Disc Polishing Machine

Disc Polishing Machine Specification

- Operate Method

- Electric

- Features

- Accurate results, Robust construction, Efficient working

- Application

- Industrial

- Color

- White

- Product Type

- Disc Polishing Machine

- Automation Grade

- Semi Automatic

- Frequency

- 50-60 Hertz (HZ)

- Dimension (L*W*H)

- 71 cm. x 45 cm x 42 cm Centimeter (cm)

- Display Type

- LED display, 50 to 1000 rpm.

- Voltage

- 230 Volts, 50 Hz Volt (v)

- Material

- Stainless Steel

- Usage

- Laboratory

- Test Speed

- 300 to 900 RPM

Disc Polishing Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 100 Pieces Per Month

- Delivery Time

- 7-10 Days

About Disc Polishing Machine

In the section of metallurgical lab equipment, you can find this Disc Polishing Machine, a single disc machine with variable speed and singe AC motor. Metallography samples can be polished using this polishing machine. The polishing of the sample is carried out for the purpose of studying metal structures. The metal structures can be polished in a way that the surface becomes smooth and scratch-free. The specimen can also me mirror finished making use of the disc polishing machine.

Specifications:- Table Top design fixed Speed

- 8 Inch Disc Diameter Standard

- 1440 RPM

- Quiet Belt driven Corrosion Resistant Fibre Reinforced Plastic Cover Body with 0.5 HP AC motor operation

Superior Stainless Steel Construction

Manufactured using high-grade stainless steel, this Disc Polishing Machine guarantees robust build quality and corrosion resistance, making it ideal for rigorous laboratory and industrial use. The material choice ensures minimal maintenance and a lasting operational lifespan.

Versatile Industrial Application

Adapted for both laboratory and broader industrial settings, this machines design facilitates high-precision disc polishing, contributing to reliable sample preparation and improved analytical outcomes across various industries.

Expert Support and Export Capability

As a dedicated exporter, manufacturer, service provider, supplier, and trader in India, we provide comprehensive assistance, from installation to service and spares, ensuring that clients worldwide receive optimal product performance and support.

FAQs of Disc Polishing Machine:

Q: How does the disc polishing machine operate in a laboratory environment?

A: The machine employs a rotating disc system powered by a 230 Volt supply, enabling smooth and effective polishing of specimens. Users place the material on the disc, which then spins at controlled speeds to achieve a uniform polish, essential for laboratory sample preparation.Q: What are the benefits of using stainless steel for this machine?

A: Stainless steel offers superior resistance to corrosion and wear, ensuring that the disc polishing machine withstands harsh chemical environments commonly found in laboratories and industrial settings. This results in reduced maintenance and a longer service life.Q: When is disc polishing most beneficial in industrial applications?

A: Disc polishing is particularly valuable when preparing samples for metallographic analysis or when a high-quality finish is necessary for precise measurements. It is most beneficial before conducting microscopic examination or surface hardness tests.Q: Where can these machines be supplied or exported to?

A: As an exporter and supplier based in India, we provide our disc polishing machines to laboratories and industries both domestically and internationally, ensuring global reach through dependable logistics and support networks.Q: What is the process of polishing with this machine?

A: The process involves securing the sample on the rotating disc, often with the application of a polishing compound. The discs controlled motion smooths and refines the materials surface, resulting in a mirror-like finish suitable for analysis.Q: How does using this machine benefit laboratory workflows?

A: Using this disc polishing machine streamlines sample preparation by delivering consistent and repeatable polishing outcomes, thereby enhancing accuracy in downstream analyses and improving laboratory efficiency.Q: What kind of after-sales support can clients expect?

A: Customers receive comprehensive service, including installation guidance, operational training, maintenance assistance, and timely supply of spare parts, ensuring reliable machine performance over its lifespan.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Metallurgical Lab Equipments Category

Universal Testing Machine

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Features : Overload protection, Safety Interlock, Emergency stop, Data storage

Usage : Industrial

Product Type : Universal Testing Machine

Color : Grey

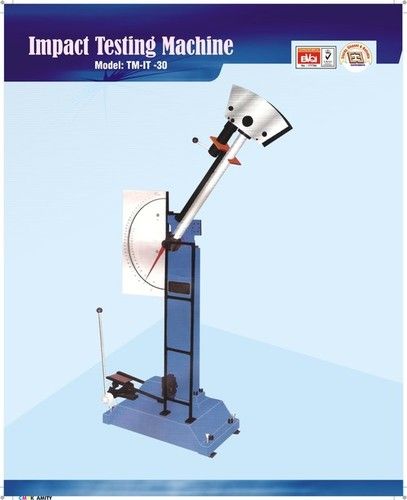

Izod Impact Testing Machine

Price 1.00 INR / Piece

Minimum Order Quantity : 1 , , Piece

Features : Robust build, Precise measurement, Easy operation

Usage : laboratory

Product Type : Izod Impact Testing Machine

Color : Blue

Polariscope For Strain Viewing

Minimum Order Quantity : 1 Piece

Features : Accurate results, Robust construction, Efficient working

Usage : Laboratory

Product Type : Polariscope For Strain Viewing

Color : White

Notch Broaching Machine

Minimum Order Quantity : 1 , , Piece

Features : Accurate results, Robust construction, Efficient working

Usage : specifically drafted for ferrous nonferrous material

Product Type : Notch Broaching Machine

Color : Gray & White

|

EIE INSTRUMENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry