VACUUM PYCNOMETER

Price 1.00 INR/ Piece

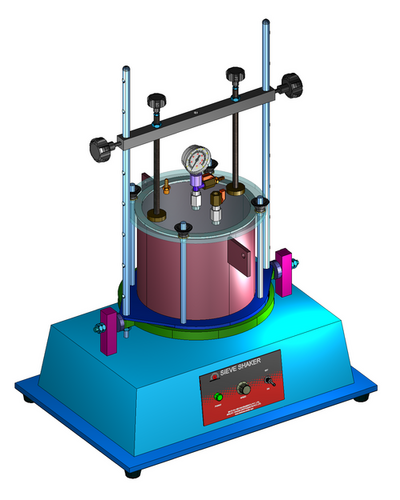

VACUUM PYCNOMETER Specification

- Display Type

- Analog gauge

- Temperature

- Ambient temperature, typically 5C to 45C

- Power Supply

- 220-240V AC, 50Hz

- Operating Voltage

- 220V AC

- Response Time

- <5 seconds to reach vacuum

- Hardness

- Glass container; chemical resistant fittings

- Specimen Size

- 1 liter capacity per pycnometer

- Port Size

- 1/4 & 3/8 hose connection

- Accuracy

- 0.01 gm/cm

- Test Range

- Up to 4000 gm of sample

- Application

- Used for determining the theoretical maximum specific gravity of uncompacted bituminous paving mixtures.

- Number of Specimens

- Up to 4 pycnometers simultaneously

- Automation Grade

- Manual

- Measuring Range

- 0.01 to 2.5 gm/cm

- Max Height

- Approx. 32 cm

- Frequency

- 50Hz

- Usage

- Bitumen Testing Equipment

- Gas Pressure

- Below atmospheric pressure (vacuum up to 30 mm Hg)

- Resolution

- 0.01 gm/cm

- Product Type

- VACUUM PYCNOMETER FOR GMM RICE TEST

- Mounting Type

- Bench-top

- Interface Type

- Hose/Tube connection

- Humidity

- 090% RH operating range

- Features

- Robust glass container, easy to clean, corrosion-resistant fittings, leak-proof operation

- Capacity

- 1 liter

- Machine Weight

- Approx. 18 kg

- Test Speed

- Manual process - no direct speed specification

- Control Mode

- Manual control

- Seal Type

- Rubber gasket

- Finish

- Laboratory grade chemical resistant

- Sample Container

- 1 litre volumetric flask

- Equipment Type

- Bitumen Testing - Laboratory Equipment

- Vacuum Gauge Range

- 0760 mm Hg

- Vacuum Pump Type

- Oil-less diaphragm type

- Material of Construction

- Borosilicate glass, stainless steel fittings

- Accessories Included

- Vacuum tubing, vacuum pump, pycnometer flasks

VACUUM PYCNOMETER Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 100 Pieces Per Month

- Delivery Time

- 4 Week

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Box / Corrugated Box

- Certifications

- ISO 9001 : 2015

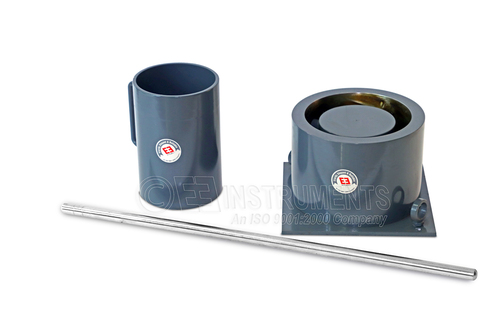

About VACUUM PYCNOMETER

Used for determining the theoretical maximum specific gravity of uncompacted bituminous paving mixtures. They can also be used for the calculation of the percent of air voids in compacted bituminous mixtures and the amount of bitumen absorbed by the aggregates. Supplied without Vibrating Table.

Features :

- Large capacity Vacuum Pycnometer

- It conveniently handles samples of 6,000 grams to minimize segregation effects.

- The unit is constructed from stainless steel sheet, with the upper half being transparent for visual observations of the effects of the vacuum.

- It is made from robust transparent acrylic sheet and is fitted with vacuum gauge, coupling for vacuum application and vent valve.

- Suitable for paving mixtures samples of max. 6000 g, with maximum aggregate size of 50 mm.

Supplied complete with following Accessories :

- Portable vacuum pump

- Silicon tubing for Vacuum

Further details availableon our website.

The Price mentioned here are subject to change as per the capacity,specifications and application of the user.

Optimal Design for Precision Testing

With its laboratory-grade, chemical-resistant borosilicate glass construction and stainless steel fittings, the Vacuum Pycnometer is engineered for accuracy and durability. The oil-less diaphragm vacuum pump and analog vacuum gauge ensure precise pressure monitoring and easy operation, allowing for consistent and reproducible test results while maintaining a safe and reliable working environment.

Easy Operation & Maintenance

The manual control system simplifies operation, requiring no direct speed specification. Setup and cleaning are straightforward thanks to the smooth glass surfaces and robust construction. Accessoriesincluding vacuum tubing, pump, and pycnometer flasksare included, supporting convenient, leak-proof operation. Its bench-top mount and manageable weight suit any well-equipped laboratory.

Versatile Applications in Bitumen Testing

The Vacuum Pycnometer is specifically designed for bitumen laboratory testing, determining maximum specific gravity in uncompacted paving mixtures. Its capacity to handle up to four specimens simultaneously increases productivity and repeatability for research facilities, manufacturers, and quality control labs concerned with road construction and paving material analysis.

FAQs of VACUUM PYCNOMETER:

Q: How does the Vacuum Pycnometer determine the specific gravity of bituminous mixtures?

A: The Vacuum Pycnometer uses a controlled vacuum environment to measure the volume and mass of bituminous paving mixtures. By creating a near-perfect vacuum (up to 30 mm Hg), air is removed from the sample, enabling accurate measurement of its theoretical maximum specific gravity using the 1-liter volumetric flask.Q: What are the primary benefits of using borosilicate glass and stainless steel fittings in this equipment?

A: Borosilicate glass offers excellent chemical resistance and durability for laboratory use, while the stainless steel fittings provide corrosion resistance and robust leak-proof operation. This combination ensures longevity, safety, and easy maintenance of the pycnometer even with frequent chemical exposure.Q: When and where is the Vacuum Pycnometer typically used?

A: This equipment is commonly used in civil engineering laboratories, paving material research facilities, and quality control departments during the evaluation of bituminous mixtures. It is especially relevant before the construction phase, ensuring materials comply with standards for maximum specific gravity.Q: What process is involved in using the Vacuum Pycnometer?

A: To operate, the sample is placed into the pycnometer, which is sealed with its rubber gasket and connected to the oil-less diaphragm vacuum pump. The operator manually applies a vacuum, monitors the pressure with the analog gauge, and after equilibrium, takes measurements to calculate specific gravity.Q: What sample size and throughput does the pycnometer support?

A: Each pycnometer flask holds up to 1 liter of sample, and the system can handle up to four specimens at once, allowing the testing of up to 4000 grams per cycle. This design increases laboratory throughput and efficiency.Q: How is the equipment maintained and cleaned?

A: Maintenance is straightforward: after testing, the borosilicate glass containers and stainless steel fittings can be easily cleaned using standard laboratory detergents. Ensure all rubber gaskets and hose connections are checked regularly for wear to maintain leak-proof operation.Q: What are the usage advantages of this Vacuum Pycnometer for bitumen testing?

A: The advantages include quick response time (under 5 seconds to reach vacuum), high accuracy (0.01 gm/cm), simultaneous specimen testing, robust chemical resistance, and reliable manual operation, making it a valuable tool for consistent and accurate bitumen analysis in any quality-focused lab.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

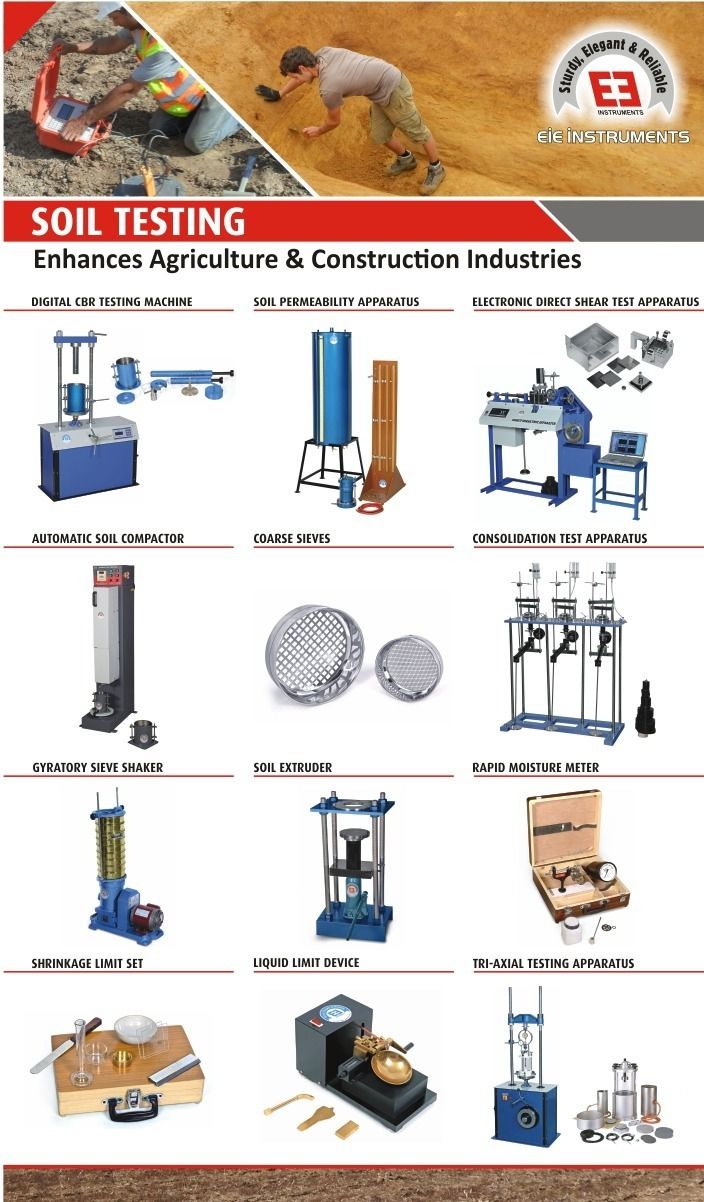

More Products in Aggregate Testing Equipments Category

ACCELERATED AGGREGATE (ROADSTONE) POLISHING MACHINE

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Application : Accelerated Polishing Machine. Specimens are manufactured in accurately machined and matched moulds; they are then removed from the moulds and located on the Road wheel.

Automation Grade : SemiAutomatic

Usage : AGGREGATE TESTING EQUIPMENTS

Product Type : ACCELERATED AGGREGATE (ROADSTONE) POLISHING MACHINE

Aggregate Testing Equipment

Price 1.00 INR / Piece

Minimum Order Quantity : 1

Application : Aggregate strength and durability testing

Automation Grade : Automatic

Usage : Industrial testing laboratory

Product Type : Aggregate Testing Equipment

Aggregate Crushing Value Apparatus

Price 1.00 INR / Piece

Minimum Order Quantity : 1

Application : Aggregate testing for civil engineering

Automation Grade : Manual

Usage : Aggregate Testing Equipment

Product Type : AGGREGATE CRUSHING VALUE TEST APPARATUS

Aggregate Impact Testing Machine

Minimum Order Quantity : 1 Piece

Application : For determining the aggregate impact value of coarse aggregate

Automation Grade : Automatic

Usage : Aggregate impact value gives a relative measure of the resistance of an aggregate to sudden shock or impact, which in some aggregates differs from its resistance to a slow compressive load.

Product Type : Aggregate Impact Testing Machine

|

EIE INSTRUMENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry