Marshal Stability Testing Machine (With Proving Ring and Dial Gauge)

Marshal Stability Testing Machine (With Proving Ring and Dial Gauge) Specification

- Product Type

- MARSHAL STABILITY TESTING MACHINE-(4" DIA)-(WITH PROVING RING AND DIAL GAUGE)

- Frequency

- 50-60 Hertz (HZ)

- Color

- Silver

- Automation Grade

- Semi Automatic

- Material

- Stainless Steel

- Usage

- used to measure the resistance to plastic flow of cylindrical specimens of bituminous mixture loaded on the lateral surface.

- Features

- Accurate results, Robust construction, Efficient working

- Application

- Bitumen Testing Equipment

- Operate Method

- Electric

Marshal Stability Testing Machine (With Proving Ring and Dial Gauge) Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- Ahmedabad

- Supply Ability

- 100 Pieces Per Month

- Delivery Time

- 4 Week

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Box / Corrugated Box

- Main Domestic Market

- All India

- Certifications

- ISO 9001 : 2015

About Marshal Stability Testing Machine (With Proving Ring and Dial Gauge)

Compliance With Following National / International Standards:

ASTM D6927, ASTM D1559Available in : 4" Dia Specimen Size and 6" Dia Specimen Size or COMBINED

It is used to measure the resistance to plastic flow of cylindrical specimens of bituminous mixture loaded on the lateral surface.

Further details available on our website.

Price and specifications mentioned here are subject to change as per the application, customer requirements and prevailing market conditions. Please refer to us for the final rates and offer.

Efficient Testing for Bituminous Materials

Marshal Stability Testing Machine offers a streamlined and dependable method for measuring plastic flow resistance in bituminous mixtures. The automatic system paired with a proving ring and dial gauge ensures that every test adheres to industry standards, making it an indispensable tool for those involved in bitumen testing across India.

Robust Construction and Reliable Operation

Constructed from high-grade steel, the machine is engineered for long-term performance and durability. Its blue and silver design adds a modern touch, while the 230 Volt operation guarantees consistent results during frequent laboratory use. The accompanying 1-year warranty backs its reliability.

FAQs of Marshal Stability Testing Machine (With Proving Ring and Dial Gauge):

Q: How does the Marshal Stability Testing Machine determine resistance to plastic flow?

A: The machine evaluates the resistance to plastic flow by applying a lateral load on cylindrical bituminous specimens. Using the proving ring and dial gauge, it accurately measures the force required to deform the sample, providing reliable data for bitumen quality assessment.Q: What are the main benefits of using this automatic testing equipment?

A: The automatic operation minimizes manual intervention, resulting in faster, repeatable, and precise test results. Users benefit from increased laboratory efficiency and dependable testing outcomes, ensuring quality control in bituminous material production.Q: When should the Marshal Stability Testing Machine be used?

A: This machine is ideal for use during routine quality control, research and development, and when assessing compliance with bitumen standards. It ensures timely testing during the manufacturing or construction process, aiding in the monitoring of material properties.Q: Where is the machine most commonly utilized?

A: It is widely employed in bitumen and asphalt testing laboratories, research institutions, and quality assurance centers throughout the construction and road-building sectors in India.Q: What is the process for testing bitumen mixtures with this machine?

A: First, a cylindrical bituminous specimen is prepared and positioned in the testing chamber. The machine then applies a lateral load to the sample, and the proving ring with dial gauge records the required force, revealing the materials resistance to plastic flow.Q: How can users ensure correct usage and maintenance of the equipment?

A: Users should follow the provided operational guidelines, ensure accurate specimen preparation, and perform regular calibration checks. Periodic cleaning and professional servicing, as detailed in the warranty, guarantee optimal performance and longevity.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Civil Testing Instruments Category

TRIAXIAL TESTING MACHINE FOR ROCK

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Application : Rock Triaxial Compression Testing

Usage : Rock Testing Equipment

Specimen Size : 38 mm, 50 mm diameter x 100 mm length

Power Supply : 220V AC, 50Hz

DIRECT SHEAR APPARATUS HAND OPERATED

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Application : The equipment is used for Direct Shear Laboratory Test of Rock Samples. The test measures peak & residual Direct Shear Strength as a function of stress normal to the sheared plane. The equipment can be used for testing Core, Lump specimens.

Usage : Rock Testing Equipment

Specimen Size : Typically up to 60 mm x 60 mm x 25 mm (shear box size)

Power Supply : Not Required (Manual Operation)

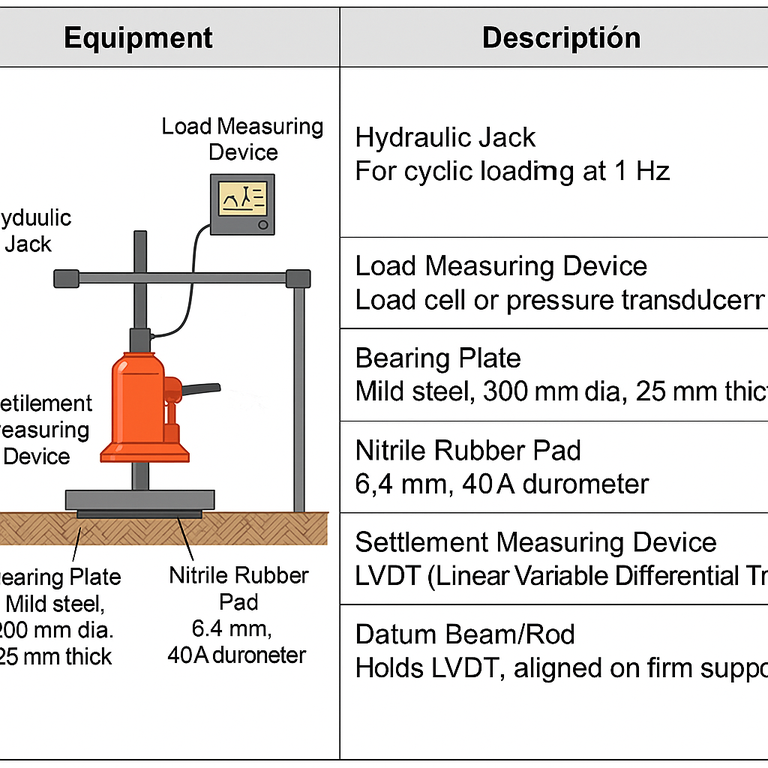

CYCLIC PLATE LOAD TEST

Minimum Order Quantity : 1 Piece

Application : GEOTEXTILE & GEOMEMBRANE TESTING INSTRUMENTS

Usage : GEOTEXTILE & GEOMEMBRANE TESTING INSTRUMENTS

Specimen Size : 300 mm dia. or as per requirement

Power Supply : 220V/50Hz AC

ASPHALT MIXER-THEORETICAL DENSITY METER-WITH VACUUM PUMP

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Application : Measurement of theoretical maximum specific gravity of asphalt mixtures

Usage : Civil Engineering, Road Construction Quality Control

Specimen Size : Typically 10004000 g asphalt mix

Power Supply : 230V AC, 50 Hz

|

EIE INSTRUMENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry