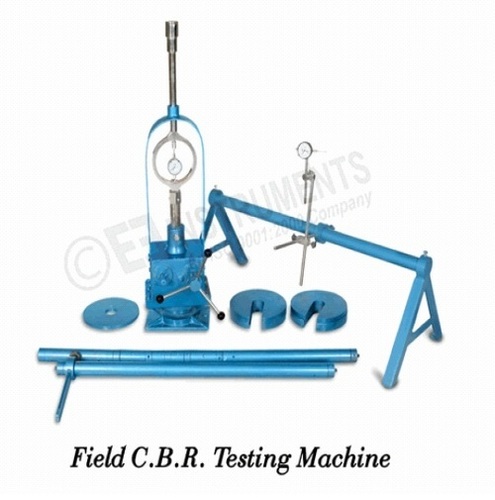

Field Cbr Test Apparatus With Proving Ring and Dial Gauge

Price 73000.00 INR/ Piece

Field Cbr Test Apparatus With Proving Ring and Dial Gauge Specification

- Usage

- Soil Testing Equipment

- Material

- Stainless Steel

- Application

- Used for the in-situ determination of the bearing capacity of soils used in road construction

- Automation Grade

- Semi Automatic

- Product Type

- Field CBR Test Apparatus

- Features

- Accurate results, Robust construction, Efficient working

- Weight

- 120 Kilograms (kg)

- Dimension (L*W*H)

- 600 X 1300 X 600 (L X W X D) mm Millimeter (mm)

- Machine Weight

- 120 Kilograms (kg)

Field Cbr Test Apparatus With Proving Ring and Dial Gauge Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 100 Pieces Per Month

- Delivery Time

- 4 Week

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Box / Corrugated Box

- Certifications

- ISO 9001 : 2015

About Field Cbr Test Apparatus With Proving Ring and Dial Gauge

Used for the in-situ determination of the bearing capacity of soils used in road construction. The complete set is housed in a strong carrying case.

Brief construction details :

- Mechanical screw loading jack, 100 KN capacity with U bracket and swivel head.

- Penetration piston of 50 mm diameter threaded at upper end.

- Extension rods set consisting of 50 cm and 100 cm

- Used as spacers between the proving ring and penetration piston.

Further details availableon our website.

The Price mentioned here are subject to change as per the capacity,specifications and application of the user.

Precision Equipment for Soil Analysis

This Field CBR Test Apparatus stands out for its reliable construction and dependable measurements. Thanks to the integrated proving ring and dial gauge, users achieve high-precision readings essential for crucial roadwork soil assessments. Its sturdy design is ideal for regular field use and long-term performance.

Comprehensive Supplier Solutions

Produced by experienced manufacturers, exporters, service providers, and traders in India, this CBR apparatus comes backed with technical support and after-sales service. The supplier provides all necessary training and guidance, ensuring users can efficiently perform soil bearing capacity tests anywhere required.

FAQs of Field Cbr Test Apparatus With Proving Ring and Dial Gauge:

Q: How is the Field CBR Test Apparatus with Proving Ring and Dial Gauge used in soil testing?

A: The apparatus is employed to conduct in-situ California Bearing Ratio (CBR) tests, measuring the bearing capacity of soil directly on-site. The proving ring and dial gauge help record penetration resistance accurately as force is applied, offering immediate, actionable data essential for road construction projects.Q: What are the key components of this CBR Test Apparatus?

A: The primary elements of this testing system include the main frame, a proving ring for force measurement, a dial gauge for penetration tracking, and associated fixtures. These components work together to ensure reliable and consistent soil strength evaluation.Q: When should the Field CBR Test Apparatus be utilized during a road construction project?

A: This apparatus should be used during the geotechnical investigation phase and prior to pavement or road layer construction. Early determination of soil bearing capacity is crucial to inform design decisions and guarantee the stability of the constructed roadway.Q: Where can this Field CBR Test Apparatus be effectively deployed?

A: Designed for use at construction sites, the apparatus is most effective in the field where actual roadwork is planned. Its portability and robust build allow for direct on-site testing, eliminating the need to transport large soil samples back to laboratories.Q: What is the process for operating this CBR testing equipment?

A: After positioning the apparatus at the desired location, the soil sample is prepared and penetrated by the plunger. The proving ring measures the applied load, while the dial gauge tracks penetration depth. The collected data is then analyzed to determine the soils bearing capacity.Q: What are the main benefits of using this CBR Test Apparatus with a proving ring and dial gauge?

A: Key advantages include precise and repeatable measurements, rugged construction suitable for field conditions, and ease of use by trained personnel. These factors contribute to efficient site investigations, supporting safer and more durable road construction designs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

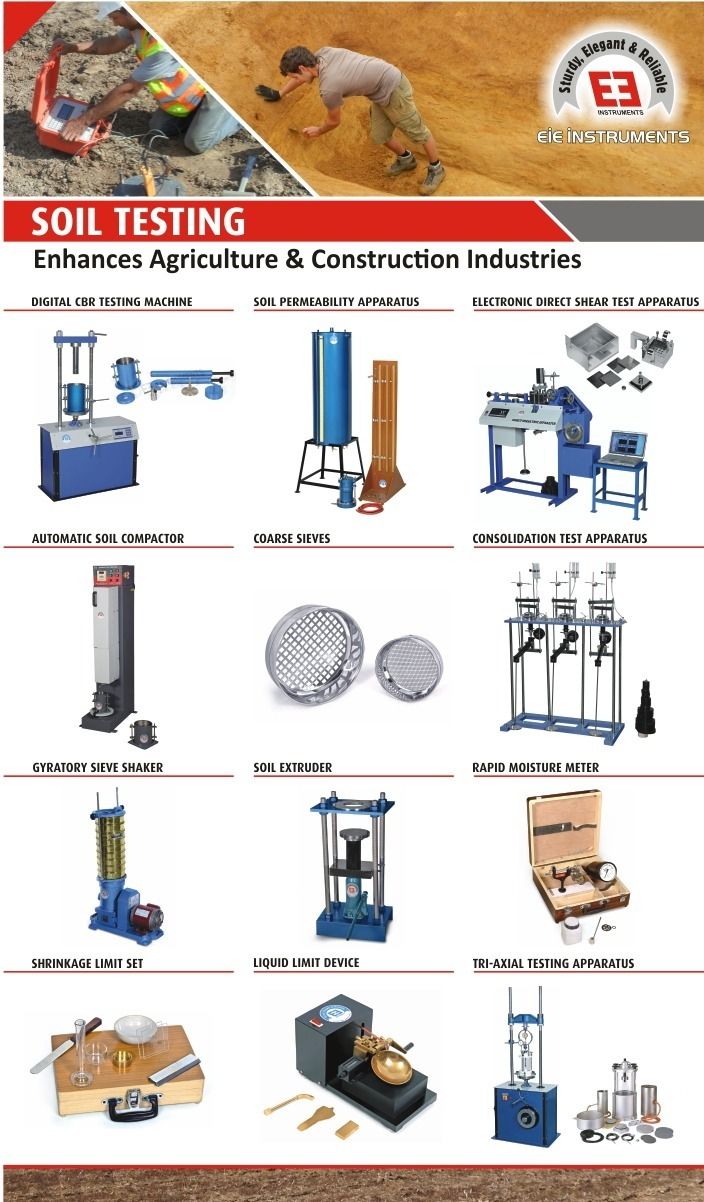

More Products in Soil Testing Equipments Category

Direct Shear Apparatus-Motorised - Single Speed - Electronic Digital

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Laboratory/Test Room

Application : Soil Shear Strength Test

Features : Motorized, Single Speed, Electronic Digital, Autostop facility, Overload protection

Frequency : 50 Hz

Universal Triaxial Cell

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Lab testing for soil samples

Application : Soil mechanics testing, geotechnical engineering

Features : Corrosionresistant chamber, interchangeable parts

Frequency : 50 Hz

Constant Pressure System (Oil Water) - For Triaxial Test Apparatus

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Laboratory geotechnical testing

Application : For triaxial test apparatus in soil mechanics/geotechnical investigations

Features : Overpressure safety valve, low fluid level alarm, corrosionresistant construction

Frequency : 50 Hz

Consolidation Apparatus-Single Gang

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Laboratory, geotechnical investigation

Application : Determination of soil consolidation properties in geotechnical engineering

Features : Rigid frame, corrosion resistant finish, stable loading arrangement, easy displacement readings

Frequency : 50 Hz

|

EIE INSTRUMENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry