Redwood Viscometer Multiple Apparatus - Combined Model

Price 1.00 INR/ Piece

Redwood Viscometer Multiple Apparatus - Combined Model Specification

- Display Type

- Manual Stopwatch (Optional Digital Stopwatch)

- Power Supply

- 230 V AC, 50 Hz, Single Phase

- Test Range

- 20 to 2000 seconds (Redwood No.1 and No.2)

- Specimen Size

- 50 ml (Sample Volume)

- Mounting Type

- Bench-top

- Humidity

- Up to 80% RH (Non-Condensing)

- Port Size

- Standard Jet: Size 10 (Redwood No.1) & Size 3 (Redwood No.2)

- Response Time

- Immediate (Manual Observation)

- Features

- Combined assembly with both Redwood No.1 and No.2 jets, brass bath, insulated body, stirring arrangement, easy draining, manual & digital models available

- Frequency

- 50 Hz

- Max Height

- Approx. 400 mm

- Measuring Range

- 1.6 to 537 Stokes (No.1 Jet), 34 to 6772 Stokes (No.2 Jet)

- Application

- Determination of kinematic viscosity of petroleum products

- Automation Grade

- Manual

- Equipment Type

- Redwood Viscometer Multiple Apparatus - Combined Model

- Accuracy

- 0.2% of Reading

- Number of Specimens

- Single Specimen at a Time

- Resolution

- 1 Second

- Temperature

- Ambient to 100C with Heating Bath

- Operating Voltage

- 230 V AC

- Usage

- Laboratory, Research, Oil Testing

- Capacity

- Dual Jet: Redwood No.1 (Low Viscosity) & Redwood No.2 (High Viscosity)

- Machine Weight

- Approx. 11 kg

- Test Speed

- Manual (Gravity-Driven)

- Control Mode

- Manual Operation

- Timer

- Stopwatch Supplied (Digital Stopwatch Optional)

- Compliance Standards

- IS: 1448 (P:62) & IP 70

- Stirring Mechanism

- Manual Stirring Rod

- Cover Type

- Removable Lid with Handle

- Calibration

- Supplied with Jet Cleaning Wire and Calibration Report

- Bath Capacity

- Approx. 5 Liters

- Safety Features

- Overheat Protection Provided

- Sample Cup Material

- Brass, Precision Machined

- Drainage Facility

- Integrated Sample Drain for Easy Cleaning

- Heating Type

- Electrical Immersion Heater with Regulator or Thermostatic Control

- Material of Construction

- Brass Bath with Insulated Exterior and Stainless Steel Lid

Redwood Viscometer Multiple Apparatus - Combined Model Trade Information

- Minimum Order Quantity

- 1 Piece

- Packaging Details

- Wooden Box

About Redwood Viscometer Multiple Apparatus - Combined Model

This Multiple Redwood viscometer is designed for viscosity tests of petroleum Products.It consists, One Red Wood No.1 cup and One Red Wood No. 2 cup are installed in the bath

Further details available on our website.

The Price mentioned here are subject to change as per the capacity, specifications and application of the user.

Reliable Dual-Jet Design for Versatile Applications

The Redwood Viscometer Combined Model is equipped to use both Redwood No.1 and No.2 jets, making it adept at determining a broad range of kinematic viscosities. This dual-jet system ensures suitability for low and high viscosity petroleum samples, providing comprehensive coverage for exploratory research to routine laboratory analysis.

Superior Material Construction and Safety Features

Crafted with a precision-machined brass bath, insulated exterior, and stainless steel lid, this viscometer ensures long-lasting durability and thermal efficiency. Overheat protection and thermostatic temperature control guarantee safe and consistent operation, while integrated drainage simplifies post-test cleaning and maintenance.

Accurate and Flexible Manual Operation

Manual operation mode with an included stopwatch achieves a fine resolution of 1 second, allowing immediate response and accurate result recording. The optional digital stopwatch and easy manual stirring make the device user-friendly while preserving result consistency required for standardized oil and fuel testing.

FAQs of Redwood Viscometer Multiple Apparatus - Combined Model:

Q: How is the Redwood Viscometer Multiple Apparatus used in viscosity determination?

A: The apparatus is used by placing a 50 ml petroleum sample in the brass cup, selecting the suitable jet (No.1 for low, No.2 for high viscosity), and heating the bath to the desired temperature. Using the manual stirring rod and the supplied stopwatch, the time taken by the sample to flow through the jet is measured, from which the kinematic viscosity is calculated.Q: What are the benefits of the combined Redwood No.1 and No.2 jet model?

A: The combined model allows users to test both low and high viscosity samples without switching between separate instruments, saving time and resources. This dual capability makes it ideal for laboratories and research centers handling diverse petroleum products.Q: Where can the Redwood Viscometer Multiple Apparatus be installed and used?

A: Designed as a bench-top instrument, the viscometer is suitable for use in laboratories, research facilities, and oil testing stations. Its sturdy construction and moderate size facilitate convenient setup on standard laboratory benches.Q: What safety features are integrated in this viscometer?

A: The viscometer includes overheat protection to prevent thermal accidents and an insulated exterior to ensure operator safety. These features help guarantee reliable and secure operation during lengthy test processes.Q: What is the process for cleaning the viscometer after a test?

A: A built-in drainage facility allows for straightforward removal of the sample after testing. The brass bath and removable lid further ease access for internal cleaning, while the supplied jet cleaning wire helps maintain the jets in optimal condition.Q: Can both manual and digital stopwatches be used with this equipment?

A: Yes, the viscometer is supplied with a manual stopwatch for timing sample flow. For added convenience and improved accuracy, users may also opt for an optional digital stopwatch.Q: How does the apparatus ensure measurement accuracy and consistency?

A: The viscometers precision-machined brass components, thermostatic temperature control, and supplied calibration report help maintain high accuracy (0.2% of reading). Regular cleaning with the provided jet wire further ensures consistent measurement results as per IS: 1448 (P:62) and IP 70 standards.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Petroleum Testing Equipments Category

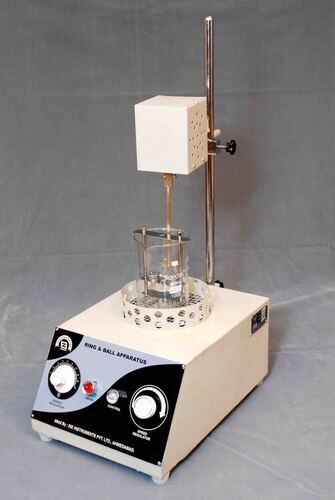

RING AND BALL APPARATUS ELECTRICALLY OPERATED

Minimum Order Quantity : 1 Piece

Product Type : Ring and Ball Apparatus Electrically Operated

Automation Grade : Semiautomatic

Features : Electrically heated bath, Two steel balls, Brass rings, Temperature control

Usage : Petroleum Testing Equipment

Grease Worker Single Cup

Minimum Order Quantity : 1 , , Piece

Product Type : Grease Worker Single Cup

Automation Grade : Semi Automatic

Features : Accurate results, Robust construction, Efficient working

Usage : Petroleum Testing Equipment

Copper Strip Corrosion Test Apparatus - Digital

Price Range 1.00 - 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : Copper Strip Corrosion Test Apparatus

Automation Grade : Semi Automatic

Features : Accurate results, Robust construction, Efficient working

Usage : Laboratory

Demulsibility Test Apparatus-(Water Separability Test Apparatus)

Price Range 1.00 - 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : Demulsibility Test Apparatus

Automation Grade : Semi Automatic

Features : Accurate results, Robust construction, Efficient working

Usage : Laboratory

|

EIE INSTRUMENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry