Flexural Attachment For Semi Automatic

Price 1.00 INR/ Piece

Flexural Attachment For Semi Automatic Specification

- Accuracy

- 1% of indicated value

- Display Type

- Digital LCD Display

- Temperature

- Operating Temperature: 5C to 40C

- Interface Type

- RS232 interface

- Application

- Bending and flexure testing of cement, mortar, or similar specimens

- Response Time

- <1 second

- Max Height

- 210 mm

- Hardness

- High-grade steel, HRC 55

- Automation Grade

- Semi-Automatic

- Specimen Size

- 40 mm x 40 mm x 160 mm

- Mounting Type

- Compatible with universal testing machines

- Number of Specimens

- Single Specimen

- Frequency

- 50 Hz

- Resolution

- 0.1 N

- Test Range

- 0-1000 N

- Power Supply

- 220 V AC, 50 Hz

- Operating Voltage

- 220 V AC

- Port Size

- Standard 10 mm fitting

- Features

- Corrosion-resistant finish, robust build, precise measurement

- Humidity

- Relative Humidity 20-80%

- Equipment Type

- Flexural Testing Attachment

- Measuring Range

- 0-1000 N

- Usage

- Industrial laboratory use

- Capacity

- Up to 1000 N

- Machine Weight

- Approx. 18 kg

- Test Speed

- 50 mm/min (adjustable)

- Test Width

- 70 mm

- Test Stroke

- Up to 100 mm

- Control Mode

- Semi-Automatic

- Maintenance

- Low maintenance design

- Movement Type

- Linear, guided

- Finish

- Smooth powder coated

- Load Application

- Central point

- Fixture Type

- Three-point loading

- Safety

- Overload protection

- Ambient Light Tolerance

- Up to 1000 lux

- Compliance

- Conforms to IS 516, ASTM C78

- Calibration

- Factory calibrated, certification included

Flexural Attachment For Semi Automatic Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- Ahmedabad

- Supply Ability

- 150 Pieces Per Year

- Delivery Time

- 4 Week

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden packing with strong base

- Main Export Market(s)

- Australia, Middle East, South America, Asia, Africa

- Main Domestic Market

- All India

- Certifications

- ISO 9001 : 2015

About Flexural Attachment For Semi Automatic

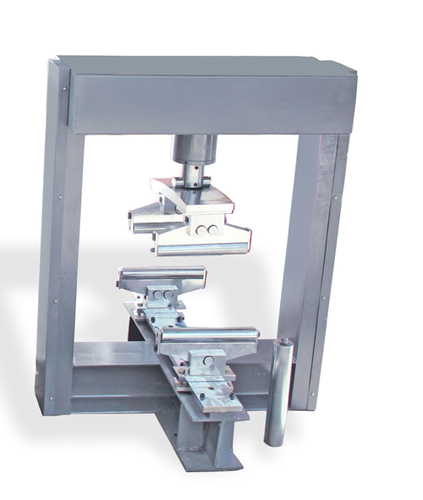

Flexural Attachment For Semi Automatic Ctm is included with different functional features such as automatic load release facility and others. It allows for a simple transmission of data and a highly functional loading unit. It has support for elementary data transmission over large distances. This is apt for efficient testing and provides accurate measurement on various grounds. Flexural Attachment For Semi Automatic Ctm provides accurate measurement of flexural strength and delivers operation to the required pace rate.Precision Flexure Testing Made Simple

Engineered for accuracy, the Flexural Attachment supports three-point bending tests on cement or mortar specimens with digital precision. Its linear, guided movement ensures uniform testing, while factory calibration provides immediate, dependable results. The smooth powder-coated finish and robust build guarantee both durability and a clean appearance, meeting demanding laboratory environments.

Compliance and Reliability in Every Test

This equipment surpasses industry benchmarks, strictly following IS 516 and ASTM C78 standards. Factory calibration with provided certification secures traceable, credible results each time. Built-in overload protection and low-maintenance construction reflect its focus on long-term operational reliability and user safety.

FAQs of Flexural Attachment For Semi Automatic:

Q: How does the Flexural Attachment ensure accurate bending and flexure testing?

A: The attachment utilizes a three-point central loading fixture, precise linear guided movement, digital LCD display, and is factory calibrated to deliver results with 1% accuracy and 0.1 N resolution.Q: What specimens can be tested with this equipment?

A: This device is specifically designed for single specimen testing of cement, mortar, and similar materials, accommodating specimen sizes of 40 mm x 40 mm x 160 mm.Q: When should the Flexural Attachment be used in industrial laboratories?

A: It is ideal for routine quality control or research applications demanding consistent bending and flexural strength assessments in compliance with IS 516 and ASTM C78.Q: Where can this attachment be mounted?

A: The attachment is compatible with standard universal testing machines and can be conveniently integrated in laboratory setups that use such equipment.Q: What is the operational process for conducting a test with this attachment?

A: Place the specimen on the three-point fixture, configure test speed and stroke via digital controls, and initiate the semi-automatic test. The overload protection and digital display provide safe operation and real-time results.Q: How does the low-maintenance design benefit users?

A: Robust construction with corrosion-resistant finish minimizes maintenance demands, reducing downtime and service costs while prolonging operational life.Q: What are the main benefits of factory calibration and certification?

A: Factory calibration ensures the device delivers highly accurate measurements right from installation, while certification provides documented compliance for audits and regulatory requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Concrete Testing Equipment Category

Ultrasonic Concrete Tester

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Features : Portable, high accuracy, realtime display, automatic data storage

Frequency : 40 kHz (transducer)

Usage : Concrete compressive strength and quality evaluation

Automation Grade : Semiautomatic

APPARATUS FOR THE MEASUREMENT OF BEAM CMOD AND TOUGHNESS OF FRC

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Features : Fully automatic, Servo control, Data logging, High precision load cell

Frequency : 50 Hz

Usage : Concrete Testing Equipment

Automation Grade : Fully Automatic

CONCRETE PERMEABILITY TESTER - 6 CELL - COMPACT

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Features : Compact, multicell, corrosion resistant finish

Frequency : 50 Hz

Usage : Laboratory concrete test

Automation Grade : Manual

Accelerated Carbonation Chamber

Price 700000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Features : Accurate results, Robust construction, Efficient working

Frequency : 5060 Hertz (HZ)

Usage : Concrete Testing Equipment

Automation Grade : Semi Automatic

|

EIE INSTRUMENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry