SHEAR BOND JIG-TENSILE METHOD

Price 1.00 INR/ Piece

SHEAR BOND JIG-TENSILE METHOD Specification

- Usage

- Tile Adhesive Testing

- Automation Grade

- Manual / Semi-automatic

- Power Supply

- 230V AC, 50Hz

- Max Height

- 200 mm

- Test Range

- 0 - 5 kN

- Response Time

- <1 s

- Accuracy

- 1% of reading

- Resolution

- 0.01 kN

- Humidity

- Up to 85% RH

- Interface Type

- USB/RS232

- Measuring Range

- 0 - 5 kN

- Frequency

- 50 Hz

- Number of Specimens

- 1 at a time

- Product Type

- SHEAR BOND JIG-TENSILE METHOD

- Mounting Type

- Tabletop

- Temperature

- Up to 40C

- Display Type

- Digital

- Application

- Shear Bond Jig tests for the shear strength test of dispersion adhesives

- Operating Voltage

- 230V AC

- Features

- Corrosion-resistant, Easy operation, Sturdy design

- Specimen Size

- 100 x 100 mm (Customizable)

- Capacity

- Up to 5 kN

- Machine Weight

- Approx. 8 kg

- Test Speed

- 0.5 - 500 mm/min

- Test Width

- 50 mm

- Test Stroke

- 150 mm

- Control Mode

- Manual / Motorized

- Operation Environment

- Laboratory / Field

- Sample Clamping

- Quick-Release Clamps

- Fixture Material

- Stainless Steel or Mild Steel

- Finish

- Powder Coated Body

- Safety Features

- Overload Protection

- Equipment Type

- SHEAR BOND JIG-TENSILE METHOD

- Load Cell Type

- Strain Gauge Based

- Calibration

- Supplied with Calibration Certificate

SHEAR BOND JIG-TENSILE METHOD Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 100 Pieces Per Month

- Delivery Time

- 4 Week

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Box / Corrugated Box

- Certifications

- ISO 9001 : 2015

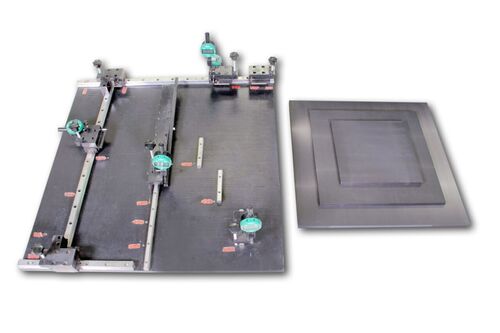

About SHEAR BOND JIG-TENSILE METHOD

Applications:

Shear Bond Jig tests for the shear strength test of dispersion adhesives

Details:

- The jig is constructed from 6 X 6 mm M.S frame

- Sample size is 108 X 108 X 6.5 mm sample

Further details availableon our website.

The Price mentioned here are subject to change as per the capacity,specifications and application of the user.

Advanced Shear Bond Testing for Adhesive Reliability

Evaluate the shear bond strength of dispersion adhesives with utmost precision using our SHEAR BOND JIGTENSILE METHOD. Designed for both laboratory and onsite field use, this equipment offers quick sample mounting, customizable specimen sizing, and robust overload protection. Its digital interface ensures accurate readings, while the corrosion-resistant body guarantees longevity. With manual or semi-automatic operation, it suits a wide range of adhesive testing needs, particularly tile adhesives.

Efficient and User-Friendly Operation

Thanks to its quick-release clamps and intuitive design, setting up specimens is fast and hassle-free. The strain gauge-based load cell delivers reliable measurement across a 05 kN range, with high resolution and quick response. Overload protection and a supplied calibration certificate ensure safety and accuracy, while the devices tabletop mounting makes it easily deployable in various environments.

FAQs of SHEAR BOND JIG-TENSILE METHOD:

Q: How does the SHEAR BOND JIGTENSILE METHOD operate for adhesive testing?

A: The device utilizes quick-release clamps to secure specimens, then applies a controlled tensile force using a strain gauge-based load cell. Measurements are digitally displayed, ensuring accuracy and rapid results for assessing shear bond strength in dispersion adhesives.Q: What types of adhesives and specimens can be tested with this equipment?

A: It is specifically designed for shear strength tests of dispersion adhesives, commonly used in tile adhesive applications. Specimen sizes are customizable, with the standard size being 100 x 100 mm, making it highly versatile for different testing needs.Q: When should calibration be performed on the machine?

A: Calibration is crucial before initial use and at regular intervals depending on the frequency of testing. Each unit is supplied with a calibration certificate to guarantee accuracy up to 1% of the reading.Q: Where can the SHEAR BOND JIGTENSILE METHOD be used?

A: This equipment is suitable for both laboratory and field environments. Its compact tabletop design allows easy setup in research labs, quality control rooms, or onsite at construction locations.Q: What process is involved in conducting a shear bond test using this equipment?

A: Users mount the specimen via quick-release clamps, select control mode (manual or motorized), and initiate the test. The device applies force at a chosen speed until shear failure occurs, recording precise data for analysis.Q: What benefits does this machine offer to manufacturers and researchers?

A: Users gain reliable, repeatable results for adhesive quality assurance, thanks to the machines precise load control, digital measurement, corrosion resistance, and overload safety. Its ideal for benchmarking adhesive strength and optimizing product formulations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Tiles and Ceramic Testing Equipments Category

BULK DENSITY APPARATUS - MERCURY METHOD

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Features : Nondestructive, accurate, easy to use; special safety enclosure for mercury handling

Application : We present a measuring system for the strength of unfired ceramic materials and in particular pressed tiles.

Automation Grade : Manual

Usage : Tiles and Ceramics Testing Equipment

Universal Gauge - Plucometer

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Features : Robust construction, easy to use, portable

Application : APP FOR MEASUREMENT OF SURFACE FLATNESS AND WARPAGE

Automation Grade : Manual

Usage : TILES AND CERAMICS TESTING EQUIPMENTS

Determination of Resistance to Thermal Shock

Minimum Order Quantity : 1 Piece

Features : Accurate results, Robust construction, Efficient working

Application : Determination of resistance to thermal shock of a whole tile by cycling 10 times between the temperatures of cold water and a temperature just above that of boiling water. Usually tests are carried out between 15 C and 145 C.

Automation Grade : Semi Automatic

Usage : Industrial

Fully Automatic Universal Gauge

Minimum Order Quantity : 1 Piece

Features : Accurate results, Robust construction, Efficient working

Application : Industrial

Automation Grade : Semi Automatic

Usage : Laboratory

|

EIE INSTRUMENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry