Thermal Conductivity Test Apparatus

Price 1.00 INR/ Piece

Thermal Conductivity Test Apparatus Specification

- Power Supply

- 230V AC, 50 Hz

- Automation Grade

- Semi-automatic

- Application

- Designed to determine Thermal Conductivities of insulating materials in the form of slabs

- Product Type

- Cement Testing Equipment

- Features

- Microprocessor based control, Overheat protection, Compact design

- Color

- White

- Test Range

- 0.02 to 1.0 W/mK

- Operating Voltage

- 230V AC

- Mounting Type

- Table Top

- Usage

- For Cement Testing Equipment

- Port Size

- Standard inch

- Accuracy

- 1% of reading

- Display Type

- Digital

- Response Time

- Less than 90 seconds

- Resolution

- 0.001 W/mK

- Equipment Type

- Thermal Conductivity Test Apparatus

- Interface Type

- LCD Digital Display

- Specimen Size

- 300 mm x 300 mm x 25-100 mm

- Measuring Range

- 0.02 to 1.0 W/mK

- Gas Pressure

- 0.2 to 2 kg/cm

- Number of Specimens

- 1

- Max Height

- 300 mm (Specimen Height)

- Humidity

- 40% to 95% RH (controlled)

- Temperature

- Ambient to 100C

- Frequency

- 50 Hz

- Capacity

- Single sample

- Machine Weight

- Approx. 75 kg

- Test Speed

- Adjustable as per test requirement

- Test Width

- Up to 300 mm

- Test Stroke

- 50 mm to 300 mm (adjustable)

- Control Mode

- Digital Temperature Controller

- Calibration

- Factory calibrated, user djustable

- Color

- White

- Heat Source

- Electric Heating Plate

- Product Type

- Cement Testing Equipment

- Sensor Type

- Thermocouple (K-type)

- Safety Features

- Thermal circuit break, earthing protection

- Cooling System

- Natural & optional forced air

- Thermal Insulation Material

- Asbestos or ceramic wool lining

- Compliance

- IS 3346 / ASTM C177

- Panel Material

- CRC Sheet with powder coating

- Dimension (L*W*H)

- 500 mm x 350 mm x 450 mm (approx.)

- Heat Flow Measurement

- Guarded Hot Plate Method

Thermal Conductivity Test Apparatus Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- Ahmedabad

- Supply Ability

- 100 Pieces Per Month

- Delivery Time

- 8 Week

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Box / Corrugated Box

- Main Domestic Market

- All India

- Certifications

- ISO 9001 : 2015

About Thermal Conductivity Test Apparatus

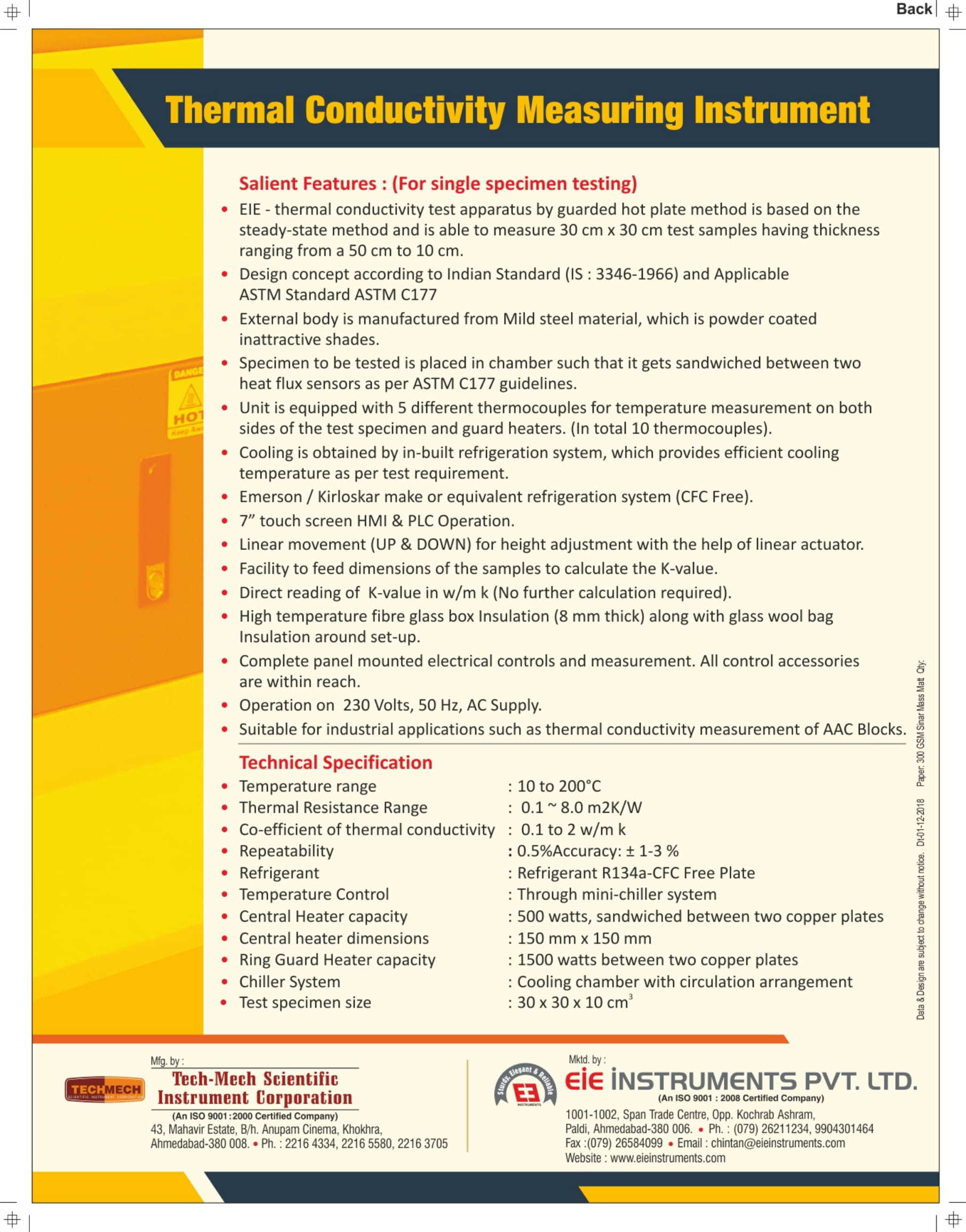

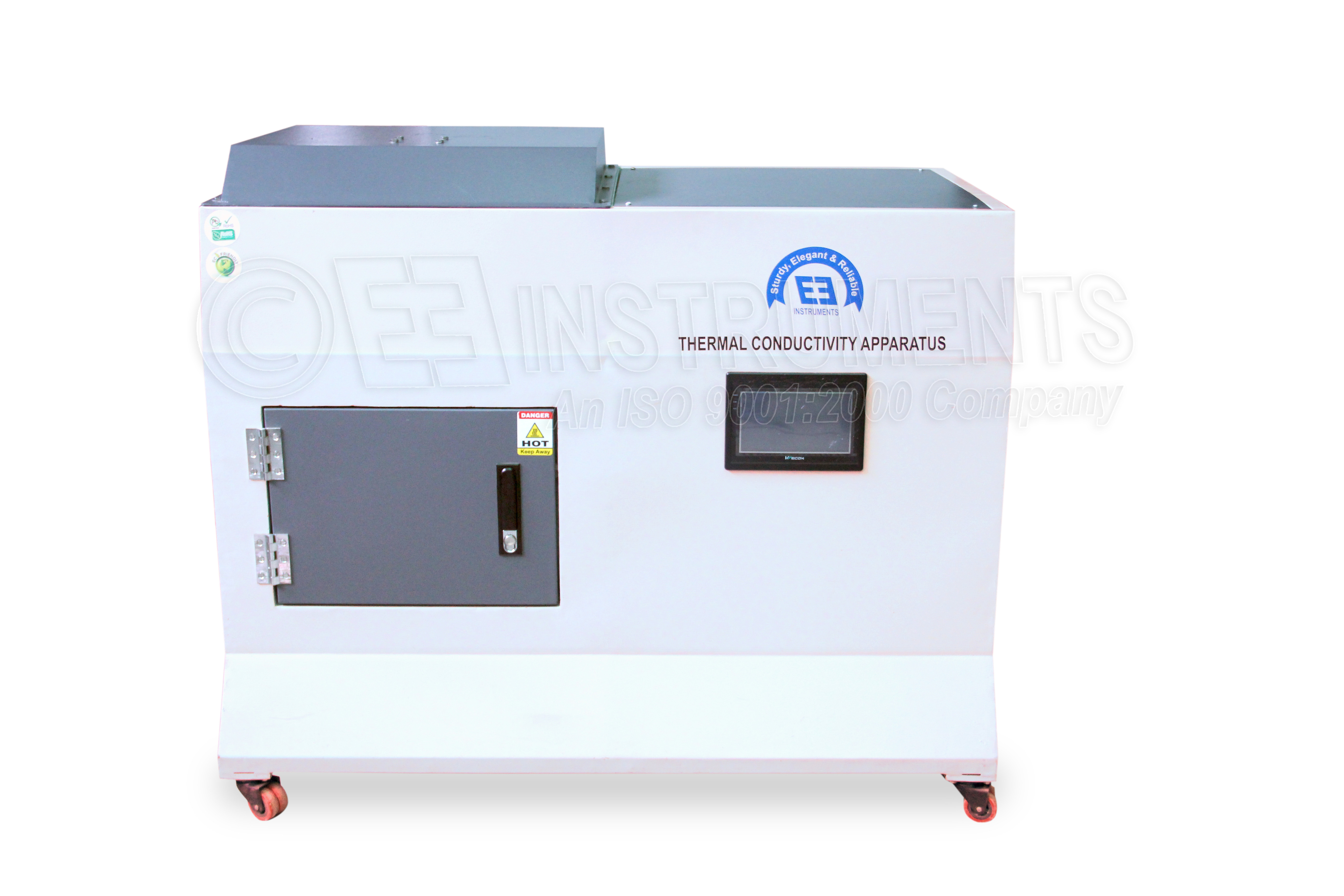

EIE Thermal Conductivity Apparatus is designed to determine Thermal Conductivities of insulating materials in the form of slabs. The Apparatus consists of main central heater sandwiched between the test specimens. Cooling plates are provided on the either side of the specimen. Single identical specimen are Clamped between heaters and cooling plate. Ring guard heater ensures Undirectional heat flow through specimen.

Further details available on our website.

The Price mentioned here are subject to change as per the capacity,specifications and application of the user.

Reliable Cement Testing with Precision

This apparatus is crafted for laboratories and industries dedicated to evaluating the thermal properties of insulation materials, particularly those used in cement and construction. Featuring advanced digital controls, users can easily adjust temperature and test speed for optimal results. The unit meets IS 3346 and ASTM C177 standards, ensuring compliance across global and domestic projects.

User-Friendly and Safe Design

Operator safety is prioritized with built-in overheat protection, thermal circuit breakers, and proper earthing. The user interface, managed via a digital LCD and microprocessor-based system, offers real-time monitoring and swift setup. The table-top, compact configuration is suitable for limited laboratory space, and the powder-coated CRC panel ensures resilience against corrosion.

FAQs of Thermal Conductivity Test Apparatus:

Q: How does the Thermal Conductivity Test Apparatus determine the conductivity of insulation materials?

A: The apparatus uses the Guarded Hot Plate method, where a calibrated electric heating plate heats one side of the insulating specimen while thermocouples measure the temperature gradient across it. The heat flow is regulated and measured accurately, enabling calculation of the samples thermal conductivity.Q: What types of samples can be tested with this device?

A: It is specifically designed to test insulating slabs, particularly those used in cement construction, with specimen dimensions ranging from 300 mm x 300 mm and thicknesses between 25 mm to 100 mm. Only one sample is tested at a time for maximum accuracy.Q: When should calibration of the apparatus be performed?

A: The apparatus comes factory-calibrated, but users can adjust calibration as needed, especially after prolonged use or when switching to significantly different specimen materials, to ensure ongoing accuracy.Q: Where is this instrument typically used?

A: This product is ideal for laboratory environments in cement and construction material testing facilities, quality control departments, research institutions, and manufacturing units engaged in insulation evaluation and product development.Q: What is the process of conducting a thermal conductivity test with this equipment?

A: First, place a properly sized specimen in the test chamber. Set required parameters via the digital controller, and start the test. The apparatus automatically regulates heat flow and monitors the temperature difference, displaying thermal conductivity on the digital LCD once the test completes.Q: How does the apparatus ensure accurate and safe operation?

A: Accuracy is maintained through a microprocessor-based digital control, K-type thermocouples, and guarded heat flow measurement. Safety is reinforced by overheat protection, a thermal circuit breaker, and firm earthing, preventing equipment damage and ensuring user safety.Q: What are the main benefits of using this apparatus for cement testing?

A: Key advantages include high measurement accuracy (1% of reading), fast response times, digital control for ease of use, durable build quality, compliance with international standards, and enhanced operational safety, making it suitable for routine and advanced material testing.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Concrete Testing Equipment Category

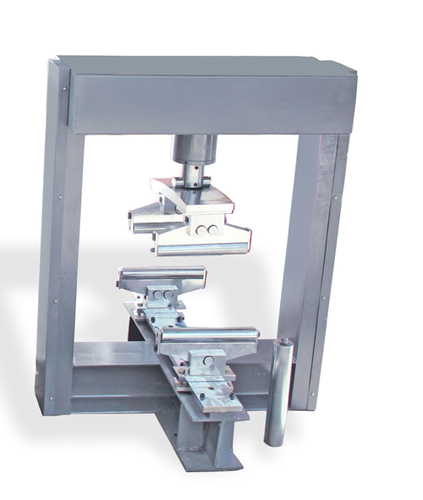

Flexural Attachment For Semi Automatic

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Automation Grade : SemiAutomatic

Features : Corrosionresistant finish, robust build, precise measurement

Usage : Industrial laboratory use

Machine Weight : Approx. 18 kg

Accelerated Curing Tank- With Heating And Cooling

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Automation Grade : Automatic

Features : Stainless steel tank, automatic temperature control, rapid heating/cooling

Usage : Laboratory concrete curing

Machine Weight : 130 kg approx.

Accelerated Carbonation Chamber

Price 700000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Automation Grade : Semi Automatic

Features : Accurate results, Robust construction, Efficient working

Usage : Concrete Testing Equipment

Machine Weight : 176 Kilograms (kg)

Cube Mould

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Automation Grade : Manual

Features : Rigid construction, corrosion resistant, ISI marked

Usage : For Concrete Testing

Machine Weight : Approx. 4 kg to 10 kg

|

EIE INSTRUMENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry