Thermal Calibration and Validation Services

Price 1.00 INR/ Piece

Thermal Calibration and Validation Services Specification

- Resolution

- 0.01C

- Frequency

- 50Hz

- Mounting Type

- Portable setup or wall-mountable

- Operating Voltage

- 230V AC

- Power Supply

- 230V AC, 50Hz

- Equipment Type

- Service (Thermal Calibration & Validation)

- Temperature

- -40C to 150C

- Automation Grade

- Automatic / Manual

- Response Time

- Instantaneous logging

- Test Range

- User-defined (based on probe/chamber)

- Interface Type

- USB, RS-232, wired, wireless

- Port Size

- Standard calibration port sizes

- Display Type

- Digital, external PC

- Application

- Hospital, Laboratory, Pharma, Industrial, Food

- Max Height

- Custom for chamber

- Features

- IQ/OQ/PQ documentation, traceability, multi-channel, real-time monitoring, graph plotting

- Measuring Range

- -40C to 150C

- Number of Specimens

- Up to 8 simultaneous channels

- Specimen Size

- Thermocouple/RTD sensors as required

- Accuracy

- 0.1C (standard); up to 0.01C (reference)

- Humidity

- 10% to 90% RH

- Usage

- Freezer, incubator, oven, autoclave, warehouse validation

- Capacity

- Multi-point reference calibration

- Machine Weight

- Custom as per service equipment

- Test Speed

- Variable, programmed per instrument

- Test Width

- Applicable to calibration chamber size

- Control Mode

- Fully automated / manual

- Real Time Monitoring

- Yes

- Calibration Cycle

- Annual, quarterly, or custom

- Software Features

- Audit trail, graphing, parameter export

- Support

- On-site and off-site calibration

- Data Logging

- Continuous, export in Excel/PDF formats

- Traceability

- International/national standards

- Reporting

- Detailed calibration and validation report, Certificate of Calibration

- Contact

- Technical team for scheduling

- Documentation

- Compliant to regulatory norms (FDA, WHO, GMP)

- Environmental Conditions

- Calibrated in working conditions

- Service Standards

- ISO 17025, NABL accredited

- Sensor Types Supported

- RTD, Thermocouple (J, K, T, E, R, S, B)

- Calibration Method

- Reference sensor comparative method

Thermal Calibration and Validation Services Trade Information

- Minimum Order Quantity

- 1 Piece

- Packaging Details

- Wooden Box

About Thermal Calibration and Validation Services

Sophisticated master calibration instruments, NABL Traceability of generated certificates, NABL Accredited calibration laboratory, Experienced calibration engineers, Professional set-up, Excellent service setup, On-site calibration service with separate calibration tools, 2 separate sets of master calibration instruments - For On site and For Laboratory, Pressure calibration services, ELECTRO-TECHNICAL calibration services, Mass Volume calibration services, Thermal calibration services, RPM Calibration services, Clean room validation services, Force calibration services, Proving ring calibration servicesUnmatched Accuracy and Compliance

Our calibration and validation services deliver reliability and peace of mind, adhering to the strict standards of ISO 17025 and NABL accreditation. All processes and reports are traceable to international or national references and comply with regulatory bodies like FDA, WHO, and GMP, supporting both quality and audit requirements.

Comprehensive Reporting & Data Management

Receive detailed calibration and validation reports, along with certificates verifying each process. Our data logging captures continuous readings, which can be exported in Excel or PDF formats. Advanced software features include audit trails, graphical analyses, and parameter exports for seamless integration into your quality management systems.

Versatile On-site & Off-site Service

Calibration can be performed either at your facility or ours, adapting to your operational needs. We calibrate environmental conditions in the working state of your equipment, serving everything from freezers to incubators and autoclaves, with cycle schedules tailored to your regulatory compliance.

FAQs of Thermal Calibration and Validation Services:

Q: How is thermal calibration and validation performed for my equipment?

A: We employ a reference sensor comparative method, utilizing traceable RTD and thermocouple sensors (J, K, T, E, R, S, B) to compare your instruments readings. Calibration is conducted under actual working conditions, ensuring accuracy within 0.1C (standard) or up to 0.01C (reference) across a measuring range of -40C to 150C.Q: What types of sensors and equipment can you calibrate?

A: We support a wide range of sensor types, including RTD and thermocouple sensors, compatible with various equipment such as freezers, ovens, autoclaves, incubators, and warehouse environments. Both portable and wall-mountable setups are available for flexible deployment.Q: When should I schedule calibration or validation for my instruments?

A: Calibration cycles are offered as annual, quarterly, or custom intervals, ensuring compliance with regulatory standards and your operational requirements. Regular calibration is recommended to maintain measurement accuracy and satisfy audit norms.Q: Where is the calibration service carried out?

A: You can opt for on-site calibration at your location for minimal workflow disruption or off-site at our NABL-accredited facility. Calibrations are performed under actual equipment operation conditions to guarantee relevancy and precision.Q: What is the reporting and documentation process?

A: Our service includes comprehensive calibration and validation reports, IQ/OQ/PQ documentation, and certificates detailing traceability to international/national standards. All data logs are exportable in Excel and PDF formats, and records comply fully with audit and regulatory norms.Q: How can I benefit from regular thermal calibration and validation?

A: Routine calibration ensures precision, enhances equipment reliability, and facilitates compliance with FDA, WHO, and GMP standards. It helps detect drift or faults early, safeguarding product quality and supporting smooth regulatory audits.Q: What support is available if I encounter issues during calibration?

A: Our technical team provides full support, offering both on-site and remote assistance. We help you through scheduling, troubleshooting, and ensuring your calibration needs are promptly addressed.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Soil Testing Equipments Category

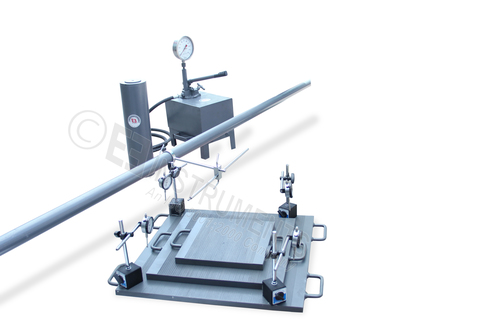

Plate Bearing Test Apparatus

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Control Mode : Manual/Hydraulic

Temperature : 5C to 45C

Resolution : 0.01 mm

Mounting Type : Ground Mount

Compact Cbr Load Frame Three Speed E.O.

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Control Mode : Electric Operation (E.O.)

Temperature : 5C to 40C

Resolution : 0.01 kN

Mounting Type : Benchtop

Automatic Soil Compactor

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Control Mode : Automatic

Temperature : 10C to 40C operating range

Resolution : 1 blow

Mounting Type : Floor Mounted

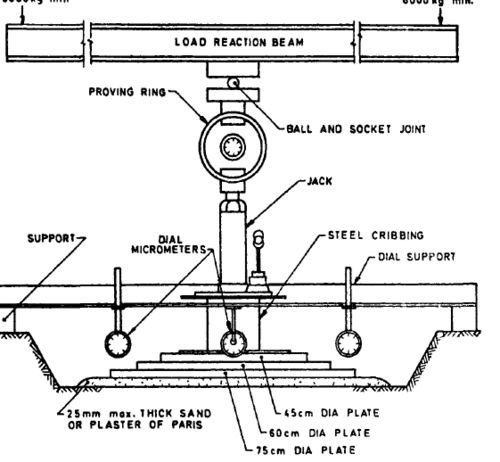

DETERMINATION OF MODULUS OF SUBGRADE REACTION (K-VALUE) OF SOILS IN FIELD

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Control Mode : Manual & Hydraulic

Temperature : 0C to 50C

Resolution : 0.01 mm

Mounting Type : On field surface

|

EIE INSTRUMENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry