ACCELERATED AGGREGATE (ROADSTONE) POLISHING MACHINE

Price 1.00 INR/ Piece

ACCELERATED AGGREGATE (ROADSTONE) POLISHING MACHINE Specification

- Max Height

- Approx. 450 mm

- Power Supply

- 230 V AC, 50 Hz, Single Phase

- Features

- Heavy duty, low maintenance, corrosion resistant

- Automation Grade

- Semi-Automatic

- Number of Specimens

- 3 simultaneously

- Application

- Accelerated Polishing Machine. Specimens are manufactured in accurately machined and matched moulds; they are then removed from the moulds and located on the Road wheel.

- Measuring Range

- Highly polished to unpolished aggregates

- Frequency

- 50 Hz

- Interface Type

- Standard IEC

- Temperature

- 10C to 35C operating range

- Operating Voltage

- 230 V

- Accuracy

- 1% on speed

- Usage

- AGGREGATE TESTING EQUIPMENTS

- Test Range

- Up to 14 specimens

- Hardness

- High-grade steel construction

- Display Type

- Digital RPM display

- Port Size

- Standard interface for dust extraction

- Specimen Size

- 76 mm diameter x 25 mm thick

- Resolution

- 0.1 rpm

- Humidity

- Operates in 20%80% RH

- Mounting Type

- Floor Mounted

- Product Type

- ACCELERATED AGGREGATE (ROADSTONE) POLISHING MACHINE

- Equipment Type

- Roadstone Polishing Testing Machine

- Response Time

- Immediate

- Capacity

- 14 specimens per set

- Machine Weight

- Approx. 95 kg

- Test Speed

- 315 10 rpm

- Test Width

- 38 mm

- Test Stroke

- Variable, up to 400 mm

- Control Mode

- Manual / Automatic

- Wheel Material

- Cast Aluminium with resilient rubber covering

- Protective Guard

- Full transparent shield

- Noise Level

- < 70 dB(A)

- Abrasive Feed System

- Automatic Quartz Sand Dispenser

- Safety Mechanism

- Emergency stop push button

- Motor Power

- 0.5 HP

- Standard Compliances

- BS 812: Part 114, ASTM and EN standards

ACCELERATED AGGREGATE (ROADSTONE) POLISHING MACHINE Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 100 Pieces Per Month

- Delivery Time

- 4 Week

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Box / Corrugated Box

- Certifications

- ISO 9001 : 2015

About ACCELERATED AGGREGATE (ROADSTONE) POLISHING MACHINE

Details

Accelerated Polishing Machine. Specimens are manufactured in accurately machined and matched moulds, they are then removed from the moulds and located on the Road wheel. Abrasives are continuously fed through fixed speed mechanical feeders. Flour emery is loaded on to the tyred wheel by spring loaded separator plate; corn emery is fed directly to the specimen through a feed chute. Water is introduced at a controlled rate from a self contained water supply. Used water and abrasives are collected in a removable tray. The tyred wheel is raised and lowered to the road wheel by a mechanical lifting device, these wheels are easily changed. The road wheel having a flat periphery, and revolving about its on axis. Rubber tyred wheel of 20cms dia and 5cms breadth to bear on the stone surface of the road wheel a total load of 40 Kg.

ADDITIONAL ESSENTIAL ACCESSORIES REQUIRED FOR THE TEST

1.Skid resistance tester to be purchased at additional cost

2. Specimen preparation moulds

3. silicon sand

4. Air floated emery powder

Furtherdetails available on our website.

The Price mentioned here are subject to change as per the capacity,specifications and application of the user.

Accurate Aggregate Polishing Assessment

Engineered for standardized testing, this machine determines the polishing resistance of roadstones tailored to various international standards like BS 812: Part 114, ASTM, and EN. The precise, heavy-duty design and high-grade steel build ensure reliable, repeatable results for laboratory and quality control environments.

Comprehensive Safety and Control

Equipped with a full transparent guard and emergency stop push button, operator safety is maximized during use. The noise level remains below 70 dB(A) for comfortable laboratory conditions, while advanced controls and a digital RPM display provide real-time feedback, further enhancing control and test accuracy.

FAQs of ACCELERATED AGGREGATE (ROADSTONE) POLISHING MACHINE:

Q: How is the Accelerated Aggregate (Roadstone) Polishing Machine operated?

A: The machine operates in manual or automatic mode using a digital RPM display for speed monitoring. The abrasive feed is managed by an automatic quartz sand dispenser, and the system is activated using standard power supply. Safety is ensured with a transparent guard and an emergency stop button.Q: What specimens can be tested with this machine?

A: This equipment is designed for aggregate specimens measuring 76 mm in diameter and 25 mm in thickness. Up to three specimens can be polished simultaneously, with the capacity to test up to 14 specimens per set, covering a broad measurement range from highly polished to unpolished aggregates.Q: When should I use the Accelerated Aggregate Polishing Machine in aggregate testing?

A: This machine is used during the aggregate testing phase where the assessment of surface polishing resistance is required, particularly for materials intended for use in roadways. It is essential when evaluating the durability of aggregates against polishing for construction and research purposes.Q: Where can this polishing machine be installed and operated?

A: The machine is floor mounted, suitable for laboratory environments. It operates reliably within 10C to 35C and 20%80% relative humidity, making it ideal for most quality control labs, educational institutions, and research facilities.Q: What is the process for preparing and loading specimens?

A: Specimens are manufactured using accurately machined and matched moulds. After removing them from the moulds, they are positioned on the Road wheel of the machine. The machine then subjects them to automatic abrasive feeding and controlled rotation for consistent polishing.Q: How does this equipment benefit aggregate testing?

A: The polishing machine ensures high accuracy (1% on speed), repeatability, and ease-of-use with low maintenance. Compliance with international standards and advanced safety features ensure reliable data, improved laboratory safety, and better decision-making for roadstone applications.Q: What maintenance is required for long-term operation?

A: Routine cleaning, regular checks of the abrasive feed system, and periodic inspection of safety mechanisms are recommended. The machine is designed for low maintenance, with corrosion-resistant parts and accessible controls to support long-term, trouble-free use.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

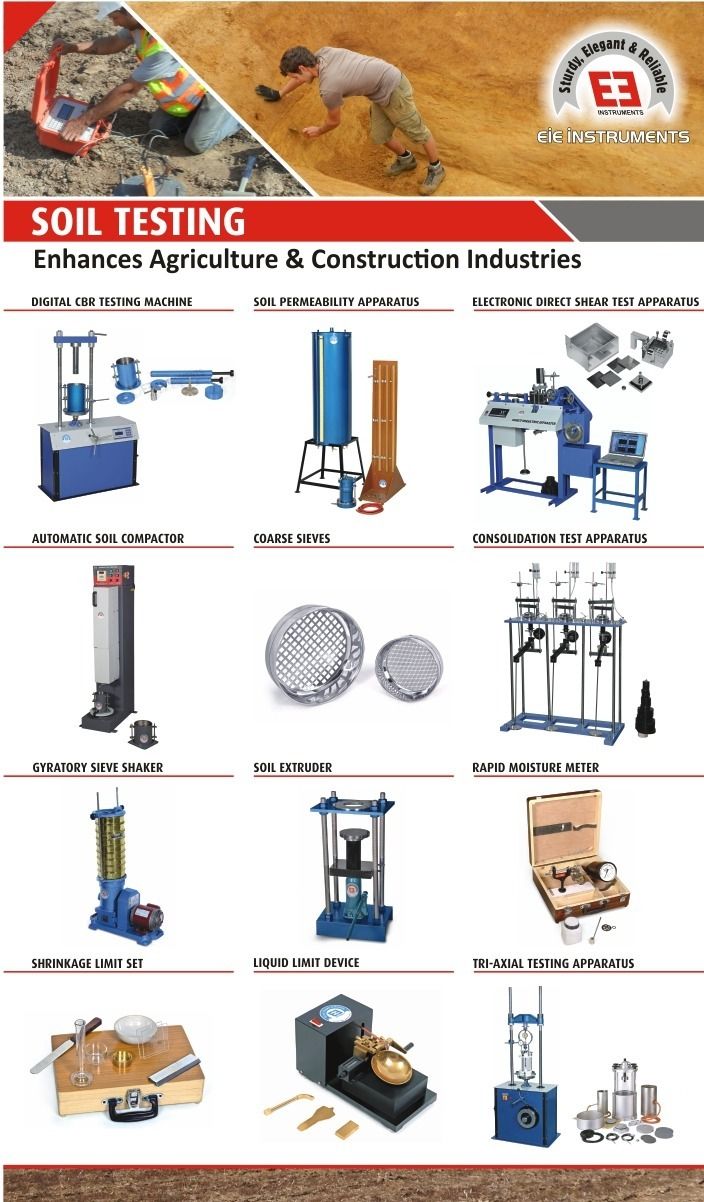

More Products in Aggregate Testing Equipments Category

Aggregate Testing Equipment

Price 1.00 INR / Piece

Minimum Order Quantity : 1

Product Type : Aggregate Testing Equipment

Features : Corrosionresistant, robust design, userfriendly

Automation Grade : Automatic

Usage : Industrial testing laboratory

ISI Marked - Bulk Density Cylindrical Metal Measure

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : Bulk Density Cylindrical Metal Measure for Aggregate

Features : ISI Marked, Smooth Finish, Handles Provided, Corrosion Resistant

Automation Grade : Manual

Usage : Aggregate Testing Equipment

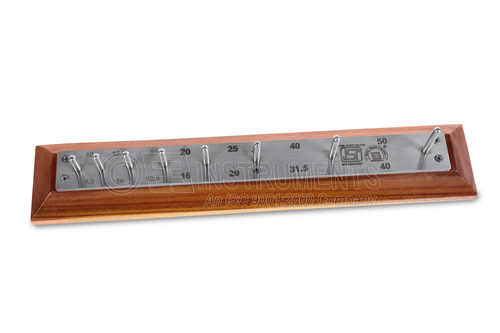

ISI Marked - Length Gauge

Price 3000 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : ISI Marked Length Gauge

Features : Six hardened steel pins for aggregate measurement, ISI Marked, corrosion resistant

Automation Grade : Manual

Usage : Aggregate Testing Equipment

Aggregate Impact Testing Machine

Minimum Order Quantity : 1 Piece

Product Type : Aggregate Impact Testing Machine

Features : Accurate results, Robust construction, Efficient working

Automation Grade : Automatic

Usage : Aggregate impact value gives a relative measure of the resistance of an aggregate to sudden shock or impact, which in some aggregates differs from its resistance to a slow compressive load.

|

EIE INSTRUMENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry