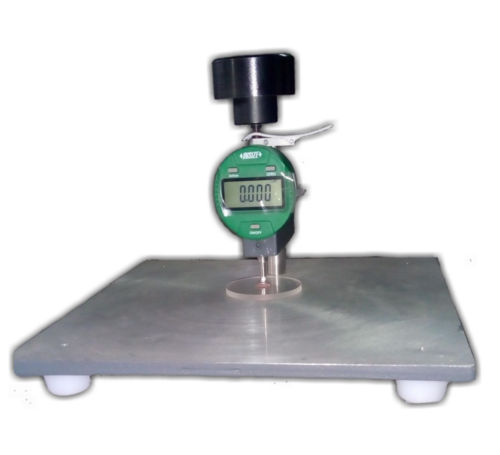

Dead Weight Type Digital Thickness Gauge - 2 KPA - 0.001 X 10 mm

Dead Weight Type Digital Thickness Gauge - 2 KPA - 0.001 X 10 mm Specification

- Usage

- Civil Engineering Testing Equipment

- Frequency

- 50-60 Hertz (HZ)

- Color

- Grey

- Operate Method

- Electric

- Application

- Suitable to measure Thickness of Geotextile, Geocomposite, Geonets, HDPE Geomembrane & Geomembrane material

- Features

- Accurate results, Robust construction, Efficient working

- Product Type

- Digital Thickness Gauge - Dead Weight Type

- Material

- Stainless Steel

- Automation Grade

- Semi Automatic

Dead Weight Type Digital Thickness Gauge - 2 KPA - 0.001 X 10 mm Trade Information

- Minimum Order Quantity

- 1 Number

- Supply Ability

- 100 Per Month

- Delivery Time

- 4 Week

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Box / Corrugated Box

- Certifications

- ISO 9001 : 2015

About Dead Weight Type Digital Thickness Gauge - 2 KPA - 0.001 X 10 mm

Applications:

Suitable to measure Thickness of Geotextile, Geocomposite, Geonets, HDPE Geomembrane & Geomembrane material

Salient Features:

- Dead-weight type

- Anvil Type: Flat

- Range: 0 to 10 mm

- Resolution: 0.001 mm (1 micron)

- Dial Type: Digital

- Mounting: Self Standing table top

- Power: Button cell for digital sensor

- Digital gauge make: INSIZE

- Lifting Lever: Manual Lifting Lever(Press to open, release to measure)

-

- This equipment generally confirms to TAPPI OR ASTM OR ISO standards

Furtherdetails available on our website.

The Price mentioned here are subject to change as per the capacity,specifications and application of the user.

High-Precision Thickness Measurement

This digital thickness gauge employs dead weight technology to provide accurate and repeatable thickness readings for geosynthetic materials. The 2 KPA pressure ensures measurements under standardized conditions, making it ideal for testing materials used in civil engineering, including geotextile fabrics and HDPE geomembranes.

Engineered for Civil Engineering Testing

Designed to meet the needs of the civil engineering sector, the gauge is particularly suitable for quality control and materials testing in construction and infrastructure projects. Its robust build and digital interface make it user-friendly and reliable for professionals requiring high accuracy.

FAQs of Dead Weight Type Digital Thickness Gauge - 2 KPA - 0.001 X 10 mm:

Q: How does the Dead Weight Type Digital Thickness Gauge ensure accurate measurements?

A: The gauge uses a dead weight mechanism to apply a consistent 2 KPA pressure on the sample, minimizing measurement errors due to varying force. Its digital sensor provides precise results with an accuracy of up to 0.001 mm, ensuring reliable thickness measurements across geotextile and geomembrane materials.Q: What materials can be tested with this digital thickness gauge?

A: This instrument is ideal for measuring thickness of geotextiles, geocomposites, geonets, HDPE geomembranes, and other geomembrane materials commonly used in civil engineering projects.Q: When should this thickness gauge be used in a civil engineering project?

A: The gauge should be used during material inspection phases, quality assurance routines, and when verifying material compliance before and during construction activities. It is crucial wherever precise determination of geosynthetic thickness impacts project integrity and performance.Q: Where is the Dead Weight Type Digital Thickness Gauge most beneficial?

A: This device is most beneficial in laboratories, manufacturing units, or on-site quality control labs for civil engineering, infrastructure development, and geosynthetics manufacturing, particularly where compliance with material specifications is required.Q: What is the process for measuring thickness using this instrument?

A: To measure thickness, place the sample under the gauges pressure foot, ensure the dead weight mechanism applies 2 KPA pressure, and allow the digital display to provide a direct thickness reading. Follow manufacturers guidelines for calibration and operation.Q: What are the primary benefits of using this digital thickness gauge?

A: Key benefits include high measurement precision, consistent repeatability due to the dead weight design, ease of digital readout, and suitability for a variety of geosynthetic materials. It streamlines process validation and quality assurance for professionals in the civil engineering field.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Civil Testing Instruments Category

TRIAXIAL TESTING MACHINE FOR ROCK

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Features : Sturdy frame, Userfriendly controls, Precision loading

Frequency : 50/60 Hz

Application : Rock Triaxial Compression Testing

Usage : Rock Testing Equipment

Solar Cell Testing Equipment

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Features : High Precision Measurement, RealTime Monitoring, Data Storage

Frequency : 50 Hz

Application : Solar Module, Solar Cell Performance Analysis

Usage : Solar Testing Equipment

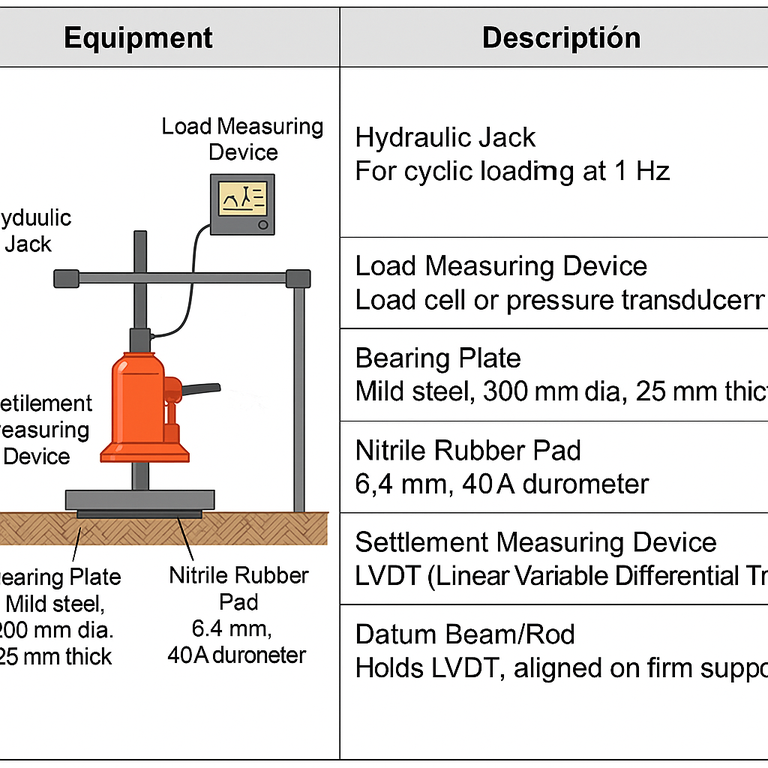

CYCLIC PLATE LOAD TEST

Minimum Order Quantity : 1 Piece

Features : Sturdy Construction, Precise Measurement, Portable

Frequency : 50 Hz

Application : GEOTEXTILE & GEOMEMBRANE TESTING INSTRUMENTS

Usage : GEOTEXTILE & GEOMEMBRANE TESTING INSTRUMENTS

Load Truss

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Features : Sturdy frame, modular design, overload protection

Frequency : 50 Hz

Application : Load bearing, structure testing, and material strength

Usage : Industrial Load Testing

|

EIE INSTRUMENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry