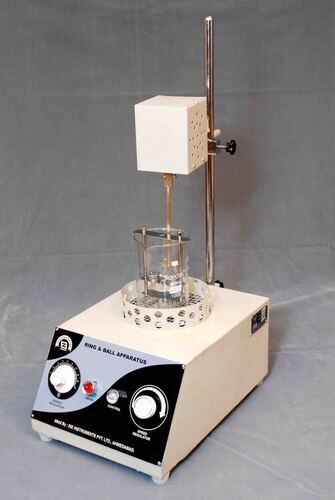

RING AND BALL APPARATUS ELECTRICALLY OPERATED

Price 1.00 INR/ Piece

RING AND BALL APPARATUS ELECTRICALLY OPERATED Specification

- Humidity

- Ambient

- Temperature

- Up to 100C

- Mounting Type

- Tabletop

- Product Type

- Ring and Ball Apparatus Electrically Operated

- Power Supply

- 230V AC, 50 Hz

- Resolution

- 0.1C

- Automation Grade

- Semi-automatic

- Frequency

- 50 Hz

- Operating Voltage

- 230V AC

- Interface Type

- Manual control switches

- Response Time

- Immediate

- Max Height

- Approx. 250 mm

- Accuracy

- 0.5C

- Test Range

- Softening point typically 30C to 100C

- Usage

- Petroleum Testing Equipment

- Features

- Electrically heated bath, Two steel balls, Brass rings, Temperature control

- Number of Specimens

- 2

- Port Size

- Standard water bath port

- Specimen Size

- Ring inner diameter: 17 mm, Ball diameter: 9.5 mm

- Application

- This apparatus is meant for determinationofsofteningpoint of bituminous materials

- Display Type

- Analog thermometer/optional digital

- Measuring Range

- 30C to 100C

- Gas Pressure

- Ambient

- Machine Weight

- Approx. 2.8 kg

- Test Speed

- Manual dip

- Test Width

- Standard ring diameter: 28 mm

- Control Mode

- Electrically Operated

- Ring Material

- Brass

- Heating Element

- Immersion type, corrosion resistant

- Water Bath Capacity

- Approx. 600 ml

- Ball Composition

- Plated steel

- Calibration Method

- Manual with reference standard

- Bath Material

- Borosilicate glass or heat-resistant fiber

- Conformance

- IS: 1205, ASTM D36, IP 58

- Equipment Type

- Ring and Ball Apparatus Electrically Operated

- Temperature Sensor

- Mercury or alcohol thermometer

- Safety

- Fused power input, grounded body

- Accessories

- Ball centering guide, ring holder, beaker

RING AND BALL APPARATUS ELECTRICALLY OPERATED Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 100 Pieces Per Month

- Delivery Time

- 4 Week

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Box / Corrugated Box

- Certifications

- ISO 9001 : 2015

About RING AND BALL APPARATUS ELECTRICALLY OPERATED

Also called Softening Point Apparatus. This apparatus is meant for determinationofsofteningpoint of bituminous materials according to IP 58 and IS 1205. Softening point is that temp. at which the specimen under test becomes soft enough to allow a steel ball of specific dimension to fall a required distance under test condition. Theapparatus consist of Glass beaker of heat resistant glass of internal dia 8.5 cm x 12 cm depth, Two steel balls each of 9.5mm dia, Two tapered brass rings, Two ball guides, ring stand and a MOTORIZED stirrer. Electrical motorized with heater andtemp. regulator with DC motor

Further details available on our website.

The Price mentioned here are subject to change as per the capacity,specifications and application of the user.

Precision Petroleum Testing

Designed for accurate measurement of softening points in bituminous materials, this apparatus combines electrically-heated immersion technology with a high-quality glass/fiber bath. It offers precise control and reliable repeatability, fulfilling IS: 1205, ASTM D36, and IP 58 requirements. The compact tabletop unit accommodates two specimens, provides rapid response, and allows manual operation, making it ideal for petroleum product laboratories.

Robust Construction and Safety Features

The apparatus is made with a corrosion-resistant heating element and a durable bath of borosilicate glass or heat-resistant fiber. Brass rings and plated steel balls ensure longevity, while safety is prioritized with fused power input and a grounded body. Operating at 230V AC and 50 Hz, its suitable for various ambient conditions and features accessories for convenient handling, including a ball centering guide and ring holder.

FAQs of RING AND BALL APPARATUS ELECTRICALLY OPERATED:

Q: How does the electrically operated Ring and Ball Apparatus function in determining softening points?

A: The apparatus heats a bituminous sample in a controlled water bath, allowing a plated steel ball to sink through the softened material. The apparatus records the temperature at which the ball contacts a defined point, indicating the materials softening point.Q: What types of testing standards does this equipment conform to?

A: This Ring and Ball Apparatus is compliant with IS: 1205, ASTM D36, and IP 58. These standards specify methods for measuring the softening point of bitumen and similar materials, ensuring accuracy and reliability for international testing requirements.Q: Where is the apparatus typically used, and what are its main applications?

A: It is commonly used in petroleum and asphalt testing laboratories, research facilities, and quality control departments. Its primary application is to determine the softening point of bituminous and thermoplastic substances, which is critical for assessing suitability in paving or roofing.Q: What features ensure accuracy and safety during operation?

A: Accuracy is maintained through an immersion-type, corrosion-resistant heater and a high-resolution thermometer (0.1C), with 0.5C measurement accuracy. Safety is supported by a fused, grounded power input and robust construction, minimizing operational risks.Q: How is calibration performed on this apparatus?

A: Calibration is carried out manually using a reference standard. The temperature sensor (either a mercury or alcohol thermometer) is checked against this standard to ensure precise readings during every test cycle.Q: What accessories are included, and how do they support the testing process?

A: Essential accessories such as the ball centering guide, ring holder, and a beaker are included. These components facilitate accurate placement of balls and rings, enhance measurement precision, and simplify the overall test procedure.Q: What are the benefits of using a semi-automatic, electrically operated setup for ring and ball testing?

A: The semi-automatic design and electric heating allow for consistent temperature control, reduced manual intervention, immediate response, and reliable repeatabilitysignificantly improving efficiency and confidence in petroleum testing results.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

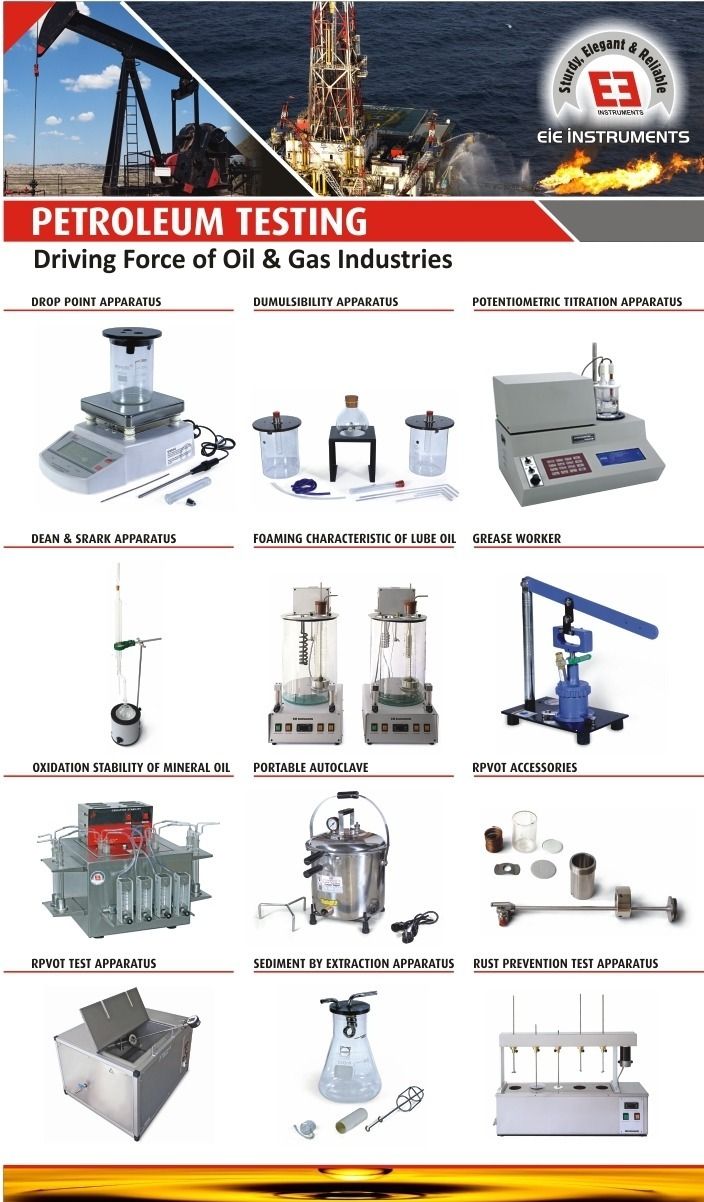

More Products in Petroleum Testing Equipments Category

Evaporation Loss of Lubricating Grease and Oil- Ip 183

Minimum Order Quantity : 1 Piece

Operate Method : Electric

Usage : Laboratory

Features : Accurate results, Robust construction, Efficient working

Voltage : 230 Volt (v)

Automation Grade : Semi Automatic

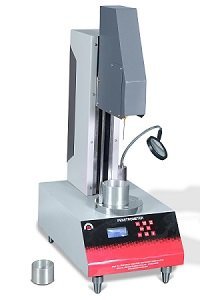

Fully Automatic Universal Penetrometer

Minimum Order Quantity : 1 Piece

Operate Method : Electric

Usage : For Bitumen Testing

Features : Accurate results, Robust construction, Efficient working

Voltage : 230 Volt (v)

Automation Grade : Automatic

Grease Worker Double Cup Model

Minimum Order Quantity : 1 Piece

Operate Method : Electric

Usage : Laboratory

Features : Accurate results, Robust construction, Efficient working

Voltage : 220/240 Volt (v)

Automation Grade : Automatic

Petroleum Testing Equipments

Minimum Order Quantity : 1 , , Piece

Operate Method : Electric

Usage : Industrial

Features : Accurate results, Robust construction, Efficient working

Voltage : 220/240 Volt (v)

Automation Grade : Semi Automatic

|

EIE INSTRUMENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry