Universal Testing Machine

Price 1.00 INR/ Piece

Universal Testing Machine Specification

- Product Type

- Universal Testing Machine

- Response Time

- < 0.5 sec

- Features

- Overload protection, Safety Interlock, Emergency stop, Data storage

- Port Size

- Standard

- Equipment Type

- Universal Testing Machine

- Specimen Size

- Up to 20 mm diameter

- Frequency

- 50/60 Hz

- Test Range

- 2% to 100% of machine capacity

- Operating Voltage

- 220 240 V AC

- Usage

- Industrial

- Application

- Tensile, Compression, Bending, Shear Test on Metals, Alloys, Rubber, Plastics etc.

- Max Height

- Over 1.5 m

- Automation Grade

- Semi-Automatic/Automatic

- Color

- Grey

- Resolution

- 0.01 kN

- Interface Type

- USB/RS232

- Accuracy

- 1%

- Power Supply

- 220V/50Hz, Single Phase

- Measuring Range

- 0 100 kN

- Mounting Type

- Floor mounted

- Display Type

- Digital LED/Computer Display

- Number of Specimens

- Up to 5

- Temperature

- Room Temperature to 50C

- Humidity

- 10%90% RH

- Capacity

- 100 kN (varies as per model)

- Machine Weight

- Approx. 750 kg

- Test Speed

- 0.01 500 mm/min (adjustable)

- Test Width

- 400 mm approx.

- Test Stroke

- Up to 800 mm

- Control Mode

- Computerized & Manual

- Noise Level

- < 65 dB during operation

- Safety Features

- Overload, Over travel, Limit switches

- Grip Types

- Interchangeable (for round, flat, wire, etc.)

- Load Cell Type

- Precision strain gauge type

- Maintenance

- Low and easy to service

- Data Output

- Graphical and Numeric formats

- Frame Structure

- Heavy-duty robust fabricated steel

- Software Support

- Windows Compatible Software for Data Management

- Crosshead Travel

- 800 mm (without grips)

Universal Testing Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Telegraphic Transfer (T/T), Cheque

- Supply Ability

- 100 Pieces Per Day

- Delivery Time

- 1 Week

- Main Export Market(s)

- Australia, Asia

- Main Domestic Market

- All India

About Universal Testing Machine

Available Models

200 kn, 400 kn, 600 kn, 1000 kn

Computer Controlled Universal Testing Machine

- Computerized Electronic Universal Testing Machine

- Microprocessor based control panel

- Auto ranging

- Digital display of Load and Elongation

- Dedicated PC Software

- Electronic Extensometer (At extra cost)

- Export worthy colour combinations,

- Special sheet jaws, Hard chrome plating, Hose pipes,

- Reputed make Induction/AC Servo motor

1) Tension test,

2) Compression test

3) Transverse test

Technical Specifications of Standard Accessories

| Clamping jaws for round specimens size | 10-25, 25-45, 45-70 mm (WIDTH 70) |

| Clamping jaws for flat specimens of size | 0-22, 22-44, 45-65 mm (WIDTH 70) |

| Width | 70 mm |

| Pair of compression plates | 160 mm diameter |

For Transverse test attachment

| Table with adjustable rollers | 160 mm |

| Width of rollers | 160 mm |

| Diameter of rollers | 50 mm |

| Max clearance bet supports | 800 mm |

| Radius of punch tops | 16, 22 mm |

Optional Accessories At extra cost

1) Shear test attachment for bolt

2) Wire rope test attachment

3) Rebend test attachment

4) Rebend test mandrels

Versatile Material Testing Solutions

Designed primarily for industrial environments, this Universal Testing Machine can handle a number of applications, from tensile to compression, bending, and shear tests on various materials. Its adaptable grips, exchangeable for round, flat, and wire specimens, make it an all-in-one solution for quality control and research labs. With its impressive 100 kN capacity and accurate measurement within a 1% margin, its suitable for testing metals, alloys, rubbers, or plastics.

User-Friendly Operation and Safety

This model offers flexibility with both computerized and manual control, compatible Windows software for data storage, and graphical as well as numeric data outputs. Safety is prioritized through features like overload protection, safety interlocks, and emergency stop mechanisms. The machine maintains low noise (<65 dB) and has a simple but effective maintenance design, ensuring smooth operation for every user.

Precise Performance & Efficient Data Management

Fast response time (<0.5 sec) and high resolution (0.01 kN) combine for reliable testing outcomes. Test data can be managed and exported conveniently via USB or RS232, supporting up to five specimens at a time. The stored test results can be reviewed, analyzed, and printed directly from the software, improving data-driven decision-making for industrial applications.

FAQs of Universal Testing Machine:

Q: How does the Universal Testing Machine ensure accurate test results for various materials?

A: Accuracy is achieved through a high-precision strain gauge load cell, digital LED/computer displays, and a measuring range of 0100 kN with a resolution of 0.01 kN and 1% accuracy. Adjustable test speed and interchangeable grips allow consistent testing of metals, alloys, plastics, and other materials.Q: What safety features are included for operator protection during testing?

A: The machine is equipped with overload protection, over travel safeguards, multiple limit switches, safety interlocks, and an emergency stop button to prevent accidents and ensure operator safety throughout every testing cycle.Q: When should routine maintenance be performed, and what does it typically involve?

A: Routine maintenance should be carried out periodically based on usage intensity. The design allows for easy servicing, involving regular checks of the load cell, lubrication of moving parts, calibration verification, and inspection of safety mechanisms to maintain optimal performance.Q: Where can this Universal Testing Machine be installed and who is it designed for?

A: This floor-mounted machine requires stable industrial laboratory space supporting its 750 kg weight and electrical requirements (220V/50Hz). It is ideal for manufacturers, exporters, academia, and service providers needing versatile material testing capabilities.Q: How does the software support data management and output?

A: Windows-compatible software enables efficient storage, analysis, and export of test data in both graphical and numeric formats. Interfaces like USB and RS232 facilitate easy data transfer to computers, ensuring seamless integration into laboratory information systems.Q: What are the typical usage steps for running a test on this machine?

A: The process includes mounting the specimen using the appropriate grips, configuring the test parameters (test speed, load, and type), initiating the test via manual or computer controls, monitoring real-time data on the display, and saving/exporting the test results. Safety features should always be engaged before starting tests.Q: What benefits does this Universal Testing Machine offer over standard models?

A: Its heavy-duty steel frame, wide range of test capabilities, advanced safety, easy maintenance, multi-specimen support, accurate digital readouts, and robust software compatibility set it apartpromoting reliability and efficiency in industrial and quality assurance environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Metallurgical Lab Equipments Category

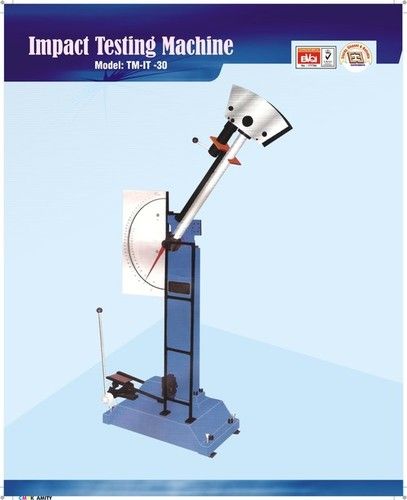

Izod Impact Testing Machine

Minimum Order Quantity : 1 , , Piece

Color : Blue

Voltage : 220240 Volt (v)

Features : Robust build, Precise measurement, Easy operation

Product Type : Izod Impact Testing Machine

Usage : laboratory

Polariscope For Strain Viewing

Minimum Order Quantity : 1 Piece

Color : White

Voltage : 220 Volt (v)

Features : Accurate results, Robust construction, Efficient working

Product Type : Polariscope For Strain Viewing

Usage : Laboratory

Disc Polishing Machine

Minimum Order Quantity : 1 Piece

Color : White

Voltage : 230 Volts, 50 Hz Volt (v)

Features : Accurate results, Robust construction, Efficient working

Product Type : Disc Polishing Machine

Usage : Laboratory

Notch Broaching Machine

Minimum Order Quantity : 1 , , Piece

Color : Gray & White

Voltage : 230 Volt (v)

Features : Accurate results, Robust construction, Efficient working

Product Type : Notch Broaching Machine

Usage : specifically drafted for ferrous nonferrous material

|

EIE INSTRUMENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry