JOMNEY END QUENCH APPARATUS WITH FURNACE

Price 1.00 INR/ Piece

JOMNEY END QUENCH APPARATUS WITH FURNACE Specification

- Display Type

- Digital/Analog (for temperature)

- Response Time

- Quick Response (within 30 secs for quenching)

- Max Height

- Approx. 600 mm

- Frequency

- 50 Hz

- Product Type

- JOMNEY END QUENCH APPARATUS - WITH FURNACE

- Port Size

- Standard Water Jet Nozzle

- Humidity

- Room Environment

- Power Supply

- 230 V AC, 50 Hz

- Usage

- Metallurgical Lab Equipment

- Number of Specimens

- 1 per test

- Measuring Range

- 1 mm to 100 mm (distance from quenched end)

- Interface Type

- Manual Controls

- Features

- Fast heating furnace, Digital temperature controller, Water quenching device

- Test Range

- Depth of Hardness (50 mm to 100 mm specimen length)

- Automation Grade

- Semi-Automatic

- Equipment Type

- JOMNEY END QUENCH APPARATUS - WITH FURNACE

- Accuracy

- 2C (temperature control)

- Hardness

- Measured via additional hardness tester

- Specimen Size

- 25 mm dia x 100 mm length (Standard)

- Operating Voltage

- 230 V AC

- Application

- The equipment consist of :Fast heating special Furnace with precisiontemperature control.

- Mounting Type

- Bench-top

- Temperature

- Ambient to 900C

- Resolution

- 1 mm (specimen measurement)

- Capacity

- Single Specimen

- Machine Weight

- Approx. 45 Kg

- Control Mode

- Manual/Automatic

- Cooling Water Supply

- Continuous with adjustable flow

- Specimen Holder

- Heat-resistant alloy clamps

- Quenching System

- Motorized water jet with flow control

- Temperature Controller

- Digital (PID based)

- Furnace Type

- Electric Resistance (Muffle) Furnace

- Compliance

- IS 3848, ASTM A255

- Water Tank Capacity

- Approx. 25 Litres

- Safety Features

- Over-temperature cut-off, earthing

- Construction

- Mild Steel with powder coating

JOMNEY END QUENCH APPARATUS WITH FURNACE Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 100 Pieces Per Month

- Delivery Time

- 4 Week

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Box / Corrugated Box

- Certifications

- ISO 9001 : 2015

About JOMNEY END QUENCH APPARATUS WITH FURNACE

- The equipment consist of Fast heating special Furnace with precisiontemperature control.

- Jominey Test Fixture with in built pumping system.

THE FAST HEATING FURNACE WILL HAVE FOLLOWING

FEATURES

- Temperature is Maximum 1200 degree with a workingtemperature 1000 degree

- LiningCeramic Fiber type with low thermalmass.

- Heatingelements is A1.

Furtherdetails available on our website.

The Price mentioned here are subject to change as per the capacity,specifications and application of the user.

Precision Heating and Quenching

Equipped with a fast-heating electric resistance muffle furnace, the JOMNEY apparatus ensures rapid and uniform temperature elevation for steel specimens. The digital PID controller provides highly accurate temperature regulation, maintaining stability up to 900C. Combined with a motorized jet quenching system, this apparatus facilitates controlled and repeatable metallurgical testing, ensuring reliable results in each experiment.

Robust Construction and Safety

Manufactured from powder-coated mild steel, this apparatus offers exceptional durability for daily laboratory use. Safety is paramount, featuring over-temperature cut-off mechanisms and proper earthing to protect both user and equipment. The heat-resistant specimen holder and continuous, adjustable water cooling further safeguard testing integrity and user safety.

Universal Lab Application

This bench-top, semi-automatic apparatus meets IS 3848 and ASTM A255 standards, making it suitable for industrial labs, research institutions, and educational facilities. Its intuitive controls, digital/analog displays, and automated features streamline the process of assessing steel hardenability, providing valuable insight into material properties for a range of metallurgical applications.

FAQs of JOMNEY END QUENCH APPARATUS WITH FURNACE:

Q: How does the JOMNEY END QUENCH APPARATUS operate during a hardenability test?

A: The apparatus heats a steel specimen in its electric resistance muffle furnace to the desired temperature using a digital PID controller. After reaching the target temperature, the specimen is transferred to the quenching station, where a motorized water jet cools it rapidly and uniformly. The resulting hardness profile is then measured along the specimens length.Q: What types of specimens can be tested with this apparatus?

A: The standard specimen size for this apparatus is 25 mm in diameter and 100 mm in length. The equipment is designed for single-specimen testing in accordance with IS 3848 and ASTM A255 standards, making it ideal for metallurgical analyses of steel.Q: When should the apparatuss safety features be checked?

A: Safety features like the over-temperature cut-off and earthing should be checked before each session. Regular inspections and functional tests help maintain safe operation and protect both the equipment and operator from potential hazards.Q: Where is the JOMNEY END QUENCH APPARATUS typically used?

A: This apparatus is primarily used in metallurgical laboratories, research centers, educational institutions, and industrial quality control labs. Its construction and compliance features make it suitable for both academic training and rigorous industrial standards.Q: What is the process for adjusting cooling water flow during a test?

A: The continuous cooling water supply features an adjustable flow control valve, allowing precise regulation for optimal quenching conditions. Adjustments are made manually on the control interface before the water jet is engaged.Q: How does the apparatus benefit metallurgical investigations?

A: By enabling controlled, reproducible hardenability testing and rapid hardness profiling along steel specimens, the apparatus assists in evaluating steel grade suitability for various industrial applications. Its precision and compliance with international standards add credibility to research and quality assurance outcomes.Q: What are the main advantages of the digital PID temperature controller?

A: The digital PID temperature controller offers 2C accuracy, quick temperature response, and stable set-point maintenance up to 900C. This ensures that specimens are consistently heated to the required temperatures, reducing uncertainty in test results.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Metallurgical Lab Equipments Category

Universal Testing Machine

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Features : Overload protection, Safety Interlock, Emergency stop, Data storage

Color : Grey

Product Type : Universal Testing Machine

Frequency : 50/60 Hz

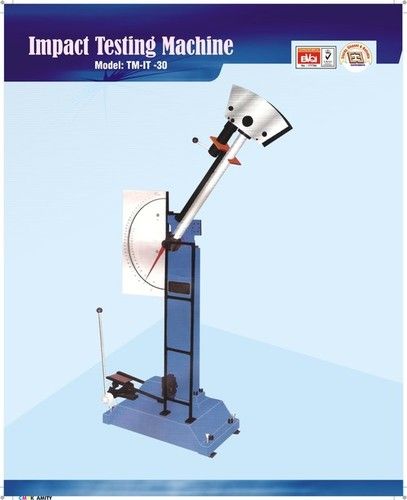

Izod Impact Testing Machine

Price 1.00 INR / Piece

Minimum Order Quantity : 1 , , Piece

Features : Robust build, Precise measurement, Easy operation

Color : Blue

Product Type : Izod Impact Testing Machine

Frequency : 50 Hz

Polariscope For Strain Viewing

Minimum Order Quantity : 1 Piece

Features : Accurate results, Robust construction, Efficient working

Color : White

Product Type : Polariscope For Strain Viewing

Frequency : 5060 Hertz (HZ)

Disc Polishing Machine

Minimum Order Quantity : 1 Piece

Features : Accurate results, Robust construction, Efficient working

Color : White

Product Type : Disc Polishing Machine

Frequency : 5060 Hertz (HZ)

|

EIE INSTRUMENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry