Aggregate Testing Equipment

Price 1.00 INR/ Piece

Aggregate Testing Equipment Specification

- Automation Grade

- Automatic

- Operating Voltage

- 230 V

- Measuring Range

- 0100%

- Equipment Type

- Aggregate Testing Equipment

- Application

- Aggregate strength and durability testing

- Max Height

- 400 mm

- Frequency

- 50 Hz

- Interface Type

- Direct / Panel

- Accuracy

- 1%

- Temperature

- 10C to 50C

- Specimen Size

- 40 mm to 70 mm aggregate

- Mounting Type

- Bench-top / Table-top

- Power Supply

- 230 V AC, 50 Hz

- Display Type

- Digital analog

- Humidity

- Up to 90% RH

- Number of Specimens

- Up to 4 drums in single machine

- Hardness

- Standard steel rollers

- Response Time

- Instant

- Features

- Corrosion-resistant, robust design, user-friendly

- Test Range

- Varies as per test type (e.g., crushing, abrasion)

- Resolution

- 0.01

- Usage

- Industrial testing laboratory

- Capacity

- 5 kg to 50 kg depending on accessory

- Machine Weight

- Approx. 45 kg

- Test Speed

- 60 rpm

- Control Mode

- Manual / Automatic

- Finish

- Powder coated

- Data Recording

- Manual log or printer option

- Accessories Included

- Measuring cylinder, tray, dust cover

- Noise Level

- < 75 dB

- Safety Features

- Overload protection, safety interlock

- Mobility

- Provided with castor wheels

- Drum Diameter

- 300 mm

- Construction Material

- Heavy duty steel

- Compliance

- IS:2386 (Part IV) and ASTM C131

Aggregate Testing Equipment Trade Information

- Payment Terms

- Telegraphic Transfer (T/T), Cheque

- Supply Ability

- 100 Per Day

- Delivery Time

- 1 Week

- Main Export Market(s)

- Australia, Asia

- Main Domestic Market

- All India

About Aggregate Testing Equipment

Aggregate Testing Equipment

All type AGGREGATE TESTING EQUIPMENT manufacturer and supplier.

Product details

| Material | Mild Steel |

| Usage/Application | Laboratory |

| Model Name/Number | EIE |

| Packaging Type | Wooden Box |

| Brand | EIE |

Reliable Aggregate Strength Testing

Designed for industrial laboratories, our equipment provides trustworthy results in aggregate strength and durability assessments. The machine supports various test types, including crushing and abrasion, with flexible capacities and specimen sizing. Its instant response digital analog display and precise manual or automatic data logging make operations efficient and straightforward.

Comprehensive Safety and Compliance

Prioritizing user safety, our equipment incorporates overload protection and a safety interlock, reducing risks during use. Manufactured with powder-coated heavy-duty steel, it complies with IS:2386 (Part IV) and ASTM C131, ensuring both national and international standards are met. The machines quiet operation (<75 dB) is ideal for busy testing environments.

Enhanced Mobility and User-Friendly Design

Mobility is effortless thanks to integrated castor wheels and bench-top mounting options. The equipments ergonomic layout, intuitive controls, and versatile automation grade facilitate smooth workflows. Accessories like measuring cylinders, trays, and dust covers optimize daily lab routines, while manual or printed data records meet documentation needs.

FAQs of Aggregate Testing Equipment:

Q: How does the Aggregate Testing Equipment ensure safety during operation?

A: This equipment features overload protection and a safety interlock system, which automatically halt operations if unsafe conditions are detected, preventing overloading and enhancing operator safety throughout testing.Q: What types of aggregate tests can be conducted with this equipment?

A: It accommodates a wide range of aggregate strength and durability tests, such as crushing and abrasion, conforming to IS:2386 (Part IV) and ASTM C131 standards. Test range and procedure vary depending on the test type selected.Q: When should I use manual log versus printer option for data recording?

A: You can record test data manually for smaller batches or less frequent use, while the printer option is ideal for high-throughput environments or when documented printouts of results are required for compliance or reporting purposes.Q: Where can this equipment be installed in a laboratory setting?

A: Its bench-top and table-top mounting options allow flexible placement in industrial testing laboratories. Castor wheels enhance mobility, making it easy to position next to other equipment or relocate as needed.Q: What is the recommended process for preparing aggregate specimens for testing?

A: Specimens should be sized between 40 mm and 70 mm, with capacities ranging from 5 kg to 50 kg depending on your selected accessory. The equipment can handle up to four drums simultaneously to expedite testing.Q: How does automated control benefit industrial users?

A: Automatic control enhances repeatability, reduces operator intervention, and streamlines test cycles. Users can select between manual and automatic modes for optimal workflow efficiency and consistent test outcomes.Q: What are the key benefits of using this aggregate testing equipment in my lab?

A: Key benefits include reliable test accuracy (1%) and instant results, robust and corrosion-resistant construction for longevity, safety-focused features, compliance with major standards, user-friendly data recording, and flexibility to adapt to various testing protocols.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Aggregate Testing Equipments Category

Jaw Crusher

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Application : Crushing of minerals, ores, and hard materials

Automation Grade : SemiAutomatic

Usage : Industrial

Product Type : Jaw crusher

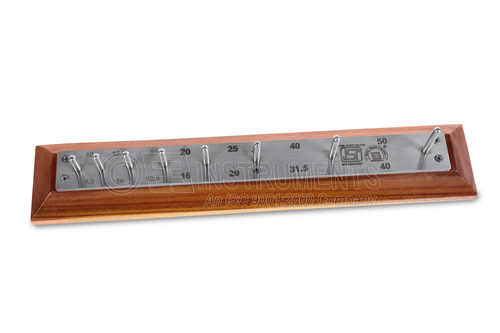

ISI Marked - Length Gauge

Price 3000 INR / Piece

Minimum Order Quantity : 1 Piece

Application : This instrument is used to determine the elongation index of aggregates

Automation Grade : Manual

Usage : Aggregate Testing Equipment

Product Type : ISI Marked Length Gauge

ISI Marked - Flakiness Gauge

Price 01 INR / Number

Minimum Order Quantity : 1 Piece

Application : Used to determine the percentage of particles in a coarse aggregate material that have a thickness (smallest dimension) of less than onehalf of the nominal size

Automation Grade : Manual

Usage : Aggregate Testing Equipment

Product Type : ISI Marked Flakiness Gauge

Los Angeles Abrasion Testing Machine

Minimum Order Quantity : 1 Piece

Application : This machine is used to find the percentage wear due to relative rubbing action between the aggregates and steel balls used as abrasive charge.

Automation Grade : Semi Automatic

Usage : Aggregate Testing Equipment

Product Type : Los Angeles Abrasion Testing Machine with Presettable Digital Counter

|

EIE INSTRUMENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry