Shear Bond Jig-Compression Method

Shear Bond Jig-Compression Method Specification

- Application

- Shear Bond Jig tests for the shear strength test of dry-set cement mortar (Cemntitious Mortar)

- Color

- Silver

- Usage

- Tile Adhesive Testing

- Features

- Accurate results, Robust construction, Efficient working

- Material

- Steel

- Product Type

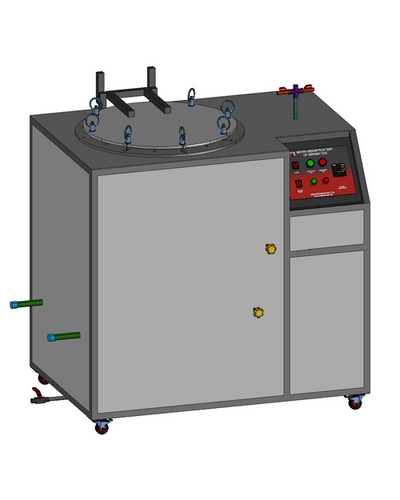

- Shear Bond Jig-Compression Method

- Weight

- 13 to 15 Kilograms (kg)

- Machine Weight

- 13 to 15 Kilograms (kg)

- Control Mode

- Manual

Shear Bond Jig-Compression Method Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 100 Pieces Per Month

- Delivery Time

- 4 Week

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Box / Corrugated Box

- Certifications

- ISO 9001 : 2015

About Shear Bond Jig-Compression Method

Applications:

Shear Bond Jig tests for the shear strength test of dry set cement mortar (CementitiousMortar)

Principle:

For this test, the dryset mortar samples are stressed in shear compression to failure using a compression test machine paired with a shear bond jig. The sample is clamped in the vice jig and tested according to the standard procedure.

Details:

- Jaws are adjustable

- Fabricated from Steel Material

- Supplied complete with upper compression plate

Furtherdetails available on our website.

The Price mentioned here are subject to change as per the capacity,specifications and application of the user.

Engineered for Accurate Tile Adhesive Testing

The SHEAR BOND JIGCOMPRESSION METHOD offers a standardized approach to evaluating the shear strength of cement-based mortars used in tile installations. Designed for rigorous testing environments, the jig delivers consistency and reliability, aiding professionals in meeting quality benchmarks for construction materials. Its robust build ensures lasting performance even under frequent use.

Precision and Durability in Material Analysis

Crafted entirely from sturdy steel, the jig can withstand the demands of repetitive laboratory testing. Its 1315 kg weight provides stability during compression, resulting in accurate and reproducible results. As a key instrument for manufacturers, exporters, and service providers, the SHEAR BOND JIG safeguards both efficiency and safety in adhesive testing protocols.

FAQs of SHEAR BOND JIG-COMPRESSION METHOD:

Q: How is the SHEAR BOND JIGCOMPRESSION METHOD used in tile adhesive testing?

A: This jig is used to assess the shear strength of dry-set cement mortar by applying a controlled compressive force to a sample. The method helps evaluate the bonding quality of tile adhesives and mortars, ensuring they meet industry standards.Q: What materials can be tested with the SHEAR BOND JIG?

A: The jig is designed for testing dry-set cementitious mortar, widely used in tile adhesive applications. It is suitable for both standard laboratory samples and on-site quality checks in construction projects.Q: When should I use the SHEAR BOND JIG for my construction materials?

A: Use the SHEAR BOND JIG whenever you need to verify the shear bonding strength of tile adhesives or to ensure mortar quality during material development and before or after installation of tiles.Q: Where is the SHEAR BOND JIGCOMPRESSION METHOD typically utilized?

A: This testing apparatus is commonly used in material testing laboratories, quality control departments of tile adhesive manufacturers, and research facilities focused on construction materials.Q: What is the process of testing shear strength with this jig?

A: A prepared mortar sample is secured in the jig, which then applies a compressive force to induce shearing. The resulting data measures the strength of the bond, helping determine if the adhesive meets required specifications.Q: What are the benefits of using the SHEAR BOND JIGCOMPRESSION METHOD?

A: Using this jig provides accurate, repeatable testing of mortar bond strength, ensuring higher quality and reliability of tile adhesives. It supports compliance with industry standards and helps improve construction quality overall.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Tiles and Ceramic Testing Equipments Category

MOR Testing Machine for Green/Fired Ceramic Bar

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Power Supply : AC 220V, 50 Hz

Automation Grade : Semiautomatic

Frequency : 50 Hz

Features : Automatic data recording; overload protection; userfriendly operation

WATERBATH FOR WATER ABSORPTION TEST OF CERAMIC TILE

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Power Supply : 220V AC, 50Hz, Single Phase

Automation Grade : Manual / Semiautomatic

Frequency : 50 Hz

Features : Inbuilt vacuum pump, Digital temperature control, Corrosionresistant stainless steel tank, Slot arrangement for vertical placement of tiles

SHEAR BOND JIG-TENSILE METHOD

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Power Supply : 230V AC, 50Hz

Automation Grade : Manual / Semiautomatic

Frequency : 50 Hz

Features : Corrosionresistant, Easy operation, Sturdy design

Dilatometer (Determination of Linear Thermal Expansion)

Minimum Order Quantity : 1 Piece

Power Supply : 240 Volts, 50/60 Hz Single Phase, AC Supply

Automation Grade : Semi Automatic

Frequency : 5060 Hertz (HZ)

Features : Accurate results, Robust construction, Efficient working

|

EIE INSTRUMENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry