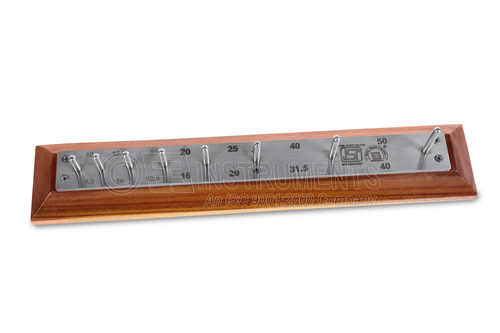

ISI Marked - Length Gauge

Price 3000 INR/ Piece

ISI Marked - Length Gauge Specification

- Number of Specimens

- As per IS standards

- Operating Voltage

- Not Applicable (Manual Operation)

- Test Range

- 6 mm to 80 mm

- Product Type

- ISI Marked - Length Gauge

- Application

- This instrument is used to determine the elongation index of aggregates

- Mounting Type

- Bench Top

- Power Supply

- Not Required (Non-Electric)

- Features

- Six hardened steel pins for aggregate measurement, ISI Marked, corrosion resistant

- Temperature

- Ambient

- Response Time

- Immediate (Manual)

- Automation Grade

- Manual

- Specimen Size

- Aggregate size 6.3mm to 50mm

- Accuracy

- High, as per ISI Standards

- Max Height

- Approx. 4 (as per product dimension)

- Resolution

- Up to 1 mm

- Measuring Range

- Specified by ISI Standards

- Hardness

- High-grade hardened steel pins

- Usage

- Aggregate Testing Equipment

- Dimension (L*W*H)

- 17X 3X 4 (L x W x H) Millimeter (mm)

- Capacity

- Single Specimen

- Machine Weight

- Approx. 1 kg

- Test Speed

- Manual

- Control Mode

- Manual

- Material

- Mild Steel Body with Hardened Steel Pins

- Finish Type

- Powder Coated

- Equipment Type

- ISI Marked - Length Gauge

- Pin Material

- Hardened & Ground Steel

- Marking

- ISI Marked body for quality assurance

- Color

- Blue/White (subject to availability)

- Packaging Type

- Box

ISI Marked - Length Gauge Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 200 Pieces Per Week

- Delivery Time

- 4 Week

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Box / Corrugated Box

- Certifications

- ISO 9001 : 2015

About ISI Marked - Length Gauge

Purpose:

This instrument is used to determine the elongation index of aggregates. Particle is elongated when its length (longest dimension) is more than 1.8 of the midsize of the sieve fraction.

Significance and Use:

This method classifies aggregate elongation by measuring the length of individual particles. The test is not applicable to material retained on a 63.0 mm BS test sieve.

Construction Details:

- ISI Marked

- Consists of a hard wood base with vertically mounted S.S. studs

- Eight S.S. studs are mounted.

- Aggregate to be classified is separated into seven sieve fractions from 63 to 6.3mm, and each fraction is examined separately.

- The mass of all elongated particles as percent of the sample is the elongation index.

- The distance between nails is applied according to following table.

Further details availableon our website.

The Price mentioned here are subject to change as per the capacity,specifications and application of the user.

Reliable Aggregate Testing Solution

Designed for precision, the ISI Marked Length Gauge is a dependable instrument for evaluating the elongation index of aggregates. Featuring a high-grade, powder-coated mild steel body and hardened steel pins, this tool aligns with specified Indian Standards, ensuring high accuracy and durability. Its simple, manual operation makes it a must-have for aggregate testing laboratories.

Durable and Corrosion-Resistant Design

Constructed with a strong mild steel body and fitted with six hardened steel pins, the length gauge offers excellent resistance to wear and corrosion. The powder-coated finish and ISI Marked assurance highlight quality and longevity, while its compact, bench-top design ensures easy integration in any lab environment.

Effortless Manual Operation

The ISI Marked Length Gauge operates manually, requiring no external power supply. Users can swiftly measure aggregates by simply placing specimens against the hardened steel pins. This manual control not only offers immediate results but also reduces maintenance, making the device ideal for routine testing applications.

FAQs of ISI Marked - Length Gauge:

Q: How is the ISI Marked Length Gauge used in aggregate testing?

A: The length gauge is used to determine the elongation index of coarse aggregates by manually passing individual particle sizes (6.3mm to 50mm) through slots defined by the hardened steel pins, as specified in ISI standards.Q: What are the benefits of using an ISI Marked Length Gauge?

A: The gauge offers high measurement accuracy, corrosion resistance due to its powder-coated body, immediate manual test results, and compliance with ISI standards for quality assurance, making it reliable for aggregate testing.Q: What materials are used in the construction of this length gauge?

A: The main body is manufactured from mild steel with a powder-coated finish, while the six measuring pins are made from hardened and ground steel for high durability and wear resistance.Q: Where is this equipment typically used?

A: The ISI Marked Length Gauge is primarily used in civil engineering, quality control laboratories, and material testing facilities engaged in aggregate analysis for construction projects.Q: What is the measuring capacity of the length gauge?

A: It is designed to measure individual aggregate specimens ranging from 6 mm up to 80 mm, but typically aligns with aggregate sizes from 6.3mm to 50mm as per ISI guidelines.Q: Is any external power or electrical supply required for operation?

A: No, the length gauge is entirely manual, requiring no electricity or external power, which facilitates easy use and immediate test results.Q: How does the ISI certification benefit users of this length gauge?

A: ISI marking signifies that the length gauge meets prescribed Indian Standards for accuracy, quality, and reliability, ensuring trustworthy results for aggregate elongation index testing.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

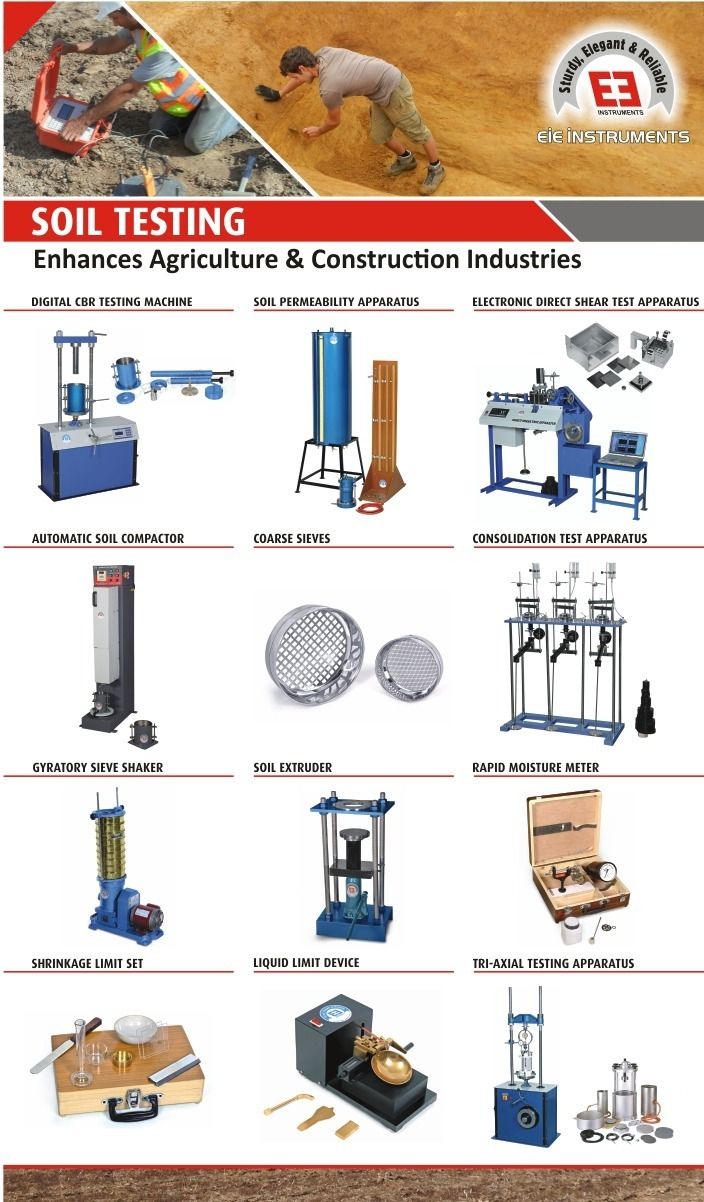

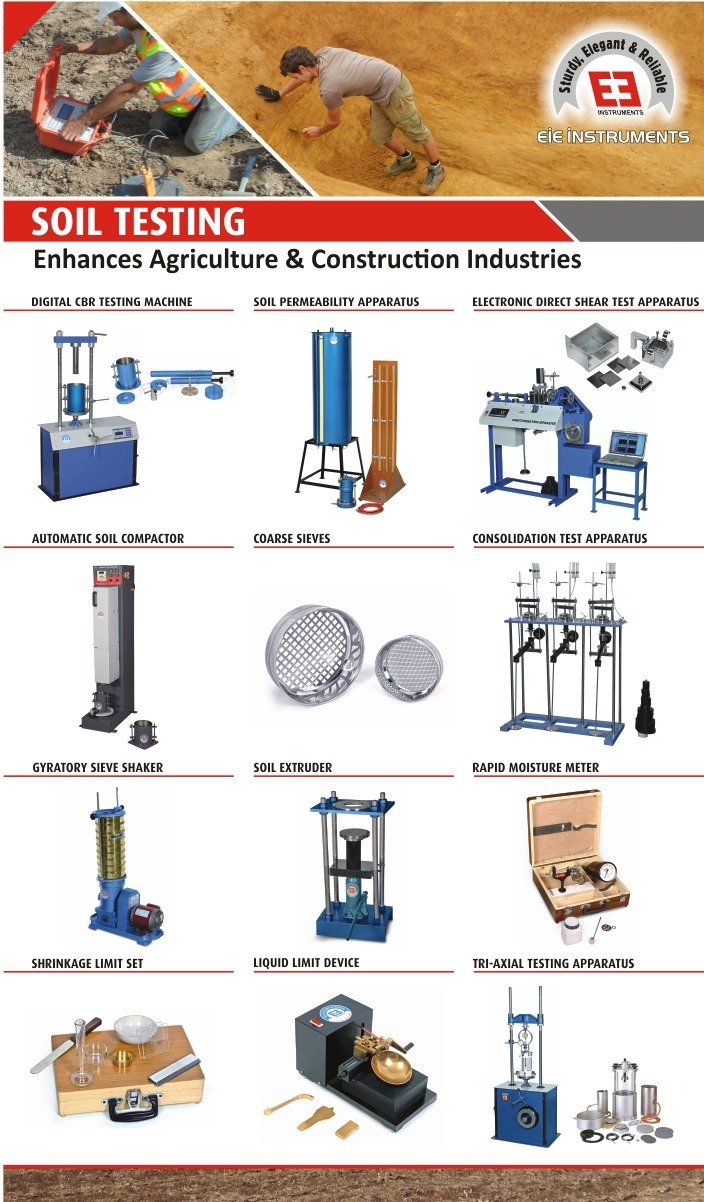

More Products in Aggregate Testing Equipments Category

Aggregate Testing Equipment

Price 1.00 INR / Piece

Minimum Order Quantity : 1

Usage : Industrial testing laboratory

Automation Grade : Automatic

Features : Corrosionresistant, robust design, userfriendly

Product Type : Aggregate Testing Equipment

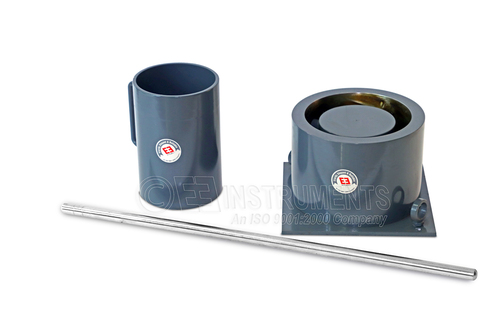

Aggregate Crushing Value Apparatus

Price 1.00 INR / Piece

Minimum Order Quantity : 1

Usage : Aggregate Testing Equipment

Automation Grade : Manual

Features : Rugged construction, corrosionresistant finish, easy to use

Product Type : AGGREGATE CRUSHING VALUE TEST APPARATUS

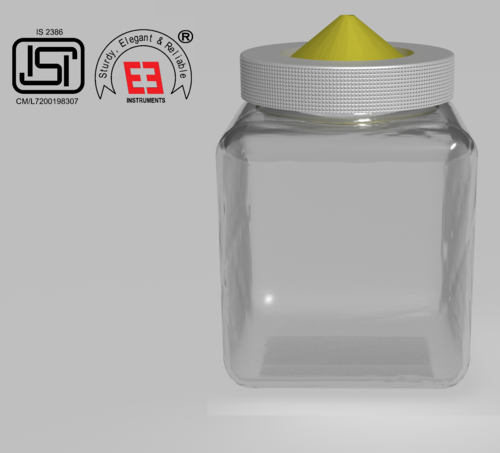

ISI Marked - Pycnometer Bottle

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Aggregate Testing

Automation Grade : Manual

Features : ISI Marked, with sealing cap and stopper

Product Type : Aggregate Testing Equipment

Los Angeles Abrasion Testing Machine

Minimum Order Quantity : 1 Piece

Usage : Aggregate Testing Equipment

Automation Grade : Semi Automatic

Features : Accurate results, Robust construction, Efficient working

Product Type : Los Angeles Abrasion Testing Machine with Presettable Digital Counter

|

EIE INSTRUMENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry