Boiling Point Of Engine Coolants

Price 1.00 INR/ Piece

Boiling Point Of Engine Coolants Specification

- Measuring Range

- 75C to 150C

- Features

- Over-temperature protection, fast measurement

- Automation Grade

- Semi-Automatic

- Voltage

- 230 Volt (v)

- Gas Pressure

- Atmospheric

- Interface Type

- Analog/Digital

- Display Type

- Digital Display

- Frequency

- 50 Hz

- Equipment Type

- Boiling Point Tester

- Accuracy

- 0.5C

- Specimen Size

- 50 ml to 100 ml

- Temperature

- Ambient to 150C

- Port Size

- Standard fitting

- Response Time

- Immediate (Less than 10 seconds)

- Application

- Engine Coolant Boiling Point Measurement

- Resolution

- 0.1C

- Test Range

- 75C to 150C

- Max Height

- 210 mm

- Operating Voltage

- 230 Volt AC

- Number of Specimens

- Single

- Humidity

- 10-90% RH

- Power Supply

- 230 Volts. 50 Hz, Single phase, AC Supply

- Mounting Type

- Bench-top

- Usage

- Automotive, Laboratory

- Capacity

- 100 ml

- Machine Weight

- Approx. 12 Kg

- Test Speed

- Manual

- Test Width

- Standard

- Test Stroke

- Variable

- Control Mode

- Digital

- Data Logging

- Manual

- Measurement Principle

- Boiling Point Elevation

- Heating Element

- Stainless steel immersion heater

- Safety Features

- Thermal cut-off, insulated handles

- Outer Material

- Powder coated metal body

- Heating Time

- 3-5 minutes per test

- Sample Type

- Liquid (Coolants)

- Weight Without Accessories

- 10 Kg

- Protection Class

- IP-20

- Ambient Working Temperature

- 10°C to 40°C

- Sensor Type

- PT100 Temperature Sensor

Boiling Point Of Engine Coolants Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- Ahmedabad

- Payment Terms

- Cheque, Letter of Credit (L/C), Cash Against Delivery (CAD), Telegraphic Transfer (T/T), Cash in Advance (CID), Cash Advance (CA)

- Supply Ability

- 150 Pieces Per Year

- Delivery Time

- 4 Week

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden packing with strong base

- Main Export Market(s)

- Australia, South America, Middle East, Asia, Africa

- Main Domestic Market

- All India

- Certifications

- ISO 9001 : 2015

About Boiling Point Of Engine Coolants

Product details

| Frequency | 50-60 Hz |

| Packaging Type | Wooden Box |

| Automation Grade | Semi-automatic |

| Brand | EIE |

| Voltage | 220-240V |

| Power Source | Electric |

| Model Name/Number | EIE-PTEC-142 |

High Precision Engine Coolant Testing

Our Boiling Point Tester provides reliable and fast measurements for engine coolant analysis. Its digital control, PT100 temperature sensor, and stainless steel heating element ensure accuracy and repeatability. With safety features like over-temperature protection and insulated handles, this equipment supports routine testing in automotive and laboratory settings, making it an indispensable tool for maintaining coolant standards and engine performance.

User-Friendly Design and Operation

The testers powder-coated metal body offers durability, while the bench-top mounting and semi-automatic control mode simplify operation. A simple manual test process enables straightforward data logging, and the immediate response time (<10 seconds) enhances efficiency. With a capacity of up to 100 ml and a standard specimen size range of 50100 ml, it is suitable for a variety of sample types.

FAQs of Boiling Point Of Engine Coolants:

Q: How does the Boiling Point Tester measure the coolants boiling point?

A: The tester uses the principle of boiling point elevation. It heats the coolant sample using a stainless steel immersion heater and utilizes a PT100 sensor to accurately measure the temperature at which boiling occurs, providing a digital readout within the range of 75C to 150C.Q: What types of engine coolants can be tested with this equipment?

A: This device is suitable for testing any liquid automotive engine coolant sample with a volume between 50 ml and 100 ml, making it compatible with most standard coolant formulations used in vehicles.Q: When should engine coolant be tested for its boiling point?

A: Engine coolant should be tested during routine maintenance, after coolant replacement, or whenever overheating issues are suspected, ensuring engine protection and optimal performance.Q: Where can this boiling point tester be used?

A: The tester is designed for benchtop installation in automotive workshops, research laboratories, quality control departments, and educational institutions, providing flexibility for various testing environments.Q: What is the process for operating the tester?

A: To operate, fill the sample chamber with 50100 ml of coolant, start the heating process, and monitor the digital display. The result is available in 35 minutes. Data must be recorded manually. Safety features such as thermal cut-off and insulated handles ensure secure operation.Q: What are the main benefits of using this boiling point tester?

A: Users benefit from high accuracy (0.5C), rapid heating, immediate temperature response, and built-in safety features, ensuring both convenience and reliable results for coolant performance assessment.Q: Is the device suitable for export or industrial supply in India?

A: Yes, the tester is available for export, and is widely used by manufacturers, service providers, suppliers, and traders across India due to its robust design and compliance with industry standards.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

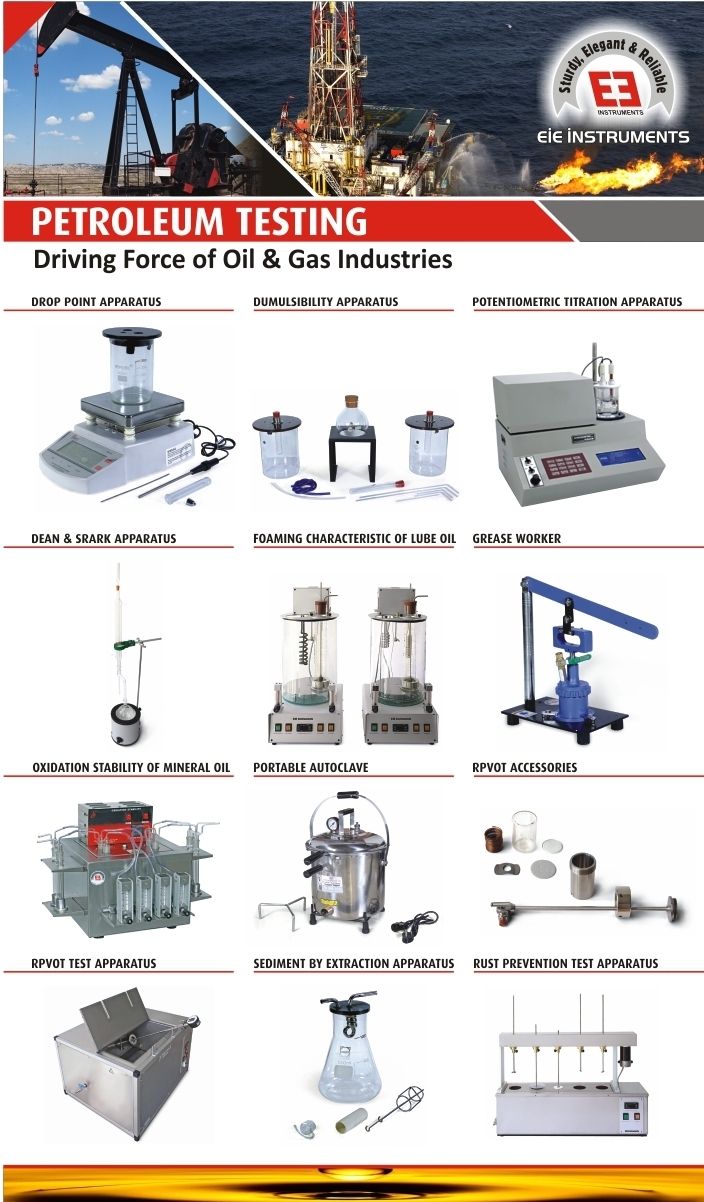

More Products in Petroleum Testing Equipments Category

Petroleum Testing Equipment

Minimum Order Quantity : 1 Piece

Automation Grade : Semiautomatic

Features : Thermostatic control, easy sample placement, corrosionresistant build

Product Type : OIL SEPARATION FROM LUBRICATING GREASE AT ELEVATED TEMPERATURE

Usage : Petroleum Testing Equipment

Power Supply : 230V AC, 50 Hz

Freezing Point Apparatus - With In-Built Refrigeration System

Minimum Order Quantity : 1 Piece

Automation Grade : Automatic

Features : Accurate results, Robust construction, Efficient working

Product Type : Freezing Point Apparatus

Usage : Laboratory

Power Supply : 230 Volts, 50 Hz, Single phase, AC Supply

Cold Filter Plugging Point Apparatus - Four Test Wells

Minimum Order Quantity : 1 Piece

Automation Grade : Semi Automatic

Features : Accurate results, Robust construction, Efficient working

Product Type : Cold Filter Plugging Point Apparatus

Usage : Laboratory

Power Supply : 230 Volts,50 Hz, Single phase, AC Supply

Drop Point Apparatus for Lubricating Grease

Minimum Order Quantity : 1 Piece

Automation Grade : Semi Automatic

Features : Accurate results, Robust construction, Efficient working

Product Type : Drop Point Apparatus for Lubricating Grease

Usage : This test method covers the determination of the dropping point of lubricating grease

Power Supply : 230 Volts, 50 Hz, Single phase, AC Supply

|

EIE INSTRUMENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry