Accelerated Carbonation Chamber

Price 700000.00 INR/ Piece

Accelerated Carbonation Chamber Specification

- Power Supply

- 230 Volts, 50 Hz, Single Phase, AC Supply

- Usage

- Concrete Testing Equipment

- Product Type

- ACCELERATED CARBONATION CHAMBER-INNER S.S.-REFRIGERATED-60X60X60 CM-216 LITERS

- Weight

- 176 Kilograms (kg)

- Machine Weight

- 176 Kilograms (kg)

Accelerated Carbonation Chamber Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- Ahmedabad

- Payment Terms

- Cash Against Delivery (CAD), Letter of Credit (L/C), Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 100 Pieces Per Month

- Delivery Time

- 4 Week

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Box / Corrugated Box

- Main Domestic Market

- All India

- Certifications

- ISO 9001 : 2015

About Accelerated Carbonation Chamber

Compliance With Following International Standards:

EN 13295, ISO 192012: 2015 -Part 12, EN 13295

Accelerated Carbonation Chamber is useful for Accelerated Carbonation test of Concrete.

Further details available on our website.

Price and specifications mentioned here are subject to change as per the application, customer requirements and prevailing market conditions. Please refer to us for the final rates and offer.

Precision PLC Control and Computerization

This Accelerated Carbonation Chamber incorporates a PLC-controlled system, paired with computerized automation, to deliver unparalleled consistency and accuracy during concrete testing. The system ensures precise management of test cycles and environmental parameters, minimizing human error and facilitating detailed data collection.

Durable Steel Construction and Optimal Dimensions

Crafted from high-quality steel and measuring 600 x 600 x 600 mm, the chamber is engineered for heavy-duty use in any laboratory or industrial setting. The compact yet spacious interior allows for various specimen sizes, ensuring versatility in testing different concrete samples.

Reliable and User-Friendly Operation

Operating on a standard 230V AC power supply, the chamber is straightforward to install and use. Automated functions streamline test setup and execution, saving valuable time and reducing manual intervention. Its clear interface makes it accessible for users of all experience levels.

FAQs of Accelerated Carbonation Chamber:

Q: How does the Accelerated Carbonation Chamber work?

A: The chamber accelerates the carbonation process in concrete specimens by precisely controlling temperature, humidity, and CO levels through its PLC system. This simulates long-term carbonation in a compressed timeframe for efficient durability analysis.Q: What is the primary usage of this equipment?

A: The Accelerated Carbonation Chamber is mainly used for testing the carbonation resistance of concrete. This helps researchers and quality controllers assess durability and longevity in various construction applications.Q: When should I perform carbonation testing with this chamber?

A: Carbonation testing is best performed during research, routine quality checks, or when evaluating new concrete mixes for structural projects. Early testing helps identify potential durability issues prior to large-scale application.Q: Where can the Accelerated Carbonation Chamber be used?

A: It is suitable for use in concrete testing laboratories, research institutions, cement plants, and construction quality control departments throughout India and abroad.Q: What is the process for setting up and operating the chamber?

A: Simply connect the chamber to a 230V, 50 Hz single-phase AC power supply, place the concrete specimens inside, set the required test parameters via the PLC control interface, and start the automated test cycle. The chamber handles environmental regulation for accurate results.Q: What benefits does the computerized control system offer?

A: Computerized and PLC controls ensure high repeatability, accurate data acquisition, and easy recall of testing cycles. This reduces operator workload and ensures standardization across multiple tests.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Concrete Testing Equipment Category

Flexural Attachment For Semi Automatic

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Industrial laboratory use

Application : Bending and flexure testing of cement, mortar, or similar specimens

Machine Weight : Approx. 18 kg

Automation Grade : SemiAutomatic

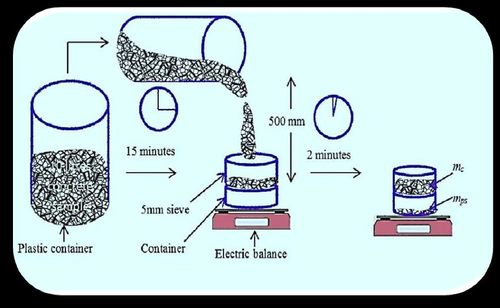

Sieve Segregation Test Set

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Concrete Testing Equipment

Application : Concrete Segregation Test

Machine Weight : 18 kg

Automation Grade : Manual

APPARATUS FOR THE MEASUREMENT OF BEAM CMOD AND TOUGHNESS OF FRC

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Concrete Testing Equipment

Application : Flexural & Toughness Testing of FRC (Fibre Reinforced Concrete) Beams

Machine Weight : 300 Kilograms (kg)

Automation Grade : Fully Automatic

CONCRETE PERMEABILITY TESTER - 6 CELL - COMPACT

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Laboratory concrete test

Application : Determines permeability of concrete

Machine Weight : Approx 50 kg

Automation Grade : Manual

|

EIE INSTRUMENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry