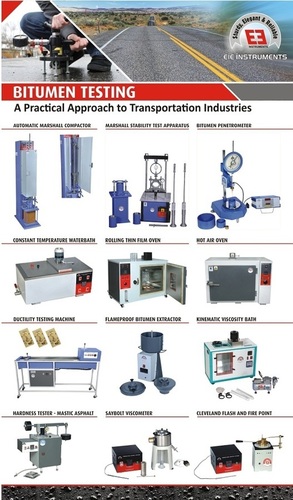

Bitumen Testing Equipments

Price 1.00 INR/ Piece

Bitumen Testing Equipments Specification

- Shape

- Rectangular/Cylindrical (Depends on test method)

- Power Supply

- Electric

- Temperature Resistance

- Up to 200C depending on test method

- Accuracy

- 0.1C (Temperature); 0.5% (Measurement)

- Control Type

- Digital/Manual, as per model

- Display Type

- Digital/Analog (as per equipment)

- Speed Range

- 0120 rpm (As per equipment specification)

- Features

- Corrosion Proof, Rugged Design, User Friendly, Long Service Life, Automatic Operation

- Heating Capacity

- Customized as per test requirement

- Glass Type

- Borosilicate (if applicable)

- Type

- Automatic

- Dimension (L*W*H)

- Customized (As per model and requirement)

- Equipment Type

- Bitumen Testing Equipments

- Equipment Materials

- High-Grade Steel with Protective Coating

- Power

- 220240V, 50/60Hz

- Voltage

- 220V

- Application

- Testing of Bitumen and Asphalt for Road Construction

- Capacity (Ltr)

- Varies by Model (Available from 5L to 50L)

- Sample Compatibility

- Various grades of bitumen and asphalt

- Finish

- Powder Coated / Polished

- Operating Temperature

- Ambient to 200°C

- Accessories Included

- Standard set of testing accessories

- Compliance Standards

- IS / ASTM / AASHTO Standards

- Safety Features

- Over-temperature protection, Shock proof body

Bitumen Testing Equipments Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- Ahmedabad

- Payment Terms

- Letter of Credit (L/C), Cash Against Delivery (CAD), Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 100 Pieces Per Day

- Delivery Time

- 4 Week

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden packing with strong base

- Main Export Market(s)

- Australia, Middle East, South America, Asia, Africa

- Main Domestic Market

- All India

- Certifications

- ISO 9001 : 2015

About Bitumen Testing Equipments

Bitumen Testing Equipments are provided with several business requirements. These are equipped with all up-to-the-minute facilities, required for designing the testing equipments. In this way, these provide high level of manufacturing industry. Bitumen Testing Equipment is provided with high mechanical strength, smooth operation, bonding, shock absorbency etc. These assist in making robust as well as classic highways. Also, these provide accurate results and boast of advanced mechanical strength.

Product details

| Material | Mild Steel |

| Usage/Application | Laboratory |

| Model Name/Number | EIE |

| Packaging Type | Wooden Box |

| Brand | EIE |

Advanced Design for Reliable Bitumen Testing

Bitumen Testing Equipments are engineered with automatic operation and user-friendly interfaces, ensuring consistent and accurate results. The combination of corrosion-proof steel construction and over-temperature protection enhances safety and durability. Customizable dimensions and capacities allow for the perfect fit in any laboratory or onsite roadwork environment. Whether the display is digital or analog, the clear readout, along with rugged design, streamlines your workflow and improves reliability.

Compliant and Versatile for All Testing Needs

Strict adherence to IS, ASTM, and AASHTO standards guarantees international compatibility and confidence in results. Equipment supports various bitumen and asphalt grades, with specialized glass type options for enhanced thermal resistance. Whether you are a manufacturer, exporter, service provider, supplier, or trader, our versatile range can be tailored to specific applications and test methods across India and globally.

FAQs of Bitumen Testing Equipments:

Q: How do Bitumen Testing Equipments ensure measurement accuracy?

A: These equipments feature precise temperature control (0.1C) and measurement accuracy (0.5%) through advanced digital or manual controls, ensuring reliable outcomes for all bitumen and asphalt testing procedures.Q: What safety features are included in these testing equipments?

A: Safety is prioritized with over-temperature protection, shock-proof bodies, and corrosion-proof materials. These features safeguard users and equipment during high-temperature operations up to 200C.Q: When should I use the automatic function on the Bitumen Testing Equipment?

A: Automatic operation is recommended for routine and high-volume testing to facilitate consistent results, minimize manual errors, and streamline workflow within laboratory or field environments.Q: Where is this equipment commonly used and who can benefit from it?

A: The equipment is extensively used in laboratories, construction sites, and research facilities for road construction. It benefits manufacturers, exporters, service providers, suppliers, and traders involved in quality control and material testing.Q: What process is followed for testing bitumen or asphalt samples?

A: Users place samples in the equipment, set desired temperature and speed controls, and initiate automated or manual testing protocols. Standard accessories and borosilicate glass components support accurate and safe operations.Q: How does the equipment accommodate different sample sizes and grades?

A: With customizable capacities from 5L to 50L and adaptability to various grades of bitumen and asphalt, the equipment caters to diverse testing needs, including specialized model dimensions and configurations.Q: What benefits do the included accessories provide during operation?

A: Standard testing accessories enhance procedural efficiency, support multiple testing methods, and ensure all essential components are available for immediate use, reducing setup time and increasing productivity.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Bitumen Testing Equipments Category

APP. FOR DETERMINATION OF STORAGE STABILITY

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : APP. FOR DETERMINATION OF STORAGE STABILITY

Application : For Storage Stability

Usage : Bitumen Testing Equipment

Dimension (L*W*H) : 550 x 330 x 360 mm

Hardness Tester for Bitumen Mastic Asphalt

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : Bitumen Testing Equipment

Application : Hardness tester for Mastic Asphalt has been fabricated to meet the essential requirements of IS 1195 1968 in finding out the Hardness Number of mastic asphalt.

Usage : Bitumen Testing Equipment

Dimension (L*W*H) : 860 X 365 X 625 ( L X W X H ) MM

Fraass Breaking Point apparatus

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : FRAASS BREAKING ASSEMBLY WITH ACCESSORIES

Application : Used for determining the breaking point of solid and semisolid bitumen

Usage : Bitumen Testing Equipment

Dimension (L*W*H) : 5" x 5" x 20" [LxWxH] Inch (in)

Asphalt Content Gauge

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : ASPHALT CONTENT OVEN(ASPHALT IGNITION OVEN)

Application : For the accurate determination of asphalt content

Usage : Bitumen Testing Equipment

Dimension (L*W*H) : 800 X 800 X 1600 (L X W X D) mm

|

EIE INSTRUMENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry