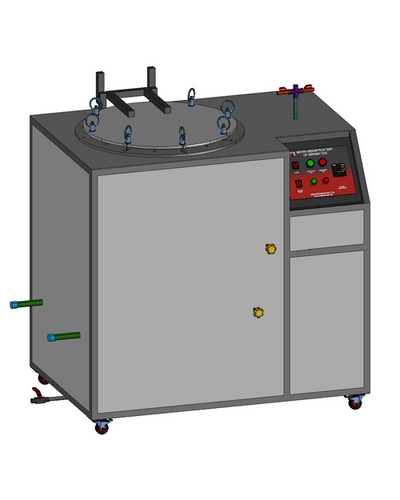

MOR TESTING MACHINE FOR CERAMIC BAR

Price 1.00 INR/ Piece

MOR TESTING MACHINE FOR CERAMIC BAR Specification

- Response Time

- Less than 2 seconds

- Specimen Size

- Length: 150300 mm, Width: Up to 100 mm, Thickness: Up to 25 mm

- Port Size

- Standard fitting for ceramic bar

- Automation Grade

- Semi-automatic

- Voltage

- 230 Volt (v)

- Humidity

- Up to 85% RH non-condensing

- Capacity

- 500 KGF Kg/hr

- Usage

- TILES AND CERAMICS TESTING EQUIPMENTS

- Number of Specimens

- 1 (at a time)

- Max Height

- 400 mm clearance under crosshead

- Accuracy

- 1%

- Mounting Type

- Floor standing

- Interface Type

- RS232/USB (Optional)

- Resolution

- 0.01 KGF

- Application

- Tiles, ceramic bar, and related material strength testing

- Measuring Range

- 0 500 KGF

- Features

- Overload protection, real-time digital reading, motorized operation

- Frequency

- 50 Hz

- Operating Voltage

- 230V AC

- Hardness

- Suitable for ceramic, porcelain, and vitrified samples

- Power Supply

- 230V AC, 50Hz

- Product Type

- MOR TESTING MACHINE FOR CERAMIC BAR

- Test Range

- 0 500 KGF

- Temperature

- 10C 40C (Operational)

- Display Type

- Digital LCD/LED Display

- Machine Weight

- Approx. 150 kg

- Test Speed

- 0.05 - 500 mm/min (adjustable)

- Test Width

- Up to 100 mm

- Test Stroke

- 0 - 250 mm

- Control Mode

- Automatic with manual override

- Safety Mechanism

- Emergency stop button and overload cutoff

- Equipment Type

- MOR TESTING MACHINE FOR CERAMIC BAR

- Result Output

- Digital printout or USB export (optional)

- Finish

- Powder coated corrosion resistant body

- Operating Environment

- Laboratory and industrial

- Crosshead Speed Adjustment

- Variable via control panel

- Load Measurement

- Electronic load cell based

MOR TESTING MACHINE FOR CERAMIC BAR Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 100 Pieces Per Month

- Delivery Time

- 4 Week

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Box / Corrugated Box

- Certifications

- ISO 9001 : 2015

About MOR TESTING MACHINE FOR CERAMIC BAR

Salient Features:

- Suitable to test Fired Bar

- Supplied with flexible platform and dedicated load cells

- Suitable for quiet and vibration free operations

- Suitable for MOR Test of Ceramic Tiles and Bars

- Direct reading possible in n/mm2

- Digital Model with LCD Display for easy readability

- Back light to observe the readings even in dark.

- Direct Display of Load / Collapsing Force and MOR Value

- Auto reverse facility upon sample failure

- Over load and Over travel protection facility

- Provision for emergency switch in case, if user wants tostop the load applicator at certain height

- With embedded push buttons operation on Digital panel

- Integrated AC drive in main controller as to control rate of loading through controller itself

- Equipped With 2 rubber coated rollers of 15 mm diameter

- Auto Calibration facility using standard Cast Iron Weights and standard code

Furtherdetails available on our website.

The Price mentioned here are subject to change as per the capacity,specifications and application of the user.

Reliable Load Measurement and Accuracy

Equipped with an advanced electronic load cell, the MOR Testing Machine delivers precise and real-time load measurements up to 500 KGF. An impressive accuracy of 1% and resolution down to 0.01 KGF ensures you get dependable results every time, meeting quality industry standards for tiles and ceramic products.

User-Friendly Operation and Versatility

The machine offers variable crosshead speeds adjustable between 0.05 to 500 mm/min, catering to diverse testing needs. Its intuitive control panel supports automatic operation with manual override, and result outputs are available via digital print or optional USB export, enhancing usability for both routine and specialized applications.

Enhanced Safety and Durability

Safety is prioritized with features like an emergency stop button and overload cutoff. The robust, powder-coated body resists corrosion, and the floor-standing design is suitable for heavy-duty industrial and laboratory use. Its design accommodates various specimen sizes, making it a versatile solution for comprehensive ceramic testing.

FAQs of MOR TESTING MACHINE FOR CERAMIC BAR:

Q: How does the MOR Testing Machine measure the strength of ceramic bars?

A: The MOR Testing Machine uses an electronic load cell to apply and accurately measure up to 500 KGF on ceramic bars or tiles. The digital display shows real-time load values, and results can be recorded via a paper printout or exported through a USB interface (optional).Q: What safety mechanisms are integrated into the machine?

A: This machine is equipped with an emergency stop button and overload cutoff system, safeguarding both the operator and specimens during testing. These features ensure immediate response to irregularities or overload conditions.Q: What specimen sizes and shapes can be tested on this machine?

A: The MOR Testing Machine accommodates one specimen at a time, with lengths between 150300 mm, widths up to 100 mm, and thicknesses up to 25 mm. It is tailored for testing ceramic bars, tiles, and related materials.Q: When and where should this machine be operated for optimal performance?

A: For best results, operate the machine in laboratory or industrial environments where the temperature is between 10C and 40C, with non-condensing humidity up to 85%. Proper ventilation and a stable power supply (230V AC, 50Hz) are recommended.Q: How is the test process controlled and monitored?

A: Operators can adjust crosshead speed through the control panel, select automatic mode, or use manual override for specific tasks. The digital display provides real-time test parameters and quick response times, supporting efficient testing workflows.Q: What are the main benefits of using this MOR Testing Machine?

A: Key benefits include precise strength measurement with high accuracy, reliable safety features, quick result outputs, and robust construction for resilience. It helps manufacturers ensure the quality and durability of ceramic and porcelain products.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Tiles and Ceramic Testing Equipments Category

Portable Gauge

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Application : Onsite measurement / inspection

Features : Lightweight, ergonomic, rechargeable, data hold

Automation Grade : Manual

Usage : Inspection, measurement

WATERBATH FOR WATER ABSORPTION TEST OF CERAMIC TILE

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Application : For water absorption test of ceramic tiles. The tiles will be placed vertically in the slots provided to conduct the water absorptions characteristic test.

Features : Inbuilt vacuum pump, Digital temperature control, Corrosionresistant stainless steel tank, Slot arrangement for vertical placement of tiles

Automation Grade : Manual / Semiautomatic

Usage : Tiles and Ceramics Testing Equipment

M.O.R. Testing Machine

Price 1.00 INR

Minimum Order Quantity : 1 Piece

Application : Flexural Strength / Modulus of Rupture test of ceramics, tiles, and bricks

Features : Heavyduty steel frame, Overload Protection, Adjustable Traverse Speed

Automation Grade : SemiAutomatic/Manual

Usage : Industrial

SHEAR BOND JIG-TENSILE METHOD

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Application : Shear Bond Jig tests for the shear strength test of dispersion adhesives

Features : Corrosionresistant, Easy operation, Sturdy design

Automation Grade : Manual / Semiautomatic

Usage : Tile Adhesive Testing

|

EIE INSTRUMENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry