ELASTIC RECOVERY MOULD WITH BASE PLATE

Price 1.00 INR/ Piece

ELASTIC RECOVERY MOULD WITH BASE PLATE Specification

- Accuracy

- Conforms to IS 12039

- Features

- Corrosion-resistant, detachable brass mould, complete with base plate

- Temperature Resistance

- Up to 60C melting point

- Control Type

- Manual

- Shape

- Rectangular

- Usage

- Bitumen Testing Equipment

- Type

- Elastic Recovery Mould with Base Plate

- Dimension (L*W*H)

- Overall Length 470 mm approx (Moulds are 250 x 25 x 25 mm each)

- Product Type

- Elastic Recovery Mould

- Equipment Type

- Bitumen Testing Equipment

- Equipment Materials

- Stainless Steel, Brass

- Material

- Stainless Steel

- Application

- Determining elastic recovery of bitumen

- Finish

- Polished

- Number of Moulds

- 2 moulds per set

- Base Plate Size

- Sufficient size to accommodate both moulds

- Mould Size

- 250 x 25 x 25 mm

ELASTIC RECOVERY MOULD WITH BASE PLATE Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 500 Pieces Per Month

- Delivery Time

- 4 Week

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Box / Corrugated Box

- Certifications

- ISO 9001 : 2015

About ELASTIC RECOVERY MOULD WITH BASE PLATE

Construction Details:

- Made of brass OR Gunmetal material

- The shape, dimensions and tolerances as shown in picture

- The ends b and b are known as clips, and the parts a and a are known as sides of the mould.

- The dimensions of the mould will be such that, when it is properly assembled, it will form a briquette specimen.

Further details availableon our website.

The Price mentioned here are subject to change as per the capacity,specifications and application of the user.

Precision in Bitumen Testing

Our Elastic Recovery Mould with Base Plate allows for highly accurate measurement of bitumens elastic recovery, essential for evaluating the flexibility and performance of road construction materials. The stainless-steel moulds, combined with a corrosion-resistant, detachable brass section, ensure consistent results while adhering to IS 12039 specification. Perfect for laboratory and on-site bitumen testing applications.

User-Friendly and Durable Construction

Crafted from premium stainless steel, the moulds boast a polished finish and a detachable brass mould for easy cleaning. The robust base plate is dimensioned to securely accommodate both moulds, facilitating a straightforward test setup. With resistance to temperatures up to 60C, this equipment is built for frequent and intensive use.

FAQs of ELASTIC RECOVERY MOULD WITH BASE PLATE:

Q: How is the Elastic Recovery Mould with Base Plate used in bitumen testing?

A: This equipment is used by filling the stainless steel moulds with bitumen sample, cooling, and subsequently stretching the specimen to measure its elastic recovery, as outlined in IS 12039 standards. The detachable design aids in easy specimen removal and cleaning after the test.Q: What benefits does the detachable brass mould and stainless steel construction provide?

A: The detachable brass mould ensures quick and safe removal of bitumen samples without damaging them, while the stainless steel construction provides excellent corrosion resistance, enhancing durability and extending service life.Q: When should bitumen elastic recovery tests be performed using this mould?

A: Elastic recovery tests are typically conducted during the development and quality control stages of bitumen production or when evaluating materials for road construction to ensure compliance with performance standards.Q: Where is this elastic recovery mould most commonly utilized?

A: It is widely used in laboratory settings, quality control departments, research institutions, and field testing by road construction authorities and contractors.Q: What is the process for conducting a test with this mould set?

A: Prepare a bitumen specimen, pour it into the assembled mould, allow proper cooling, then stretch the specimen using manual controls while observing its recovery over a set distance. Analyze results following IS 12039 procedures.Q: How does using this mould improve testing accuracy?

A: The precision manufacturing of the moulds, adherence to IS 12039, and the use of polished, corrosion-resistant materials ensure highly consistent, accurate results across multiple test cycles.Q: What makes this bitumen testing equipment suitable for repeated laboratory use?

A: Its robust stainless steel and brass construction, resistance to temperatures up to 60C, and ease of maintenance make it ideal for frequent, long-term laboratory and field testing under demanding conditions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

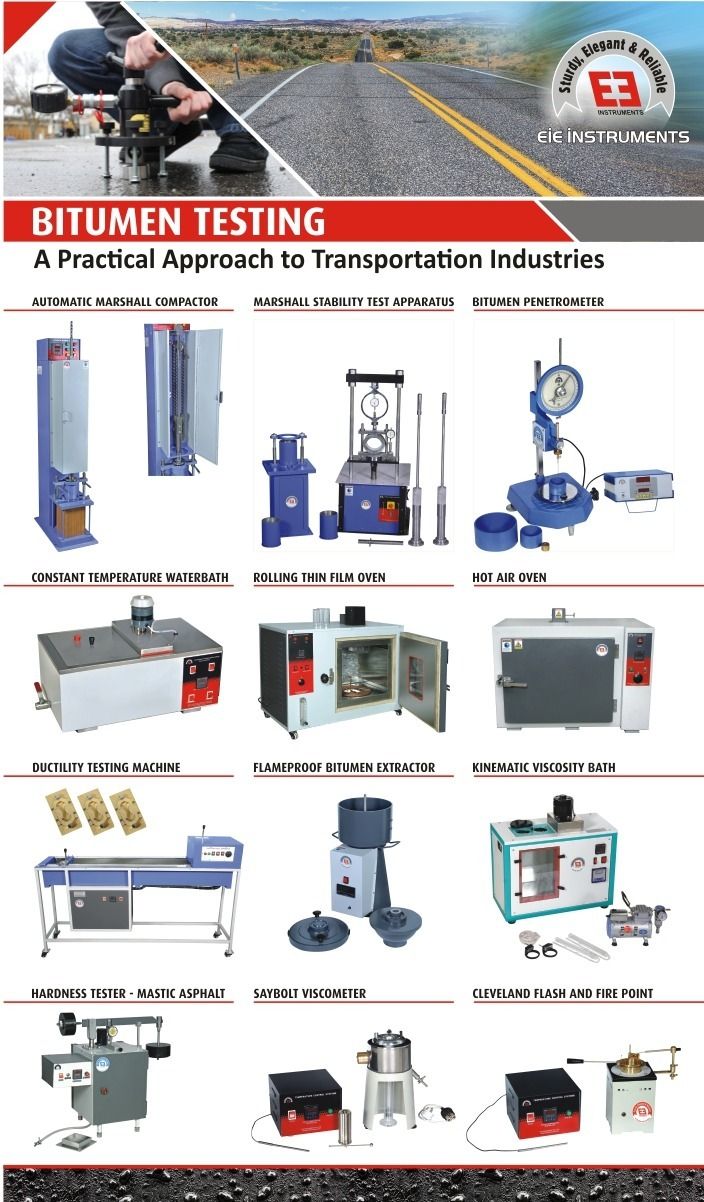

More Products in Bitumen Testing Equipments Category

Marshal Stability Testing Machine Modified- Digital

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Application : Testing the stability and flow value of bituminous mixtures

Kinematic Viscosity Bath

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Application : Used for determination of kinematic and intrinsic viscosity Of fuels, lubricants & petrochemical raw materials at constant temperatures

Usage : Bitumen Testing Equipment

Warranty : 1 Year

Product Type : Kinematic Viscosity Bath Above Ambient

Indirect Tensile Strength of Marshal Test Specimen

Price 1.00 INR / Piece

Minimum Order Quantity : 1 , , Piece

Application : The Indirect Tensile Strengthis determined by measuring the ultimate load to failure of a specimen

Usage : The Indirect Tensile Strengthis determined by measuring the ultimate load to failure of a specimen, which is subjected to a constant deformation rate of 50.8 mm/minute on its diametrical axis

Warranty : 1 Year

Product Type : INDIRECT TENSILE STRENGTH OF MARSHAL TEST SPECIMEN

PRESSURE AGEING VESSEL

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Application : The Pressure Aging Vessel (PAV) provides simulated long term aged asphalt binder for physical property testing

Usage : Bitumen Testing Equipment

Warranty : 1 Year

Product Type : PRESSURE AGEING VESSEL

|

EIE INSTRUMENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry