PYROLYTIC CLEANING OVEN

Price 1.00 INR/ Piece

PYROLYTIC CLEANING OVEN Specification

- Usage

- Bitumen Testing Equipment

- Dimension (L*W*H)

- 31 x 37 x 60

- Product Type

- Pyrolytic Cleaning Oven

- Weight

- 250 Kilograms (kg)

- Equipment Materials

- Power Coated / Painted / Chrome Plated

- Power

- 240 V, 50 Hz., Single Phase

- Application

- The Pyrolytic Oven is used for performing safe, solvent-free cleaning of asphalt and other organic residues from glass and labware.

- Warranty

- 1 Year

PYROLYTIC CLEANING OVEN Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 100 Pieces Per Month

- Delivery Time

- 4 Week

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Box / Corrugated Box

- Certifications

- ISO 9001 : 2015

About PYROLYTIC CLEANING OVEN

The Pyrolytic Oven is used for performing safe, solvent-free cleaning of asphalt and other organic residues from glass and labware. Even trace residues of organic contaminants from asphalt, injection molding, and organic chemistry applications are removed, leaving lab equipment ultra-clean for critical testing This cost-effective, fully automatic method saves time and creates a safer, more efficient lab environment. Costs and risks of hazardous waste handling and disposal, glass breakage, and labor are reduced or eliminated. Lab technicians no longer need to rely on scraping, wire brushing, or hand heating to clean bitumen or other organic residues from the glassware. Operators can simply place everything in their pyrolytic oven, press start, and allow the machine to do the work. This not only reduces mess, but saves time and creates a safer, more efficient lab environment. Maximum oven temperature is 482C and cleaning temperatures range from 426C to 482C to burn off organic contaminants, leaving behind only carbonized residue, which can be easily removed.

Further details available on our website.

Price and specifications mentioned here are subject to change as per the application, customer requirements and prevailing market conditions. Please refer to us for the final rates and offer.

Safe and Solvent-Free Cleaning

This Pyrolytic Oven offers a solvent-free process, using only controlled heat to break down asphalt and organic residues. The enclosed design ensures a safe working environment for users, while the absence of chemical solvents reduces health and environmental risks commonly associated with traditional cleaning methods.

Rugged Build for Laboratory Demands

Fabricated from powder-coated, painted, and chrome-plated materials, the oven is engineered to withstand the rigors of daily laboratory operation. Its solid construction ensures long-lasting performance, while the compact footprint makes it a suitable fit for most laboratory settings involved in bitumen testing.

FAQs of PYROLYTIC CLEANING OVEN:

Q: How does the pyrolytic cleaning process work in this oven?

A: The oven reaches high temperatures to thermally decompose and vaporize asphalt and other organic residues from glass and labware. This process breaks down contaminants without the need for chemical solvents, ensuring safe and thorough cleaning.Q: What are the primary applications of the Pyrolytic Cleaning Oven?

A: This oven is specifically designed for cleaning glassware and equipment used in bitumen testing laboratories. It effectively removes asphalt and organic build-up, making it ideal for maintaining clean and residue-free labware.Q: When should I use the pyrolytic oven for cleaning laboratory equipment?

A: You should use the oven whenever glass or labware accumulates asphalt or organic residues that cannot be easily removed through conventional washing. Regular use helps maintain equipment in optimal condition for precise testing results.Q: Where is the Pyrolytic Cleaning Oven manufactured and supplied from?

A: The oven is manufactured, exported, and supplied by experienced providers in India, ensuring adherence to quality standards suitable for international laboratory requirements.Q: What are the benefits of pyrolytic cleaning compared to traditional solvent methods?

A: Pyrolytic cleaning eliminates the need for hazardous chemicals, improving user safety and environmental compliance. It also offers thorough, uniform cleaning, reducing the risk of contamination in subsequent tests.Q: What maintenance does the oven require for optimal operation?

A: Regular inspection, exterior cleaning, and checking for residue inside the chamber are recommended. Always follow the manufacturers guidelines to ensure safe and reliable performance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

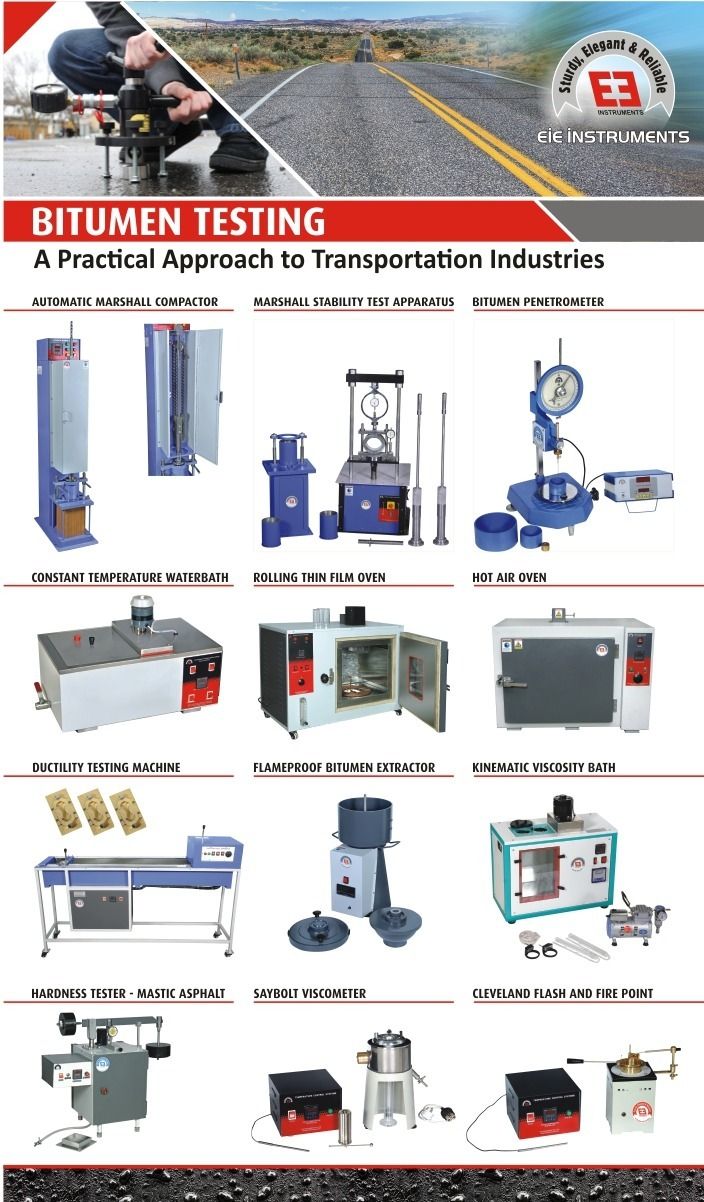

More Products in Bitumen Testing Equipments Category

Bitumen Testing Equipments

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Application : Testing of Bitumen and Asphalt for Road Construction

Warranty : Yes

Equipment Materials : HighGrade Steel with Protective Coating

Product Type : Bitumen Testing Equipments

AUTOMATIC WHEEL TRACK TESTER - SINGLE TEST

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Application : This instrument is designed and manufactured in accordance with the requirements of T07192011 "Asphalt Mixture Rutting Test" in the industry standard

Warranty : 1 Year

Equipment Materials : Power Coated / Painted / Chrome Plated

Product Type : AUTOMATIC WHEEL TRACK TESTER SINGLE TEST WITH MOULDING MACHINE

Modified Marshal Stability Testing Machine - 6" Dia With Proving Ring & Dial Gauge

Price 75000 INR / Piece

Minimum Order Quantity : 1 Piece

Application : For Testing Bituminous Mix Stability and Flow Value

Equipment Materials : Mild Steel Body, Chrome Plated & Powder Coated Components

Hardness Tester for Bitumen Mastic Asphalt

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Application : Hardness tester for Mastic Asphalt has been fabricated to meet the essential requirements of IS 1195 1968 in finding out the Hardness Number of mastic asphalt.

Warranty : 1 Year

Equipment Materials : Power Coated / Painted / Chrome Plated

Product Type : Bitumen Testing Equipment

|

EIE INSTRUMENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry