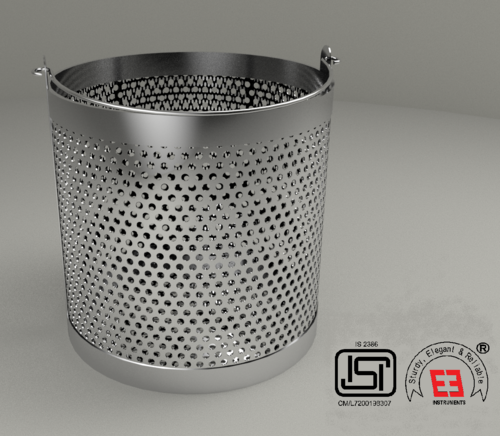

ISI Marked - Density Basket

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Aggregate Testing Equipment

Features : ISI Marked, Constructed from GI wire mesh, corrosion resistant

Product Type : ISI Marked Density Basket

Application : Aggregate Testing

|

EIE INSTRUMENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry