Foaming Characteristics of Lubricating Oil -(Two Test Cylinder)

Foaming Characteristics of Lubricating Oil -(Two Test Cylinder) Specification

- Product Type

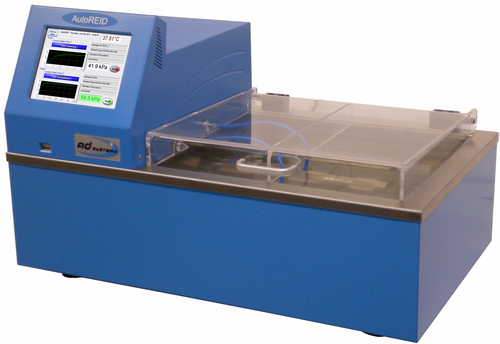

- FOAMING CHARACTERISTICS OF LUBRICATING OIL TWO TEST CYLINDERS SINGLE JAR

- Frequency

- 50-60 Hertz (HZ)

- Material

- Stainless Steel

- Automation Grade

- Semi Automatic

- Features

- Accurate results, Robust construction, Efficient working

- Operate Method

- Electric

- Power Supply

- 230 Volts, 50 Hz, Single phase, AC Supply

- Voltage

- 230 Volt (v)

- Usage

- PETROLEUM TESTING EQUIPMENTS

Foaming Characteristics of Lubricating Oil -(Two Test Cylinder) Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- Ahmedabad

- Supply Ability

- 100 Pieces, Piece Per Month

- Delivery Time

- 4 Week

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Box / Corrugated Box

- Main Domestic Market

- All India

- Certifications

- ISO 9001 : 2015

About Foaming Characteristics of Lubricating Oil -(Two Test Cylinder)

Construction Details

The complete assembly consists of following parts and accessories.

1)Foaming BathApparatus Glass jar with TWO Test Cylinders and combined Heating and Cooling arrangement

- Consists of constant temperature transparent glass heating jar bath

- Heating glass jar will be of Heat resistant material having height of 450 mm and Diameter of 300 mm

- The transparent heating test bath will be provided with top cover

- Tank cover will be having one hole, which allows 1000 ml cylinders to get through it

Furtherdetails available on our website.

The Price mentioned here are subject to change as per the capacity,specifications and application of the user.

Precision Testing for Lubricating Oil

This apparatus provides precise analysis of foaming characteristics in lubricating oils, a critical quality metric for petroleum products. By utilizing two test cylinders and advanced heating mechanisms, it ensures reproducible and trustworthy results, aiding industries in maintaining oil integrity. Its application spans quality assurance, product development, and research, making it an essential tool for manufacturers and service providers in the petroleum sector.

Reliable Power and Operating Standards

Designed for ease of use, the equipment operates seamlessly with a 230 Volt, 50 Hz, single phase AC supply found commonly in Indian industrial setups. Its robust design supports continual use and delivers consistent outcomes, making it suitable for demanding laboratory environments. The apparatus is built to meet both national and international petroleum testing standards.

FAQs of Foaming Characteristics of Lubricating Oil -(Two Test Cylinder):

Q: How does the Two Test Cylinder Foaming Characteristics apparatus work?

A: The apparatus determines the foaming tendency of lubricating oil by agitating oil samples in two separate test cylinders and observing foam formation and dissipation. This method replicates conditions oils face in real-world applications, helping assess their suitability for use.Q: What are the primary benefits of using this petroleum testing equipment?

A: This equipment ensures reliable assessment of lubricating oils, helping prevent operational issues such as excessive foaming and air entrainment. Accurate foaming analysis supports product quality, prolongs machinery life, and maintains efficiency in engines and hydraulic systems.Q: When should lubricating oil be tested for foaming characteristics?

A: It is recommended to test lubricating oils before use in any critical machinery, after formulation adjustments, or routinely as part of quality control procedures in oil manufacturing and processing facilities.Q: Where is the Foaming Characteristics of Lubricating Oil (Two Test Cylinder) apparatus typically used?

A: This apparatus is commonly used in petroleum laboratories, oil manufacturing plants, quality control departments, and research institutes engaged in oil formulation and testing, particularly throughout India.Q: What is the testing process with this equipment?

A: Operators introduce a measured sample of lubricating oil into each of the two test cylinders, set the equipment to the required operating parameters (using the 230 Volt, 50 Hz, single phase AC power), and monitor foam creation and collapse according to standardized test procedures.Q: How is the apparatus powered and what are its electrical requirements?

A: The apparatus runs on a standard 230 Volt, 50 Hz, single phase AC supply, ensuring compatibility with typical Indian and international laboratory electrical setups.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Petroleum Testing Equipments Category

Boiling Point Of Engine Coolants

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Frequency : 50 Hz

Automation Grade : SemiAutomatic

Power Supply : 230 Volts. 50 Hz, Single phase, AC Supply

Redwood Viscometer Multiple Apparatus - Combined Model

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Frequency : 50 Hz

Automation Grade : Manual

Power Supply : 230 V AC, 50 Hz, Single Phase

Cold Filter Plugging Point Apparatus - (Manual Operation)

Price Range 1.00 - 1.00 INR / Piece

Minimum Order Quantity : 1 , , Piece

Frequency : 5060 Hertz (HZ)

Automation Grade : Manual

Power Supply : 230 Volts, 50 Hz, Single phase,AC Supply

Reid Vapour Pressure Test Apparatus

Minimum Order Quantity : 1 , , Piece

Frequency : 5060 Hertz (HZ)

Automation Grade : Semi Automatic

Power Supply : 230 Volts, 50 Hz, Single Phase AC Supply

|

EIE INSTRUMENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry