Riffle Sample Divider

Price 7280.00 INR/ Piece

Riffle Sample Divider Specification

- Frequency

- 50-60 Hertz (HZ)

- Usage

- Aggregate Testing Equipment

- Automation Grade

- Semi Automatic

- Operate Method

- Electric

- Material

- Stainless Steel

- Color

- Blue

- Features

- Accurate results, Robust construction, Efficient working

- Product Type

- Riffle Sample Divider

- Application

- Used for sampling aggregates, ores, refractorymaterials, pigments, powdered coal etc.

- Dimension (L*W*H)

- 450 X 325 X 650(L X W X D) mm Millimeter (mm)

Riffle Sample Divider Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 200 Pieces Per Month

- Delivery Time

- 4 Week

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Box / Corrugated Box

- Certifications

- ISO 9001 : 2015

About Riffle Sample Divider

Used for rapid collection of the true representative sample from aggregate, sand and fillers. Consist of a metal box fitted with a series of chutes of equal width which discharge the material alternatively in opposite directions into separate pans. The chutes of the riffle are steep enough to allow rapid flowing of the material. Each riffle sample divider supplied with two pans and one scoop.

Application and Construction Details:

- Used for sampling aggregates, ores, refractorymaterials, pigments, powdered coal etc.

- It consists of PCRC sheet box mounted on legs, fitted with a series of chutes of equalwidth, which discharge the material.

- The chutes chutes of the riffle are sleep enough to allow rapid flowing of the material.

- Each riffle sample divider supplied with two pans and one scoop.

- Divider Size: 20mm

- No of slots: 16 Nos

- MOC: G.I.

Also available in 20 MM , Number of Slot : 16, 40 MM, Number of Slot : 12, 50 MM, Number of Slot : 8, 75 MM, Number of Slot : 6, 12.5 MM, Number of Slot : 16, 25 MM, Number of Slot :16

Further details availableon our website.

The Price mentioned here are subject to change as per the capacity,specifications and application of the user.

Accurate and Consistent Sampling

Designed for laboratories and industrial settings, the Riffle Sample Divider divides bulk materials into equal, representative portions for analytical testing. With robust construction and exact dimensions (450 x 325 x 650 mm), it minimizes sample variance, making it an indispensable tool for quality assurance.

Versatility Across Materials

This divider is suitable for an array of materials including aggregates, ores, refractory compounds, pigments, and powdered coal. Its adaptable design serves the needs of varied industries, offering precision and dependability in every split.

FAQs of RIFFLE SAMPLE DIVIDER:

Q: How does the Riffle Sample Divider work for aggregate testing?

A: The Riffle Sample Divider operates by passing bulk materials through a series of alternating chutes, splitting the sample into equal and representative portions. This mechanical process ensures consistent and unbiased subdivision for reliable aggregate testing.Q: What types of materials can be sampled using this divider?

A: This sample divider is engineered for diverse materials, including aggregates, ores, refractory materials, pigments, and powdered coal. Its robust design accommodates both fine and coarse materials commonly used in laboratory and industrial applications.Q: When should you use a sample divider in aggregate testing?

A: You should use a sample divider whenever you need to obtain accurate, representative samples from bulk materials before laboratory testing. This is essential for quality control and compliance with industry standards.Q: Where is the Riffle Sample Divider commonly used?

A: The divider is predominantly used in laboratories, quality control departments, research facilities, and material testing units of manufacturers, exporters, service providers, suppliers, and traders across India.Q: What is the process for dividing samples using this equipment?

A: Simply pour the bulk material evenly across the top. The material flows through the alternating chutes, splitting into two equal portions. You can repeat the process as needed to reduce sample size while ensuring consistency.Q: What benefits does this equipment offer to users?

A: The divider guarantees representative sampling, reduces human error, and speeds up the sample preparation process. This results in more accurate laboratory analyses and enhanced confidence in material quality assessments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

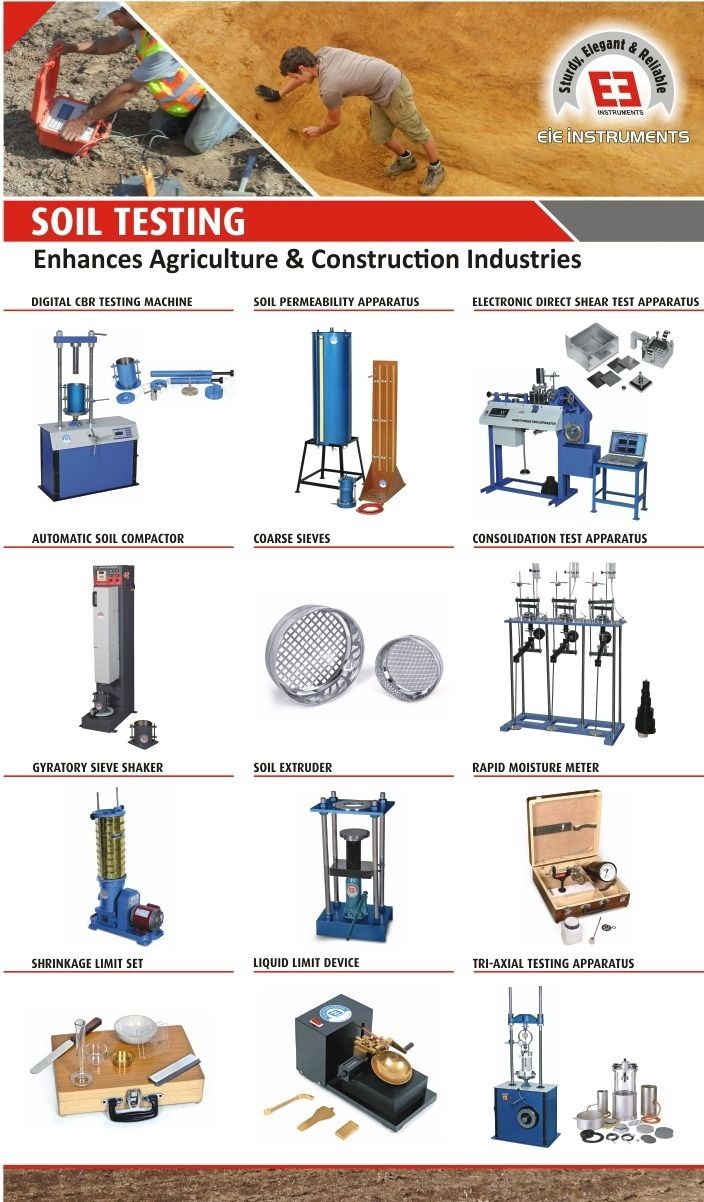

More Products in Aggregate Testing Equipments Category

Aggregate Testing Equipment

Price 1.00 INR / Piece

Minimum Order Quantity : 1

Product Type : Aggregate Testing Equipment

Features : Corrosionresistant, robust design, userfriendly

Automation Grade : Automatic

Usage : Industrial testing laboratory

ACCELERATED AGGREGATE (ROADSTONE) POLISHING MACHINE

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : ACCELERATED AGGREGATE (ROADSTONE) POLISHING MACHINE

Features : Heavy duty, low maintenance, corrosion resistant

Automation Grade : SemiAutomatic

Usage : AGGREGATE TESTING EQUIPMENTS

Jaw Crusher

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : Jaw crusher

Features : Heavy duty construction, adjustable output size, high crushing efficiency

Automation Grade : SemiAutomatic

Usage : Industrial

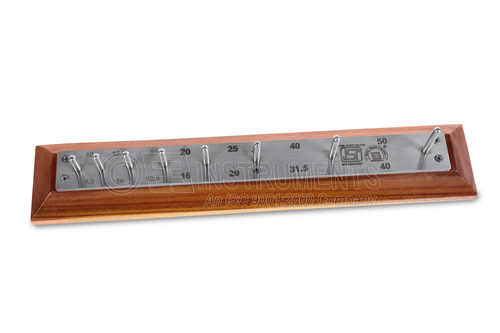

ISI Marked - Length Gauge

Price 3000 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : ISI Marked Length Gauge

Features : Six hardened steel pins for aggregate measurement, ISI Marked, corrosion resistant

Automation Grade : Manual

Usage : Aggregate Testing Equipment

|

EIE INSTRUMENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry