Tensile Testing Machine for HDPE Bag

Price 1.00 INR/ Piece

Tensile Testing Machine for HDPE Bag Specification

- Voltage

- 230 Volt (v)

- Display Type

- Digital

- Features

- Accurate results, Robust construction, Efficient working

- Product Type

- Tensile Testing Machine

- Usage

- Industrial

- Material

- Stainless Steel

- Color

- White & Black

- Frequency

- 50-60 Hertz (HZ)

- Capacity

- 0-250 Kgf (0-2500 N) Kg

Tensile Testing Machine for HDPE Bag Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 100 Pieces Per Month

- Delivery Time

- 4 Week

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Box / Corrugated Box

- Main Domestic Market

- All India

- Certifications

- ISO 9001 : 2015

About Tensile Testing Machine for HDPE Bag

Applications:

For CEMENT HDPE BAG Tensile Strength Test

Overview:

Computerized Tensile Strength testing machine having capacity of 0 to 250 Kgf. Supplied complete with dedicated software program. Equipped with ball screw, Induction Motor and drive along with encoder to measure the elongation using pair of grips. Grip is available at extra cost and quoted separately.

Salient Features:

- Floor standing model

- Aesthetic outer appearance

- Unique and compact design features

- Fitted with Microprocessor based PROGRAMMABLE Logical controller

- Computer interface through USB Drive

- Equipped with Ball screw for friction less traverse

- Rotary encoder for high accuracy in elongation

- Reputed make induction motor with dedicated gear box and drive for speed variation and to maintain speed at high torque

- Easy to use display unit (controller part) and software

- Inbuilt Over Load Safety

- Inbuilt Over Travel Safety

- Auto Reverse facility

- Auto Break

- You can get graph for load v/s elongation and also get a excel sheet with a single click

Furtherdetails available on our website.

The Price mentioned here are subject to change as per the capacity,specifications and application of the user.

Compliance with Global Standards

This Tensile Testing Machine adheres to stringent international standards such as IS, ASTM, EN, ASHTHO, and ISO. As a result, it ensures your cement HDPE bags meet industry requirements, supporting quality control and certification processes for both local and international markets.

Robust Industrial Application

Built for industrial use, this machine effectively tests the tensile strength of HDPE bags meant for cement packaging. Its design and functionality cater to the needs of exporters, manufacturers, and service providers seeking precise and repeatable results.

User-Friendly Features

The equipment comes in white and black color options and operates on a standard 230 Volt supply, making it adaptable for most industrial settings. Its interface supports effortless operation, promoting efficiency and reliability during tensile strength assessments.

FAQs of Tensile Testing Machine for HDPE Bag:

Q: How does the Tensile Testing Machine test the strength of HDPE cement bags?

A: The machine applies controlled tensile force to the HDPE bag sample until it breaks, measuring the maximum force required. This process evaluates the tensile strength, ensuring that the bags meet safety and durability criteria according to various standards.Q: What standards does this machine comply with for tensile testing?

A: The machine adheres to multiple international and national standards, including IS, ASTM, EN, ASHTHO, and ISO, ensuring consistency and reliability in test results for cement HDPE bags.Q: When should tensile strength testing be performed on HDPE cement bags?

A: Tensile strength testing should be conducted during quality assurance procedures, before product shipment, or when introducing new materials or suppliers to verify that packaging meets durability requirements.Q: Where can this Tensile Testing Machine be installed and used?

A: This machine is suitable for installation in industrial settings such as quality control laboratories, manufacturing units, and testing facilities in organizations involved in cement packaging.Q: What is the process for operating the Tensile Testing Machine?

A: First, a sample HDPE bag strip is clamped into the machine. The test is initiated, and the machine gradually pulls the sample until it breaks while measuring the tensile force. Data is then recorded for assessment against standard thresholds.Q: How is the machine beneficial for manufacturers and exporters?

A: By guaranteeing packaging strength and compliance with international standards, the machine helps manufacturers and exporters avoid product failures, maintains reputation, and opens up export opportunities by fulfilling global market criteria.Q: What warranty and support are available for this machine?

A: This Tensile Testing Machine includes a 1-year warranty, providing peace of mind and service support to ensure reliable operation and minimal downtime in industrial environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Cement Testing Equipment Category

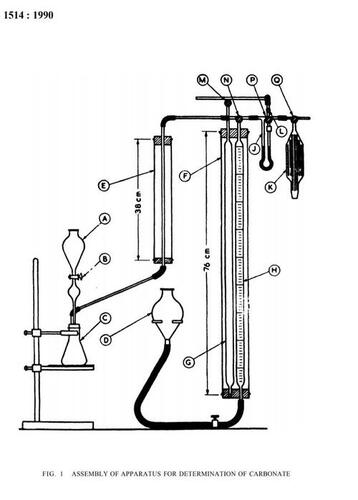

ASSEMBLY OF APPARATUS FOR DETERMINATION OF CARBONATE

Price 1.00 INR / Piece

Minimum Order Quantity : 1 , , Piece

Usage : Determination of Carbonate content in Lime and Cement

Application : ASSEMBLY OF APPARATUS FOR DETERMINATION OF CARBONATE IN LIME

Product Type : Cement Testing

Features : Leakproof Joints, Easy Assembly, Resistant to Acids

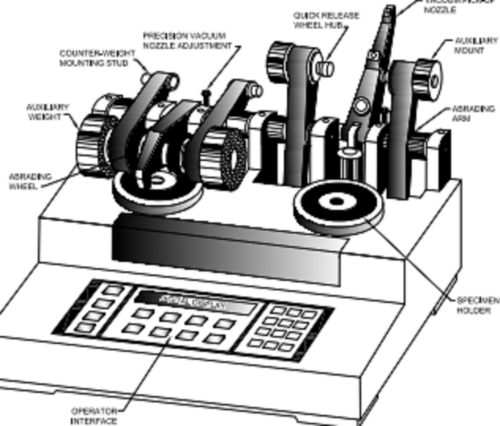

DETERMINATION OF RESISTANCE TO ABRASION

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : laboratory

Application : Industrial

Product Type : DETERMINATION OF RESISTANCE TO ABRASION AS PER IS 171902020

Features : Corrosion resistant

Accelerated Curing Tank

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Industrial

Application : Curing of Concrete Test Specimens

Product Type : Accelerated Curing Tank

Features : Double Walled Construction, Water Circulation, Digital Temperature Control

FLOW TABLE Hand Operated

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Cement Testing Equipment

Application : Determining flow of cement paste/mortar

Product Type : Flow Table for Cement Hand Operated

Features : Cast iron table with engraved lines, hand lever mechanism, conforming to standards

|

EIE INSTRUMENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry