MOR Testing Machine for Green/Fired Ceramic Bar

Price 1.00 INR/ Piece

MOR Testing Machine for Green/Fired Ceramic Bar Specification

- Port Size

- Custom or as per requirement

- Voltage

- 220 Volt (v)

- Gas Pressure

- N/A (not applicable)

- Number of Specimens

- 1 per test cycle

- Features

- Automatic data recording; overload protection; user-friendly operation

- Max Height

- 200 mm (specimen clearance)

- Measuring Range

- 0 - 2,000 kgf

- Humidity

- Up to 85% RH

- Product Type

- Tiles and Ceramics Testing Machine

- Temperature

- Room temperature (10C - 40C)

- Hardness

- Tested as per MOR procedure

- Automation Grade

- Semi-automatic

- Interface Type

- USB/RS232 (optional)

- Display Type

- Digital LCD

- Test Range

- 0 - 2000 kgf

- Accuracy

- 0.5%

- Power Supply

- AC 220V, 50 Hz

- Frequency

- 50 Hz

- Operating Voltage

- 220V AC

- Response Time

- < 10 ms

- Specimen Size

- 150 mm x 25 mm x 10 mm (standard bar)

- Mounting Type

- Floor Mounted

- Application

- Suitable to test Fired & Green ceramic Tile/Bar on the same machine

- Resolution

- 0.1 kgf

- Usage

- MOR (Modulus of Rupture) test for ceramic bars or tiles

- Capacity

- Up to 2000 kgf

- Machine Weight

- Approx. 240 kg

- Test Speed

- 0.05 - 5 mm/min (adjustable)

- Test Width

- Up to 100 mm

- Test Stroke

- Up to 80 mm

- Control Mode

- AC Variable Frequency Drive with AC Induction Motor

- Equipment Type

- Tiles and Ceramics Testing Machine

- Load Cell Type

- High Precision Strain Gauge Type

- Standards

- Complies with ASTM C1161, ISO 14704

- Data Output

- PC Connectivity, Printer Port

- Safety Features

- Emergency Stop, Mechanical Overload Protection

- Structure Material

- Mild Steel Frame with Powder Coating

MOR Testing Machine for Green/Fired Ceramic Bar Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 100 Pieces Per Month

- Delivery Time

- 4 Week

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Box / Corrugated Box

- Certifications

- ISO 9001 : 2015

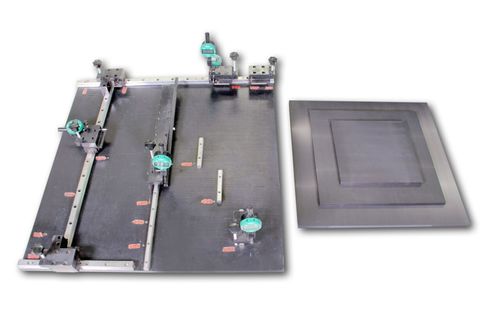

About MOR Testing Machine for Green/Fired Ceramic Bar

Salient Features:

- Suitable to test Fired & Green ceramic Tile and Bar on the same machine

- Supplied with 2 different flexible platform and dedicated load cells

- Both the platforms can be interchangeable as and when required.

- Suitable for quiet and vibration free operations

- Direct reading possible for different shapes of tiles (Square, Rectangular and Round)

- Supplied with sample platform of 30 x 30 cm size and dedicated load cell

- Digital Model with LCD Display for easy readability

- Back light to observe the readings even in dark.

- Direct Display of Load and Collapsing Force/MOR Value/Breaking strength value.

- Auto reverse facility upon sample failure

Furtherdetails available on our website.

The Price mentioned here are subject to change as per the capacity,specifications and application of the user.

Precision Testing for Ceramic Materials

This MOR Testing Machine enables high accuracy measurement of rupture modulus for both fired and green ceramic tiles or bars. Using a semi-automatic control system and high precision strain gauge load cell, it delivers repeatable and reliable results for research and quality assurance applications. The digital LCD ensures clear readings while advanced safety features protect users and samples.

Versatile Operation and Connectivity

With its adjustable test speed and stroke, the machine caters to diverse ceramic testing needs. It provides seamless data output to PCs via USB or RS232 interfaces and supports printer connectivity for instant documentation. The floor-mounted design ensures stability during testing, and custom port sizes allow flexibility based on user requirements.

Compliance and Safety Assured

Built in accordance with ASTM C1161 and ISO 14704 standards, this machine integrates safety mechanisms such as emergency stop and mechanical overload protection. Automatic data recording enhances traceability and reduces errors, making it an optimal solution for ceramic product manufacturers, exporters, and research facilities.

FAQs of MOR Testing Machine for Green/Fired Ceramic Bar:

Q: How does the MOR Testing Machine perform modulus of rupture tests on ceramic bars or tiles?

A: The machine employs a high precision strain gauge type load cell to apply and measure force on the ceramic specimen, which is then translated into modulus of rupture values. Its semi-automatic operation and adjustable test speed allow for controlled and accurate testing as per established standards.Q: What types of ceramic specimens can be tested using this equipment?

A: This machine is suitable for both fired and green ceramic tiles or bars, accommodating standard specimen sizes of 150 mm x 25 mm x 10 mm. It supports a single specimen per test cycle and can test widths up to 100 mm and strokes up to 80 mm.Q: When is it beneficial to use PC connectivity and printer port features on this testing machine?

A: PC connectivity (via USB/RS232) and printer port use are advantageous for automatic data recording, generating instantaneous test reports, and facilitating efficient documentation, particularly when multiple tests are conducted for quality control or research purposes.Q: Where can this MOR Testing Machine be installed for optimal performance?

A: Designed for floor mounting, the machine performs best in laboratory, manufacturing, or research environments where stable, vibration-free floors are available. Its dimensions and weight (approximately 240 kg) ensure rigidity and minimize disturbance during operation.Q: What is the process for conducting a test using the MOR machine?

A: Start by placing the prepared ceramic specimen in the machine, set the desired test parameters (speed, stroke), and initiate the test. The machine applies force until rupture, with real-time data displayed on the digital LCD and recorded automatically. Safety features, including overload protection and emergency stop, ensure secure operation throughout testing.Q: How does this equipment contribute to ceramic product quality assurance?

A: By providing precise, standard-compliant rupture strength data for both fired and green ceramics, the machine helps manufacturers verify product durability. The accuracy (0.5%) and fast response ensure reliable quality checks, thereby improving consistency and reducing the risk of failure in end-use applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Tiles and Ceramic Testing Equipments Category

Portable Gauge

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Features : Lightweight, ergonomic, rechargeable, data hold

Automation Grade : Manual

Usage : Inspection, measurement

M.O.R. Testing Machine

Price 1.00 INR

Minimum Order Quantity : 1 Piece

Features : Heavyduty steel frame, Overload Protection, Adjustable Traverse Speed

Automation Grade : SemiAutomatic/Manual

Usage : Industrial

Product Type : M.O.R. Testing Machine

Manual Universal Gauge

Minimum Order Quantity : 1 Piece

Features : Accurate results, Robust construction, Efficient working

Automation Grade : Manual

Usage : Laboratory

Product Type : Manual Universal Gauge

Determination of Resistance to Thermal Shock

Minimum Order Quantity : 1 Piece

Features : Accurate results, Robust construction, Efficient working

Automation Grade : Semi Automatic

Usage : Industrial

Product Type : DETERMINATION OF RESISTANCE TO THERMAL SHOCK

|

EIE INSTRUMENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry