Universal Gauge - Plucometer

Price 1.00 INR/ Piece

Universal Gauge - Plucometer Specification

- Test Range

- 0-10 mm

- Interface Type

- Digital Gauge Interface

- Automation Grade

- Manual

- Display Type

- Digital

- Temperature

- Operating range 10C to 40C

- Response Time

- Instant

- Measuring Range

- 0-10 mm

- Power Supply

- No power required (Manual Operation)

- Product Type

- Universal Gauge - Plucometer - With Digital Gauges

- Specimen Size

- Applicable for different tile sizes

- Application

- APP FOR MEASUREMENT OF SURFACE FLATNESS AND WARPAGE

- Max Height

- Approx. 150 mm (customizable)

- Number of Specimens

- Single specimen at a time

- Resolution

- 0.01 mm

- Accuracy

- 0.01 mm

- Operating Voltage

- Manual, No voltage required

- Features

- Robust construction, easy to use, portable

- Usage

- TILES AND CERAMICS TESTING EQUIPMENTS

- Mounting Type

- Free standing

- Humidity

- Standard Laboratory Conditions

- Machine Weight

- Approx. 20 kg

- Test Speed

- Manual

- Test Width

- Up to 600 mm

- Test Stroke

- Adjustable

- Control Mode

- Manual

- Equipment Type

- Universal Gauge - Plucometer

- Digital Gauge Battery

- Standard 1.5V (LR44) replaceable battery

- Surface Finish

- Corrosion resistant, powder coated

- Frame Material

- Stainless steel with precision ground base

- Calibration

- Supplied with calibration certificate

- Portability

- Lightweight and easily transportable

- Gauge Indicator Type

- High precision digital gauge with LCD display

- Alignment

- Adjustable arms for specimen placement and leveling

Universal Gauge - Plucometer Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 100 Pieces Per Month

- Delivery Time

- 4 Week

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Box / Corrugated Box

- Certifications

- ISO 9001 : 2015

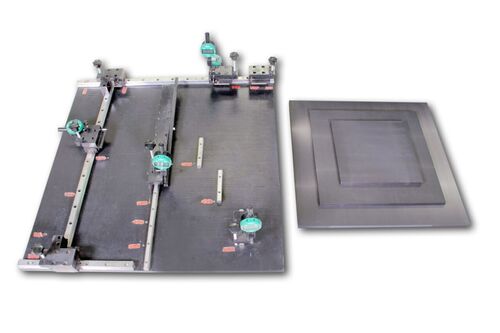

About Universal Gauge - Plucometer

Application :

- For measurement of straightness and squareness.

- For measurement of flatness and warp age

- Tiles size: 100 x 100mm to 600 x 600mm

- Material of Construction: Mild steel duly powder coated

Procedure for Measurement of Straightness of tiles:

- Apparatus should be such that, when a tile is placed in the apparatus, the locating studs are 5 mm from each corner of side being measured.

- Fit the appropriate calibrating plate exactly into the position into the instrument and adjust the dial gauge readings to a suitable known value.

- Remove the calibrating plate.

- Place the proper surface of the tile on the locating studs in the apparatus.

- Now, record the dial gauge readings in the center of the side.

- Rotate the tile, if it is square, to obtain four different measurements.

- Repeat this procedure for each tile.

- The average value of the deviation is calculated for each tile as well as the average value of the average deviations of 10 tiles is also calculated.

Procedure for measurement of squareness:

- Apparatus should be such that, when a tile is placed in the apparatus, the locating studs are 5 mm from each corner of side adjacent to the side being measured.

- The plunger of the dial gauge shall also be 5 mm from the corner of the tile on the side being measured.

- Fit the appropriate calibrating plate exactly into the position into the instrument and adjust the dial gauge readings to a suitable known value.

- Remove the calibrating plate.

- Place the proper surface of the tile on the locating studs in the apparatus.

- Now, record the dial gauge readings 5 mm from the corner.

- Rotate the tile, if it is square, to obtain four different measurements.

- Repeat this procedure for each tile.

- The average value of the deviation is calculated for each tile as well as the average value of the average deviations of 10 tiles is also calculated.

Procedure for measuring Surface Flatness:

- Select an apparatus of appropriate size and place the corresponding calibrating plate exactly into position on top of the three accurately positioned studs.

- The centre of each stud is 10 mm from the side of the tile and two outer dial gauges are 10 mm from the sides of the tile.

- Adjust the three dial gauges to suitable known value.

- Remove the calibrating plate.

- Place a tile on the apparatus with the glaze or proper surface downwards, and record the three dial gauge readings.

- Rotate the tile, if it is square, to obtain four different measurements.

- Repeat this procedure for each tile.

Also available in various sizes measurement of surface flatness warpage : 600 x 600 MM, 800 x 800 MM, 800 x 1200 MM, 1000 x1000 MM, 1200x1200 MM

Further details availableon our website.

The Price mentioned here are subject to change as per the capacity,specifications and application of the user.

Exceptional Precision and Reliability

Featuring a high-precision digital gauge with an accuracy of 0.01 mm and instant response time, the Universal Gauge - Plucometer ensures dependable measurement for surface flatness and warpage. Each unit is delivered with a calibration certificate, providing users with utmost confidence in their test results.

Versatility and Ease of Use

Designed to handle a wide array of tile and ceramic specimen sizes, this gauging tool boasts adjustable arms and an ergonomic, manual control mode. Its lightweight frame, robust construction, and simple operation make it suitable for both laboratory and field uses, supporting test widths of up to 600 mm.

Durable Construction and Portability

Manufactured from stainless steel and finished with a corrosion-resistant powder coating, the device ensures durability and longevity, even in challenging conditions. Weighing approximately 20 kg and featuring a portable design, it can be transported and set up with minimal effort, facilitating seamless quality control.

FAQs of Universal Gauge - Plucometer:

Q: How does the Universal Gauge - Plucometer measure surface flatness and warpage?

A: The Universal Gauge - Plucometer uses a high-precision digital gauge with an LCD display to measure deviations in flatness and warpage. Its adjustable arms help align and level the specimen, allowing it to accurately record measurements within a range of 0-10 mm.Q: What materials and specimens can be tested using this device?

A: This equipment is primarily used for testing tiles and ceramics, accommodating a range of specimen sizes up to 600 mm wide and a maximum height of approximately 150 mm. Its robust stainless steel construction and adjustable configuration support various applications in tile and ceramic assessment.Q: When should calibration be performed on the Plucometer?

A: The Universal Gauge - Plucometer is supplied pre-calibrated with a calibration certificate. For optimal accuracy, regular verification is recommended as per your laboratorys quality control standards or after extended periods of use or transport.Q: Where is this equipment best utilized?

A: It is ideally suited for standard laboratory conditions but is also portable enough for on-site use. Its corrosion-resistant construction and lightweight design make it practical for both controlled environments and field testing scenarios.Q: What is the process of setting up and using the Universal Gauge - Plucometer?

A: To use the device, place the specimen on the precision-ground base, adjust the arms for proper alignment, and use the manual controls to measure surface flatness and warpage. The digital gauge provides instant and accurate readings on the LCD display.Q: What are the main benefits of using this Universal Gauge - Plucometer?

A: Users benefit from high accuracy, instant digital readouts, versatility in specimen size, lightweight portability, and no reliance on external power sources. The corrosion-resistant build adds durability for long-term, reliable application in multiple testing environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Tiles and Ceramic Testing Equipments Category

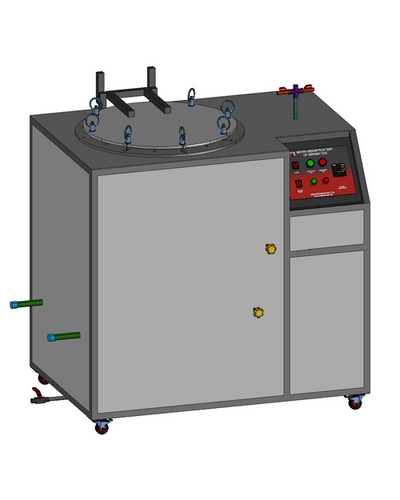

WATERBATH FOR WATER ABSORPTION TEST OF CERAMIC TILE

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Automation Grade : Manual / Semiautomatic

Features : Inbuilt vacuum pump, Digital temperature control, Corrosionresistant stainless steel tank, Slot arrangement for vertical placement of tiles

Usage : Tiles and Ceramics Testing Equipment

Application : For water absorption test of ceramic tiles. The tiles will be placed vertically in the slots provided to conduct the water absorptions characteristic test.

Density Cup S.S.

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Automation Grade : Manual

Features : Corrosion resistant, sturdy, mirror polished

Usage : Industrial

Application : For accurate determination of paint, ink, and other liquid densities

Skid Resistance Tester

Minimum Order Quantity : 1 Piece

Automation Grade : Semi Automatic

Features : Accurate results, Robust construction, Efficient working

Usage : Used to measure the resistance value of the asphalt pavement marking, stone etc.

Application : The instrument is used to measure the resistance value of the asphalt pavement marking, stone, or other material (specimen) and to assess antisliding ability of the road and the road surface material (specimen) in wet or humid conditions. Used to determine friction coefficient on flat, cambered or gradient road surface like highway pavement, city road pavement, airport track.

Rapid Pot Mill

Minimum Order Quantity : 1 Piece

Automation Grade : Semi Automatic

Features : Accurate results, Robust construction, Efficient working

Usage : Laboratory

|

EIE INSTRUMENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry