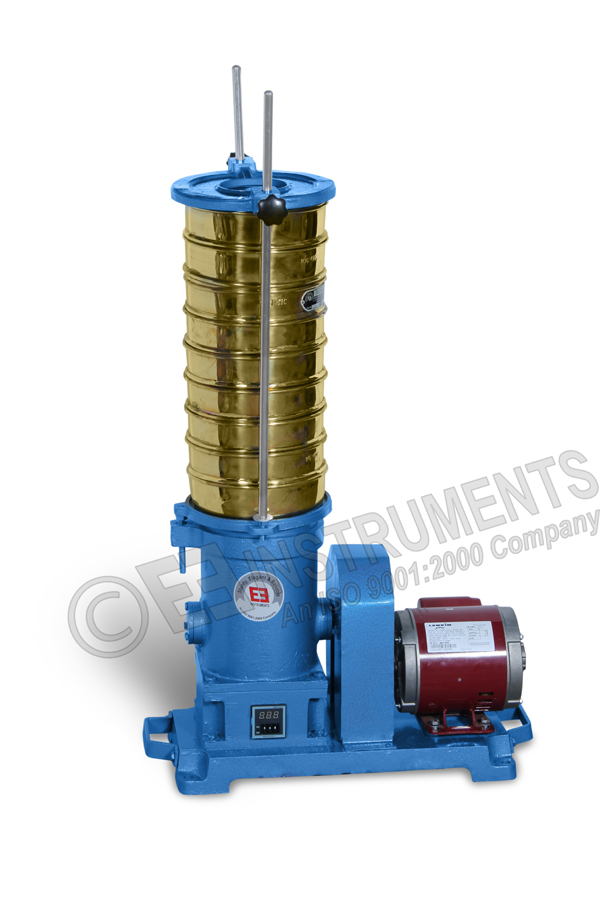

Gyratory Sieve Shaker

Gyratory Sieve Shaker Specification

- Features

- Accurate results, Robust construction, Efficient working

- Operate Method

- Electric

- Weight

- 57 Kilograms (kg)

- Voltage

- 220/230 Volt (v)

- Automation Grade

- Semi Automatic

- Usage

- Industrial

- Product Type

- Gyratory Sieve Shaker

- Color

- Blue

- Dimension (L*W*H)

- 610 X 410 X 450 (L X W X D) mm Millimeter (mm)

- Machine Weight

- 57 Kilograms (kg)

Gyratory Sieve Shaker Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- Ahmedabad

- Payment Terms

- Cash Against Delivery (CAD), Letter of Credit (L/C), Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 100 Pieces Per Month

- Delivery Time

- 4 Week

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Box / Corrugated Box

- Main Domestic Market

- All India

- Certifications

- ISO 9001 : 2015

About Gyratory Sieve Shaker

Salient Features:

- Carries upto 7 sieves of either 200mm or 300mm diameter in single adaptor.

- The sieve table does not rotate, but is inclined from the vertical axis.

- The direction of inclination changes progressively in clockwise direction.

- If the stop pin below the table is removed, the shaker can have a rotary motion.

- In addition to this gyratory motion of the table, thereis an upward and downward movement ensuring that eachsquare cm of the sieve is utilized.

- A pair of rods and a holder is supplied along with the main unit.

- The holder can be fixed on top of the upper most sieves, and thus the sieve set is firmly held.

- Suitable for operation on 230 volts, 50 cycles single phase A.C. Supply.

-

Further details availableon our website.

The Price mentioned here are subject to change as per the capacity,specifications and application of the user.

Efficient Particle Separation

Designed for industrial environments, the Gyratory Sieve Shaker provides rapid and accurate separation of particles. Its gyratory action ensures uniform movement of the sieves for reliable sample analysis, optimizing laboratory workflow and material processing.

Durable Construction and User-Friendly Operation

With its sturdy steel frame, the shaker withstands frequent use and heavy workloads. The accessible controls and intuitive design enhance convenience, making it suitable for regular laboratory or industrial tasks without excessive training.

FAQs of Gyratory Sieve Shaker:

Q: How does the Gyratory Sieve Shaker operate within an industrial environment?

A: The Gyratory Sieve Shaker functions by imparting a gyratory motion to stacked sieves, ensuring uniform material separation and precise particle analysis in industrial settings. It operates seamlessly on a 230 Volt power supply.Q: What materials and industries commonly use this sieve shaker?

A: This machine is widely utilized in construction, pharmaceuticals, mining, and chemical industries for testing, grading, and separating granular materials, powders, and fine samples.Q: When should I use the Gyratory Sieve Shaker for my laboratory tests?

A: Use the Gyratory Sieve Shaker whenever precise particle size distribution or material gradation is required, particularly during quality control, material verification, or research and development phases.Q: Where is the Gyratory Sieve Shaker typically installed?

A: It is commonly installed in laboratories, production facilities, and quality control departments within industrial plants, where material testing and analysis are routine procedures.Q: What is the process for using the Gyratory Sieve Shaker?

A: Place the desired test sieves in the shaker stack, load your material sample, secure the assembly, and activate the device. The machine moves the sieves in a gyratory pattern, facilitating effective particle separation.Q: How does using this machine benefit industrial operations?

A: Utilizing the Gyratory Sieve Shaker increases analytical efficiency, ensures consistent material quality, and reduces manual errors, making industrial processes more reliable and cost-effective.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

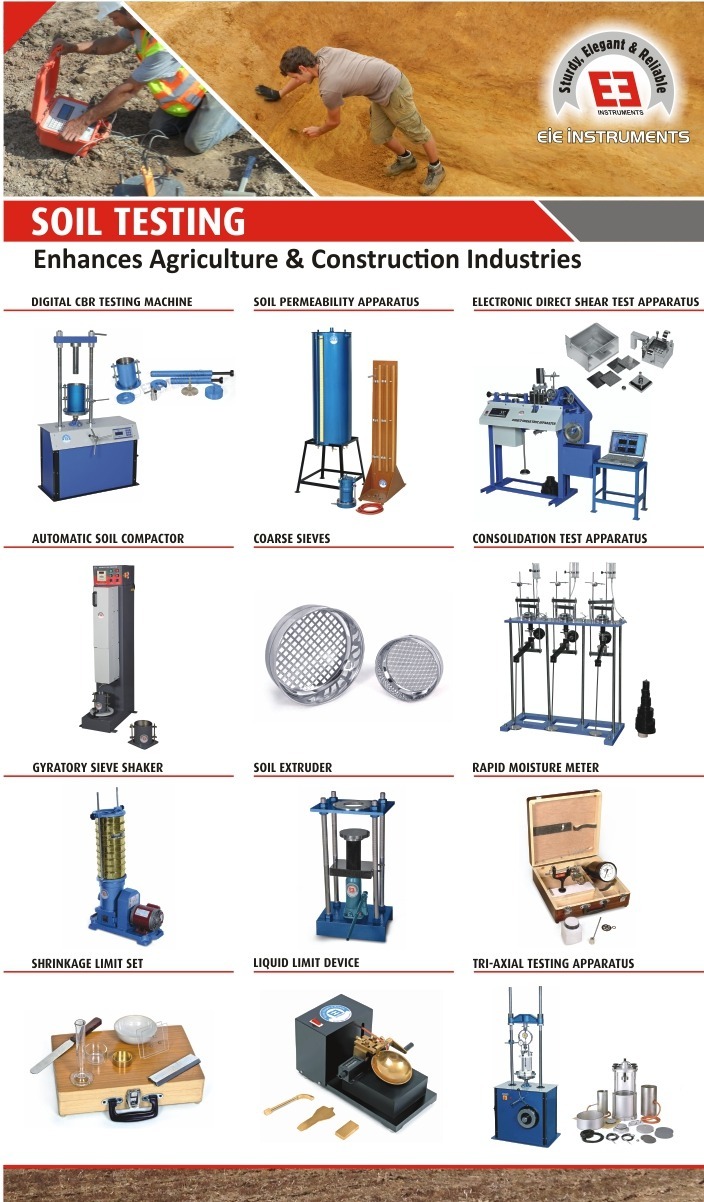

More Products in Aggregate Testing Equipments Category

Aggregate Testing Equipment

Price 1.00 INR / Piece

Minimum Order Quantity : 1

Application : Aggregate strength and durability testing

Automation Grade : Automatic

Features : Corrosionresistant, robust design, userfriendly

Capacity : 5 kg to 50 kg depending on accessory

ACCELERATED AGGREGATE (ROADSTONE) POLISHING MACHINE

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Application : Accelerated Polishing Machine. Specimens are manufactured in accurately machined and matched moulds; they are then removed from the moulds and located on the Road wheel.

Automation Grade : SemiAutomatic

Features : Heavy duty, low maintenance, corrosion resistant

Capacity : 14 specimens per set

Jaw Crusher

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Application : Crushing of minerals, ores, and hard materials

Automation Grade : SemiAutomatic

Features : Heavy duty construction, adjustable output size, high crushing efficiency

Capacity : 350 TPH

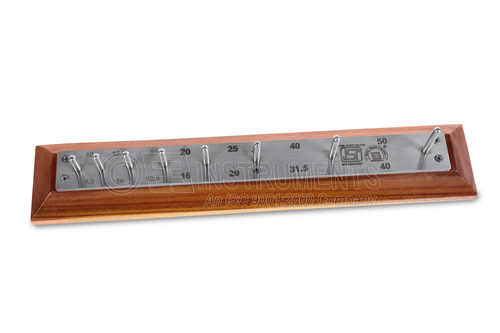

ISI Marked - Length Gauge

Price 3000 INR / Piece

Minimum Order Quantity : 1 Piece

Application : This instrument is used to determine the elongation index of aggregates

Automation Grade : Manual

Features : Six hardened steel pins for aggregate measurement, ISI Marked, corrosion resistant

Capacity : Single Specimen

|

EIE INSTRUMENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry